Large cable drum base and manufacturing method thereof

A technology of large-scale cables and production methods, which is applied in the directions of large-scale containers, manufacturing tools, load fixing, etc., can solve problems such as difficulty in placing large-scale cable reels stably and firmly fixed, unstable center of gravity of large-scale cable reels, and increasing cable manufacturing costs, etc. problem, to achieve the effect of stable center of gravity, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

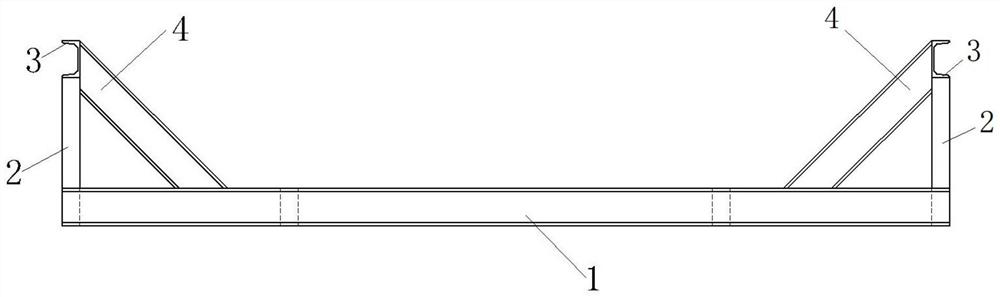

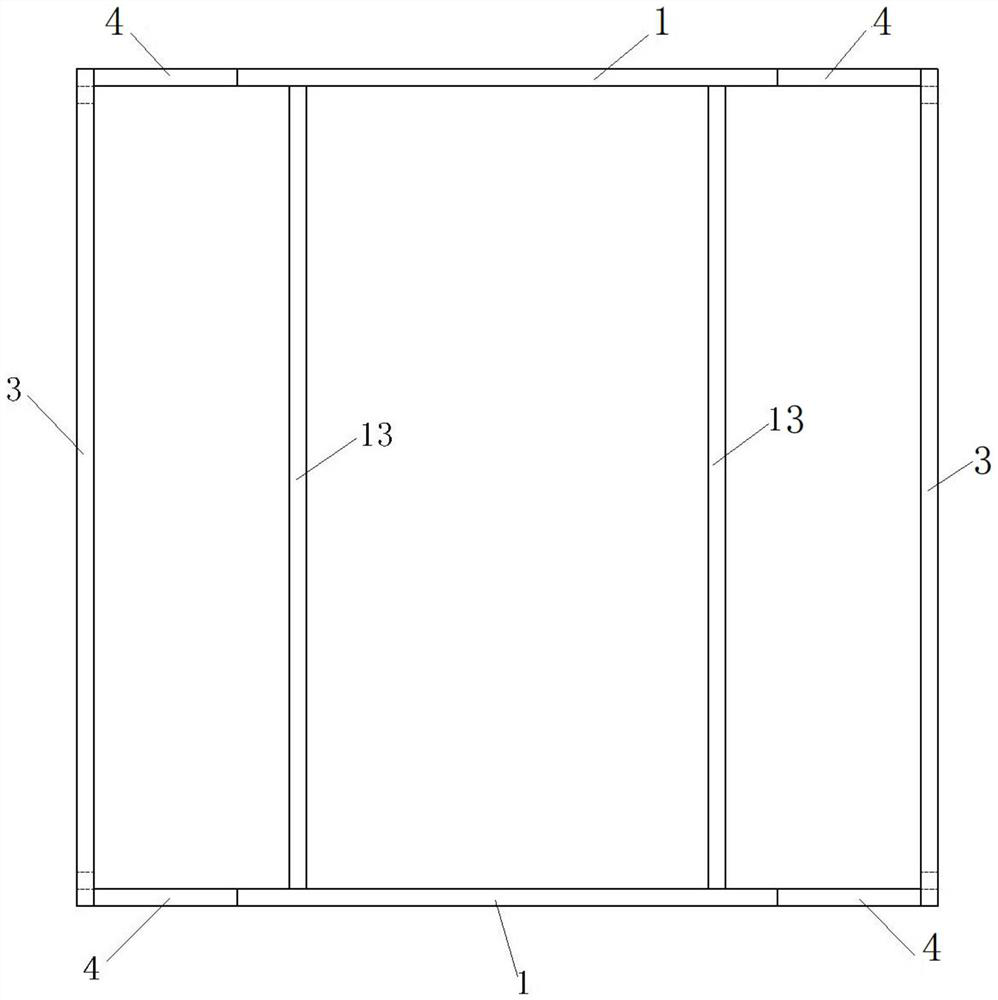

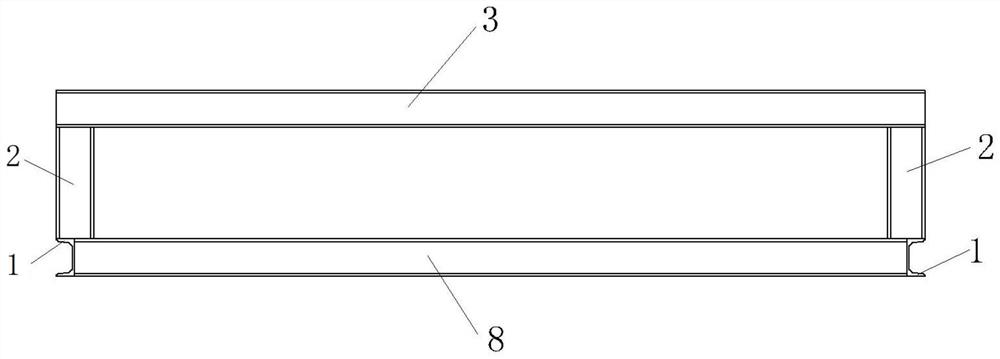

[0024] like Figure 1-3 , this embodiment provides a large-scale cable reel base, including a rectangular bottom frame formed by welding front and rear bottom rods I1 and left and right bottom rods II8, and four vertical rods 2 are vertically welded on the four corners of the bottom frame, A top rod 3 is welded between the two vertical rods 2 above the bottom rod II8 at the left and right ends of the bottom frame, and a diagonal strut 4 is welded on both ends of the bottom rod I1. The upper end of the diagonal strut 4 Welded on the top rod 3 , the diagonal strut 4 is obliquely arranged between the bottom rod I1 and the vertical rod 2 .

[0025] Two bottom rods III13 parallel to the bottom rod II are arranged between the two bottom rods I1 in the bottom frame. Bottom rod III13 is welded vertically on both sides of the vertical center line of bottom rod I1. The distance between the two bottom rods III13 depends on the two ends of the side plate of the lower cable tray when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com