Drive device for vehicle

A driving device and vehicle technology, applied in transmission parts, vehicle components, electric vehicles, etc., can solve problems such as excessive load, shorten the service life of rotor shaft rotating bearings, and generate noise, and achieve the effect of reducing shaft bending stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

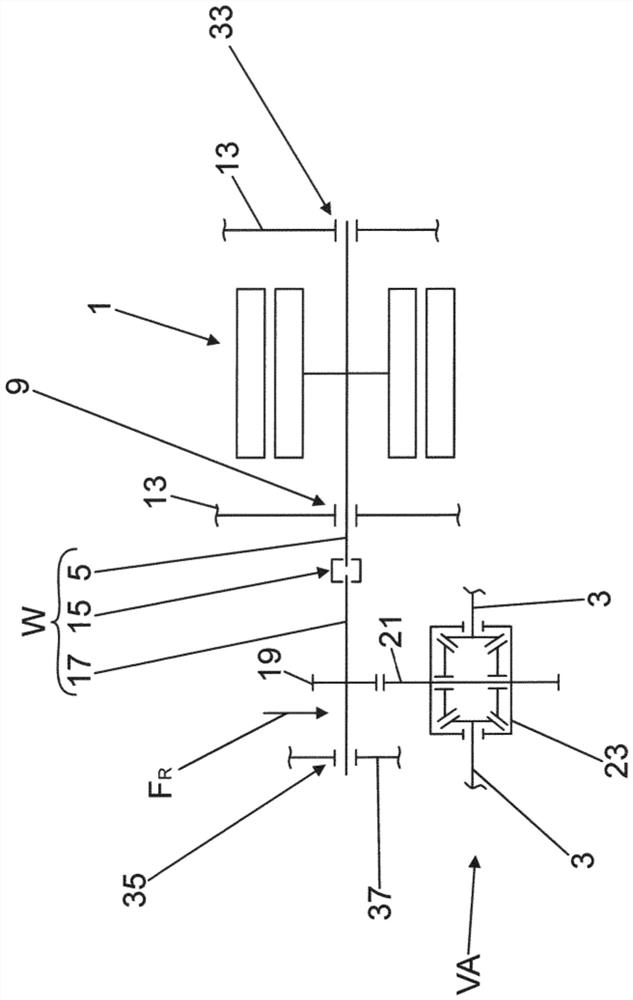

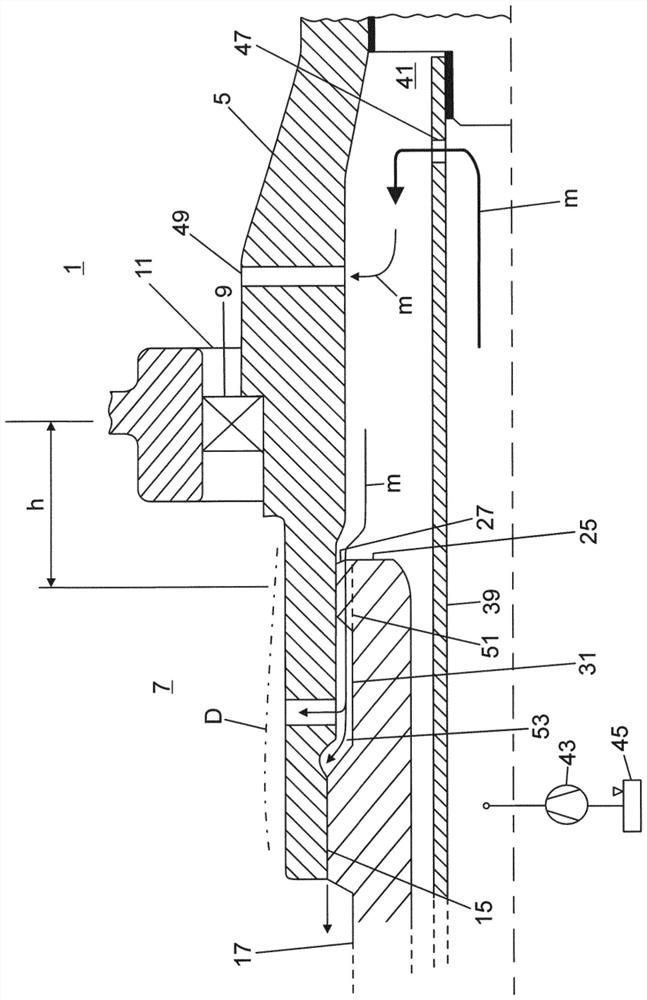

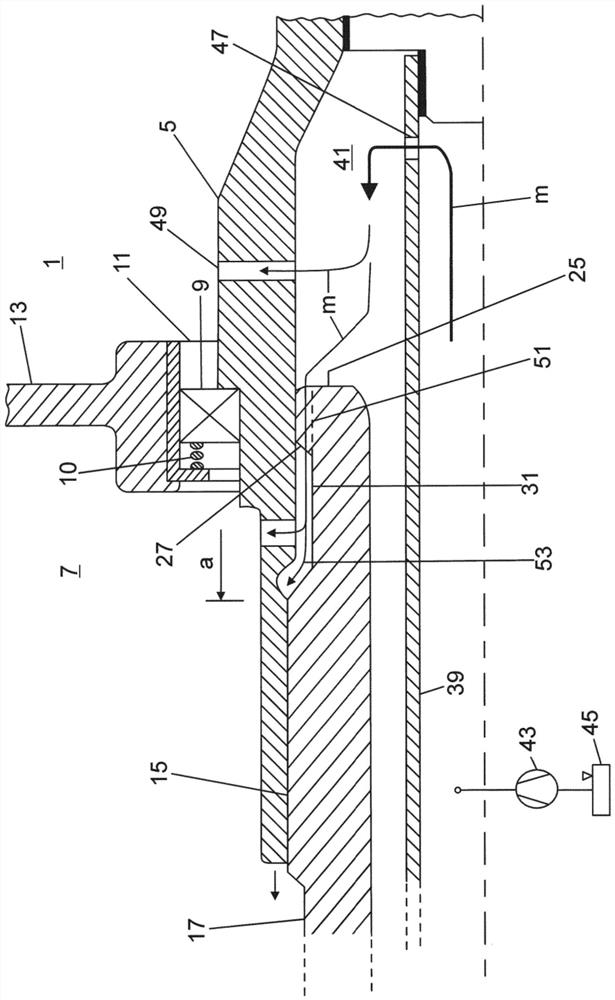

[0023] exist figure 1 A drive is shown, by means of which the front axle VA of a two-track vehicle can be driven. The front axle VA has an electric motor 1 arranged axially parallel to a flanged shaft 3 which leads to the wheels of the vehicle. The rotor shaft 5 of the motor 1 passes through the transmission 7 ( image 3 ) is connected to the two flange shafts 3 for transmission. Rotor shaft 5 - connect the rotor shaft rotating bearing 9 ( figure 1 or image 3 ) - is led out from the bearing opening 11 of the motor housing 13 and is connected to the coaxially arranged transmission drive shaft 17 via a torque-transmitting mating tooth 15 . A fixed gear 19 of the gear stage St1 of the transmission 7 is arranged on the transmission drive shaft 17 and meshes with a gear 21 on the input side of the axle differential 23 . Axle differentials 23 are driven on both sides to flanged axles 3 which lead to the wheels of the vehicle.

[0024] For the purpose of simply understanding t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com