Jelly sealing machine with heat recycling function and jelly filling and sealing process thereof

一种热量回收、封口机的技术,应用在包装、包装机、包装保护等方向,能够解决缺少清洁机构、细菌滋生、密封膜与果冻壳受热不均匀等问题,达到优化导热过程、便于清洗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

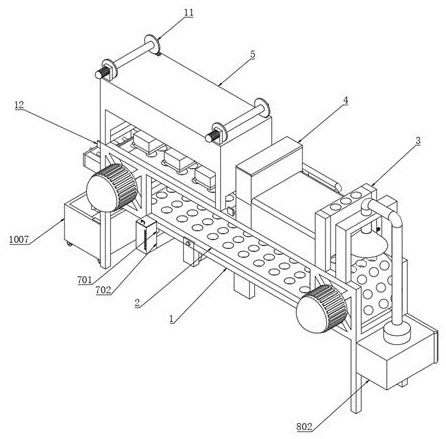

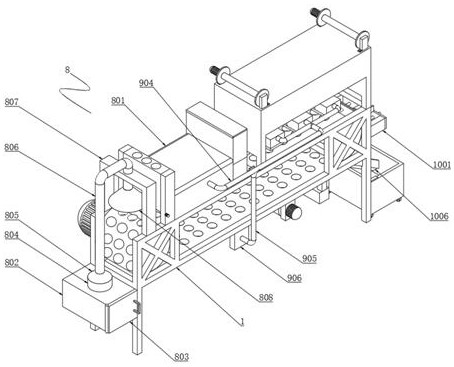

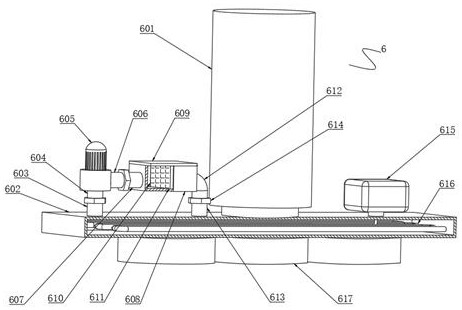

[0048] Example: as Figure 1-8 As shown, the present invention provides a technical solution. The uniform heat conduction system of the jelly sealing machine includes a fixed frame 1. In order to facilitate the staff to conduct uniform heat conduction on the pressing plate 602 and the pressing block 617, the top of the fixed frame 1 is fixedly installed with a positioning roller 12. A conveyor belt 2 is fixedly installed on one side of the fixed frame 1, a shell discharge block 3 is installed on the top edge of the fixed frame 1, and a feeding slot 4 is installed on the top of the fixed frame 1 corresponding to one side of the shell discharge block 3, and the top edge of the fixed frame 1 is installed. A sealing block 5 is installed at the top of the sealing block 5, winding rollers 11 are installed on both sides of the top of the sealing block 5, and a heat conduction mechanism 6 is fixed at the bottom end of the sealing block 5.

[0049] The heat conduction mechanism 6 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com