Antiskid soft insulation shielding tube for hot-line work

A technology for live work and shielding pipes, which is applied to overhead lines/cable equipment, etc., can solve the problems of insulation shielding failure, prone to accidents, and sliding of shielding objects, so as to improve the sliding of linear materials, prevent insulation loss, and improve insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

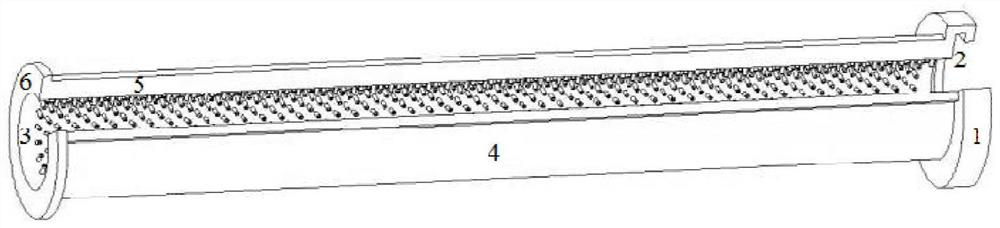

[0036] like figure 1 As shown, the purpose of this embodiment is to provide a non-slip soft insulating shielding pipe for live work, comprising at least one group of insulating shielding pipe bodies 4 connected end to end, and each group of insulating shielding pipe bodies 4 is included in the insulating shielding pipe body. 4 is an opening 5 arranged along the axial direction on the pipe wall of the insulating shielding pipe body. The inner wall of the insulating shielding pipe body is provided with anti-skid hairs 3. The structure of the outer protrusion 6 is matched.

[0037] One end of the insulating shielding pipe body 4 is connected to the pipe head 1, the pipe head 1 is annular, the inner surface of the pipe head 1 is connected to the outer surface of the insulating shielding pipe body 4, and the groove located in the inner circumferential direction of the pipe head 1 forms an inner recess. 2. The outer diameter of the pipe head 1 is larger than the outer diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com