Pineapple harvesting device with combined action of steel wire roller and rigid rod roller

A joint action, rigid rod technology, applied in the lifting device, application, harvester and other directions of agricultural machinery, can solve the problems of adjusting the harvesting angle, low level of mechanization and automation of pineapple picking, and low efficiency of manual picking, so as to achieve easy adjustment, The effect of adapting to the farmland operation environment with high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

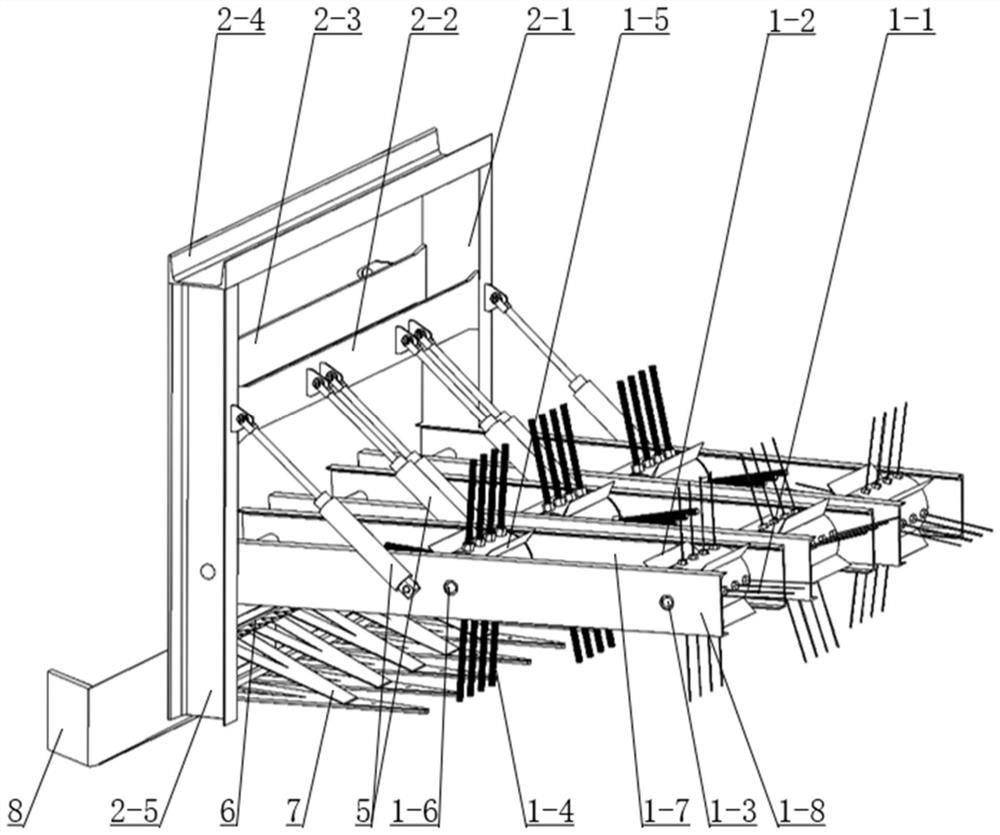

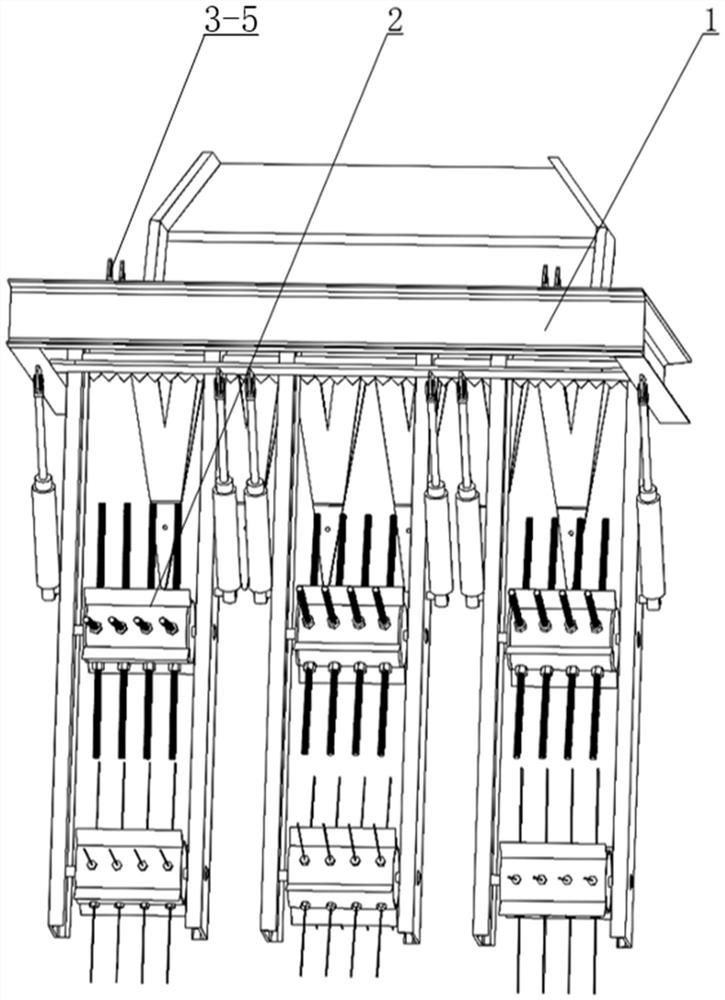

[0036] A pineapple harvesting device with a combined action of a steel wire drum and a rigid rod drum includes three double drum mechanisms 1 , an installation bracket 2 , three angle adjustment mechanisms, a fruit stem cutter 6 and a fruit supporter 7 .

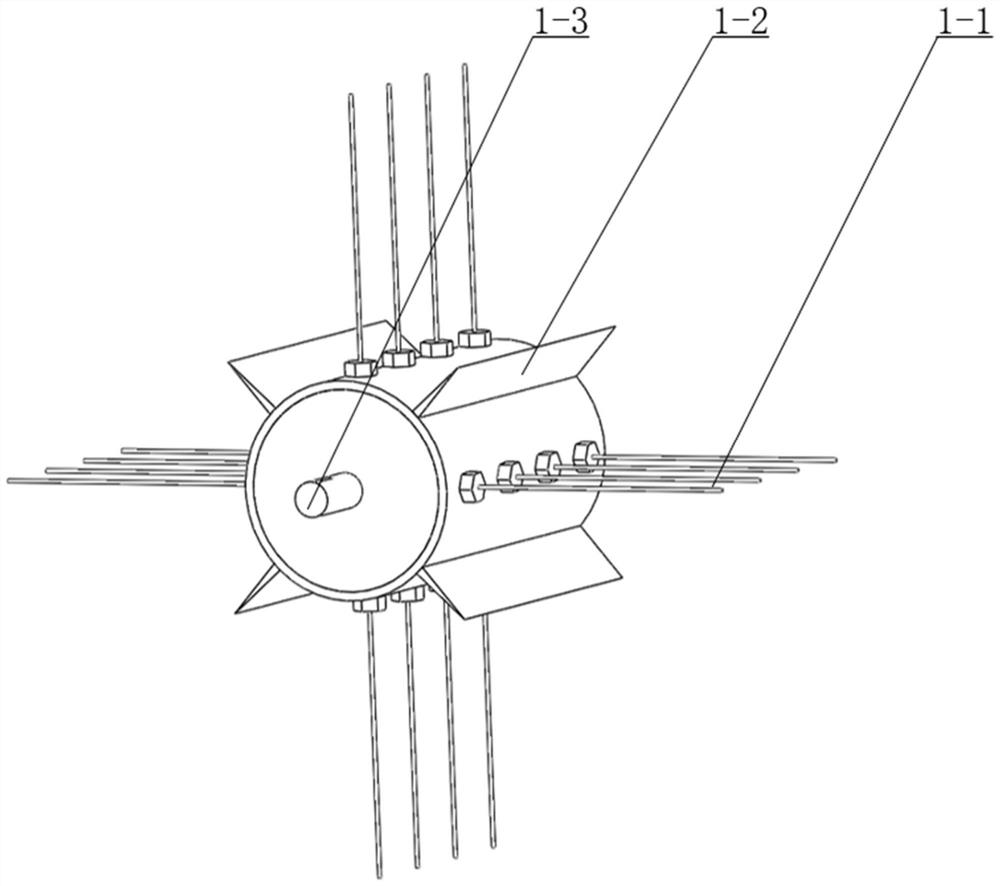

[0037] Each double drum mechanism includes wire drums, rigid bar drums, and side brackets. The side brackets include a first side bracket 1-8 and a second side bracket 1-7, and the wire drum and the rigid rod drum are respectively rotatably installed between the two side brackets. The wire drum includes a cylinder body, a wire rope 1-1, and a first blade 1-2. Multiple rows of wire ropes are evenly installed on the outer wall of the cylinder, and the first blade is arranged between two adjacent rows of wire ropes. A firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com