Rotation pump working wheel

A technology of working wheels and rotary pumps, applied to pumps, pump components, non-variable pumps, etc., can solve the problems of clumsiness and cumbersome structural design, and achieve the effect of reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

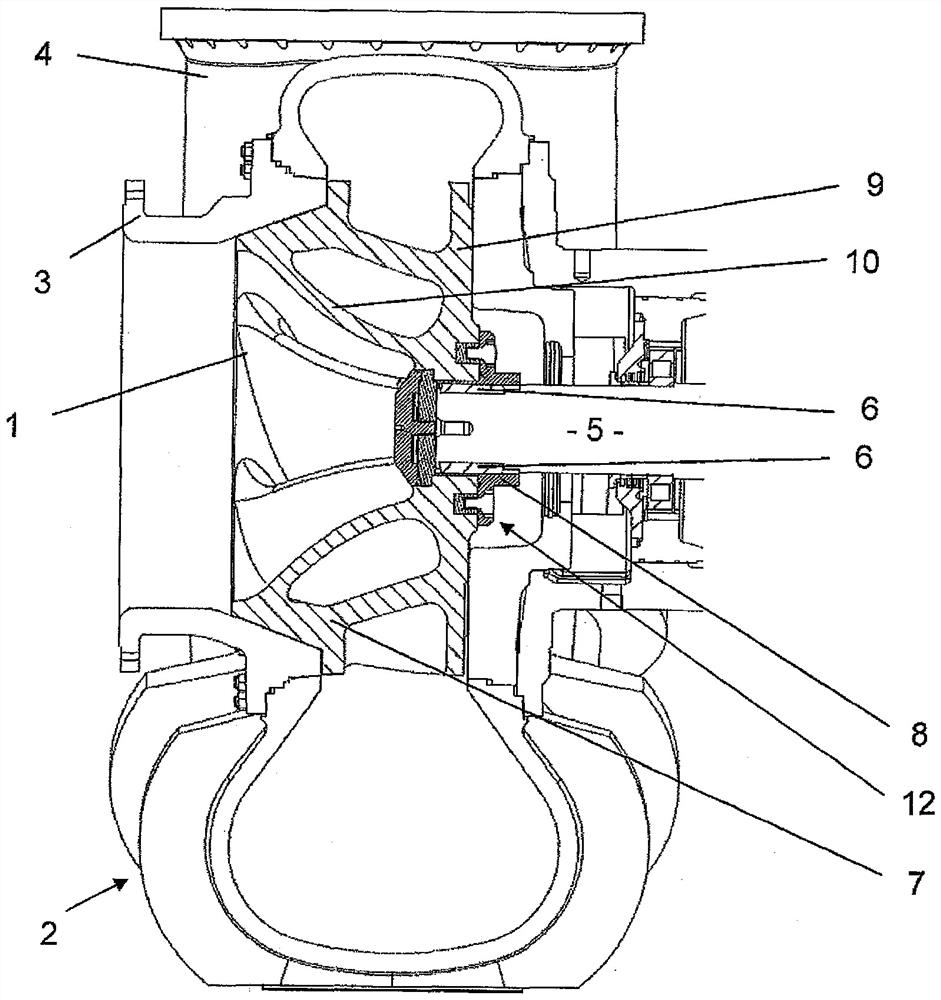

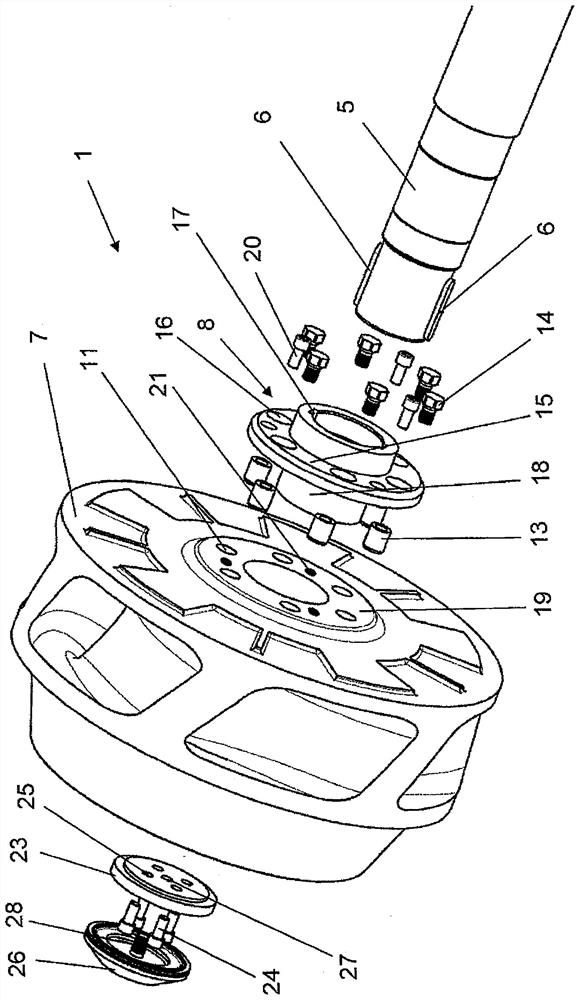

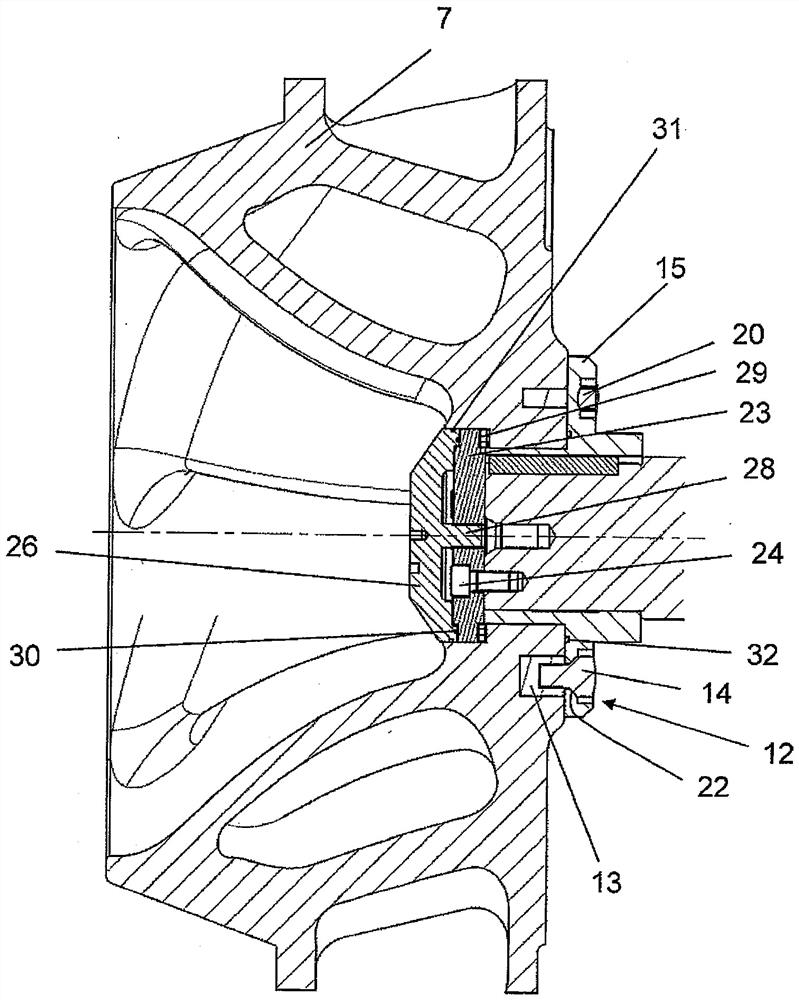

[0044] figure 1 A rotary pump impeller 1 is shown, which is arranged in a housing 2 of the rotary pump. The housing 2 comprises a suction opening 3 through which the supply medium is sucked up and supplied by means of the rotary pump impeller 1 in the direction of the outflow opening 4 and then leaves the rotary pump.

[0045] The rotary pump impeller 1 is arranged on a shaft 5 . The shaft 5 is set in rotation by a motor not shown. In this case, the torque is transmitted via the two flat keys 6 to the metallic hub part 8 and via the entraining element 12 to the non-metallic rotor part 7 of the rotary pump rotor 1 .

[0046] The rotary pump impeller 1 is formed by a non-metallic impeller part 7 and a metallic hub part 8 . In the exemplary embodiment, the non-metallic wheel part 7 is made of a ceramic-plastic-composite material, in which silicon carbide particles are embedded in a polymer matrix.

[0047] The hub 8 is made of a rust-free duplex steel casting with a ferritic-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com