Three-dimensional force flexible tactile sensor with high tangential angular resolution

A tactile sensor and resolution technology, applied in instruments, force/torque/power measuring instruments, measuring devices, etc., can solve the problems of inability to restore the sensing unit, not suitable for large-area layout, and low three-dimensional force accuracy. Achieve the effect of fewer leads, high tangential angular resolution, and improved detection resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below with reference to the accompanying drawings and embodiments.

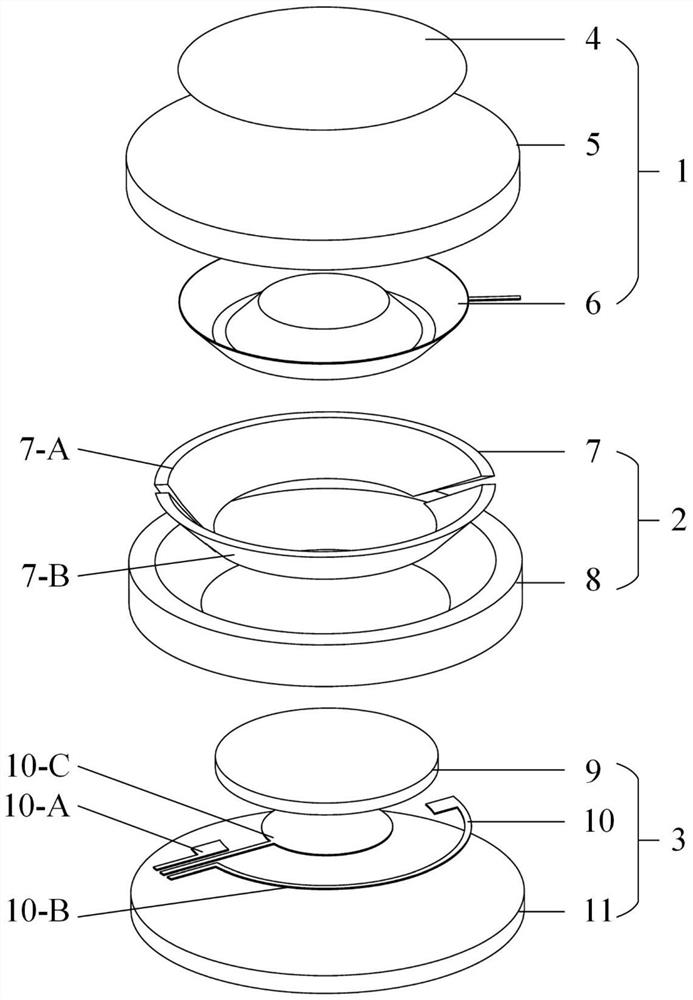

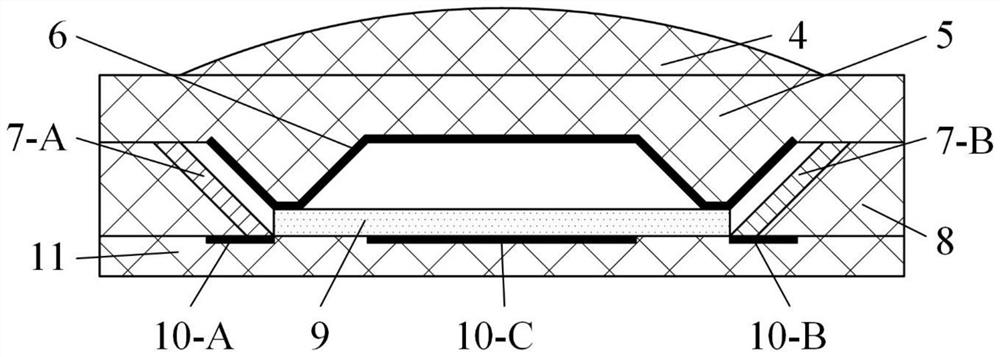

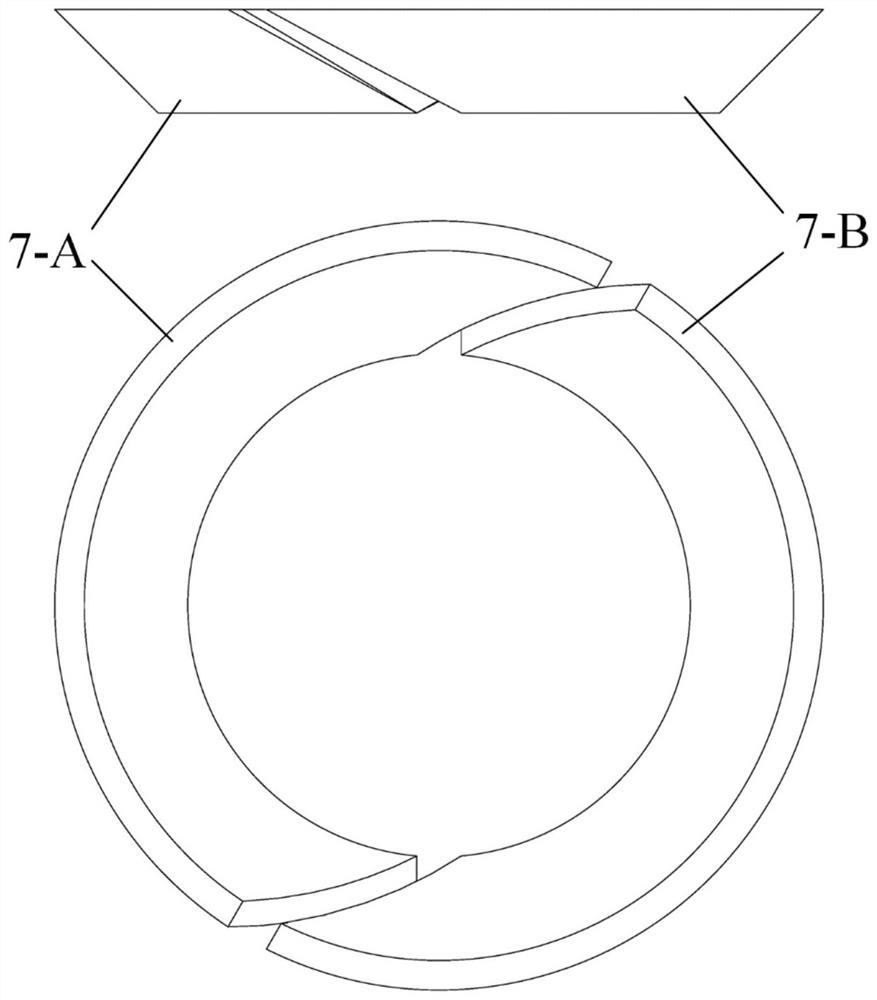

[0033] like figure 1 and figure 2 As shown, the sensor proposed by the present invention includes a top layer 1 , a middle layer 2 and a bottom layer 3 , and the top layer 1 , the middle layer 2 and the bottom layer 3 are stacked and arranged from top to bottom. The sensor generally presents a cylindrical structure with a maximum diameter of 6mm and a height of 2.5mm.

[0034] The top layer 1 is mainly composed of a spherical boss 4, a top layer flexible substrate 5 and a top layer electrode 6 stacked in sequence from top to bottom. The top surface of the top layer flexible substrate 5 is closely attached to the bottom surface of the spherical boss 4, and the top layer The end surface of the flexible base 5 is provided with an annular protrusion, and the outer peripheral surface and the inner peripheral surface of the annular protrusion are both convex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com