Heating device

A technology of electric heating device and heating element, which is applied to electric heating device, coupling device, heating element, etc., can solve the problems of inconvenient connection, instability, influence on brazing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that the accompanying drawings disclose the invention in sufficient detail, if necessary, to help better define the invention. However, the present invention should not be limited to the embodiments disclosed in the specification.

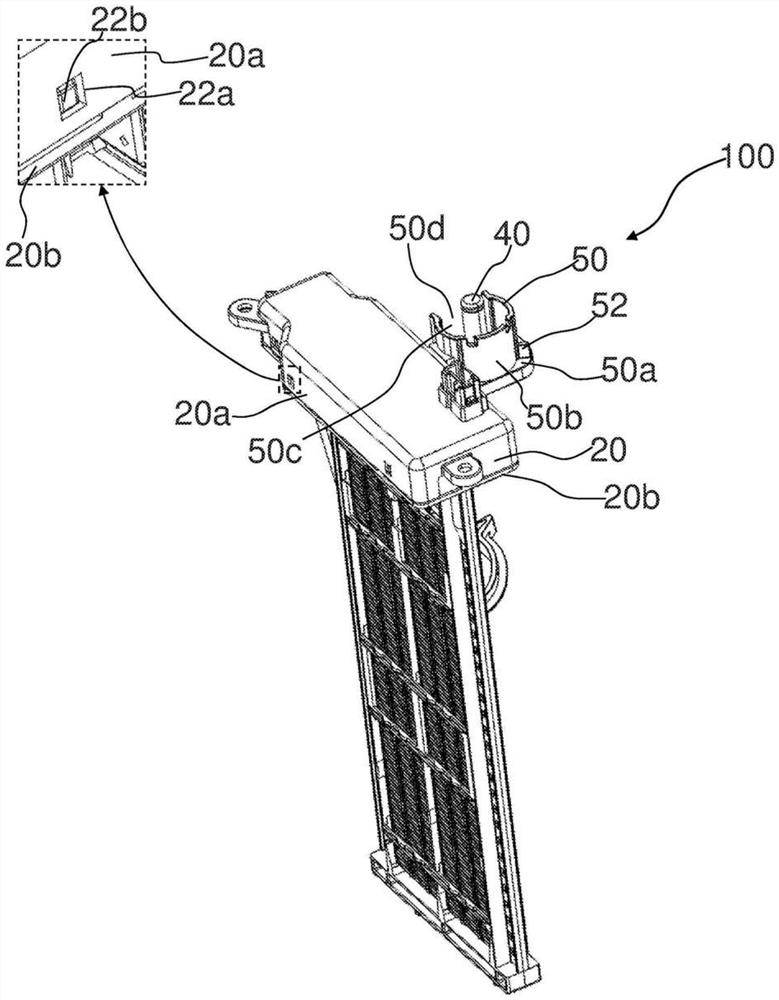

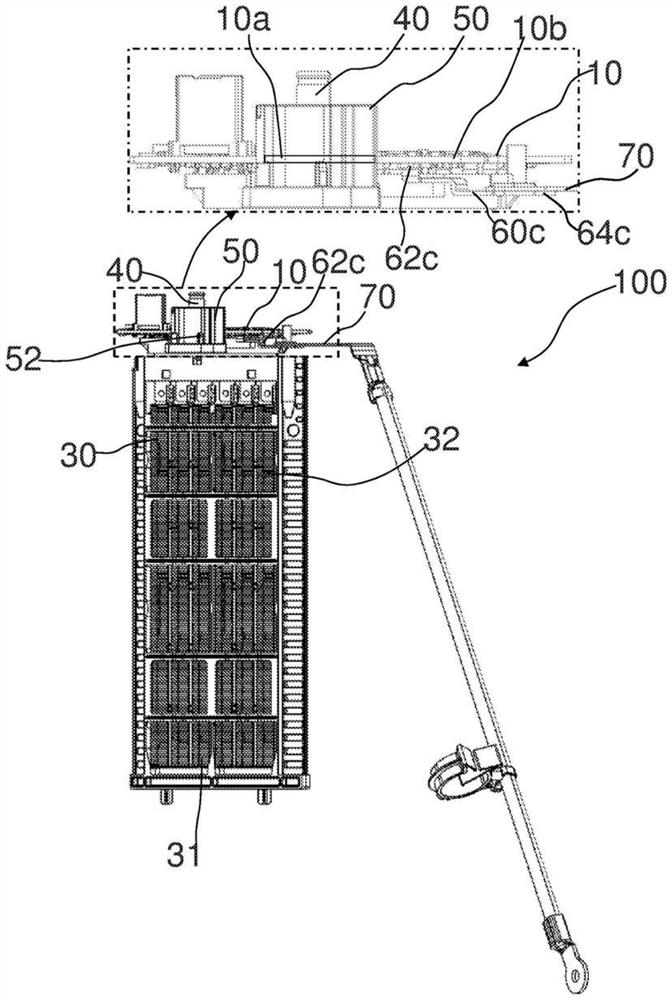

[0035] The present invention envisages a printed circuit board (PCB) controlled heating device, hereinafter, simply referred to as a heating device. The heating device includes a printed circuit board (PCB) (hereinafter simply referred to as "PCB"), at least one heating element, terminal pins, a terminal plate, and a plurality of bus bars. At least a portion of the PCB extends from a printed circuit board (PCB) housing, hereinafter simply referred to as a "PCB housing". The plurality of bus bars form a connection between the terminal pin and the terminal plate through the at least one heating element. Each bus bar includes at least one first terminal connected to a printed circuit board (PCB) disposed within the PCB hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com