Discharging equipment and discharging method

A cutting and equipment technology, used in animal feeding devices, food processing, animal husbandry, etc., can solve the problems of time-consuming and laborious, inability to accurately feed sows, affecting the number and quality of sows litter, etc. The effect of efficient, precise sow feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

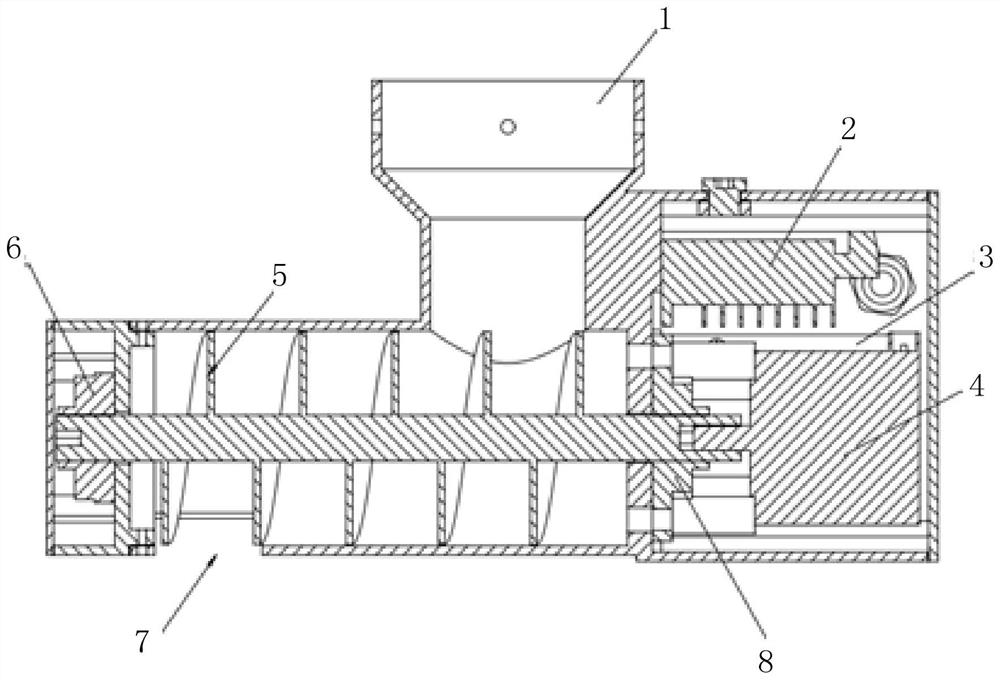

[0072] like figure 1 As shown, a feeding device includes a feeding hopper 1, a power structure and a discharging structure, the power structure includes a driver 2, a controller 3 and a stepping motor 4, and the discharging structure includes a casing, a feeding shaft 5 , the first bearing 6, the discharge port 7 and the second bearing 8;

[0073] The housing includes a horizontally arranged cylindrical cavity and a rectangular cavity, the first bearing 6 and the second bearing 8 are respectively arranged at both ends of the cylindrical cavity, and the first bearing 6, the second bearing 8 and the cylindrical cavity are The axes of the cavity coincide, one end of the feeding shaft 5 is connected to the first bearing 6 , the other end of the feeding shaft 5 is passed through the second bearing 8 , and the other end of the feeding shaft 5 is connected to the stepping motor 4 The stepping motor 4 is electrically connected with the driver 2, the driver 2 is electrically connected...

Embodiment 2

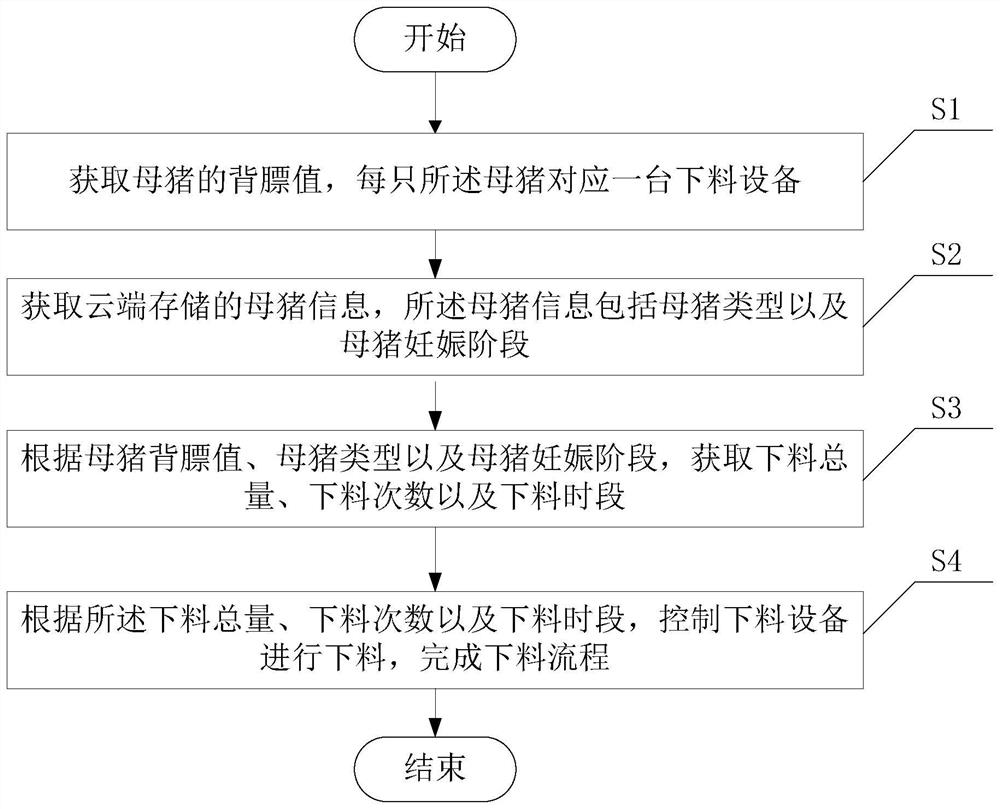

[0082] like figure 2 As shown, a blanking method based on blanking equipment includes:

[0083] S1. Obtain the back fat value of the sow, and each sow corresponds to a feeding equipment.

[0084] The sows can be raised separately, and each sow corresponds to a feeding device, so as to achieve precise feeding. The electronic ear tag of the sow can be set to ensure that the information of the sow corresponds to the feeding equipment. When the sow is migrated, it is only necessary to obtain the electronic ear tag information, and then obtain the information of the sow from the cloud, and then the feeding can be accurately cut. , improve management efficiency.

[0085] S2. Acquire sow information stored in the cloud, where the sow information includes the type of the sow and the gestational stage of the sow.

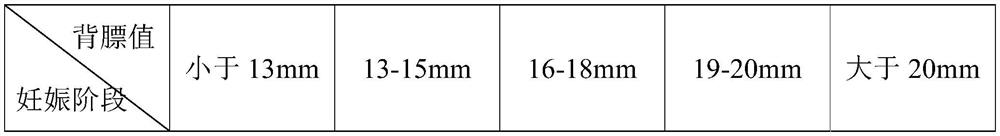

[0086] S3. According to the backfat value of the sow, the type of the sow, and the gestational stage of the sow, obtain the total amount of feeding, the number of feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com