Ag-MOF composite chitosan-based film as well as preparation method and application thereof

A chitosan and film technology, applied in the field of AgMOF composite chitosan-based film and its preparation, can solve the problems of non-degradability and lack of functionality, hinder the wide application of plastic films, etc., and achieve good air permeability, sterilization, The effect of good sustained release antibacterial properties and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

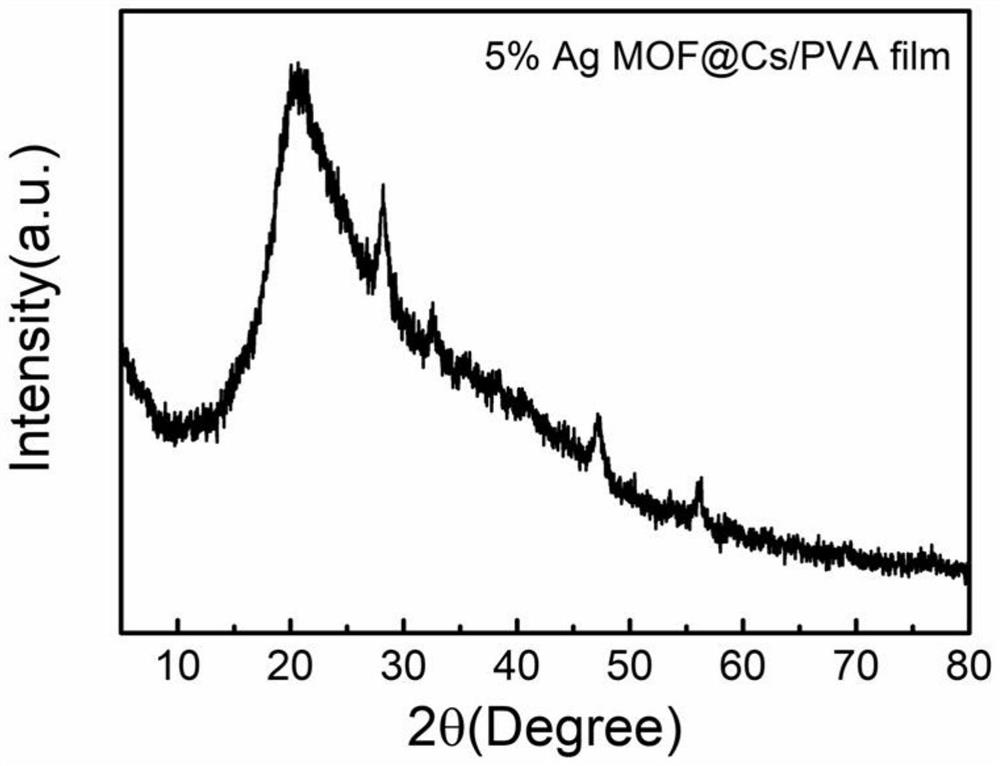

Image

Examples

Embodiment 1

[0059] A preparation method of Ag MOF composite chitosan-based film, specifically comprising the following steps:

[0060] (1) 60 mg of silver acetate AgC 2 H 3 O 2 Dissolved in 20ml of deionized water and mixed to form a silver acetate solution, 20mg of 2-aminoterephthalic acid C 8 H 7 NO 4 Dissolved in 20ml of absolute ethanol and mixed evenly to form a 2-aminoterephthalic acid solution, the two solutions were quickly mixed and left to stand for 48h, and then ultrasonically dispersed for 4h at an ultrasonic frequency of 25kHz, followed by a rotating speed of 10000r / min. After centrifugation for 15 min, the product in the centrifuge tube was washed with absolute ethanol, and the centrifugation washing operation was repeated 3 times. After drying in a vacuum drying oven at a drying temperature of 60 °C for 24 h, the product was taken out as Ag MOF.

[0061] (2) Add 2g of chitosan powder to 100ml of 2% acetic acid solution and stir to form a chitosan solution. The stirrin...

Embodiment 2

[0065] A preparation method of Ag MOF composite chitosan-based film is similar to Embodiment 1, and the difference is that it specifically includes the following steps:

[0066] (1) 60mgAgC 2 H 3 O 2 Dissolved in 20ml of deionized water and mixed to form a silver acetate solution, 20mg C 8 H 7 NO 4 Dissolved in 20ml of absolute ethanol and mixed evenly to form a 2-aminoterephthalic acid solution, the two solutions were quickly mixed and left to stand for 56h, then ultrasonically dispersed for 5h at an ultrasonic frequency of 25kHz, followed by a rotating speed of 8000r / min. After centrifugation for 20 min, the product in the centrifuge tube was washed with absolute ethanol, and the centrifugation washing operation was repeated 3 times. After drying for 36 h at a temperature of 60 °C in a vacuum drying oven, the product was taken out as Ag MOF.

[0067] (2) Add 2g of chitosan powder (degree of deacetylation ≥95%, viscosity 100-200mpa) into 100ml of 2% acetic acid solution...

Embodiment 3

[0071] A preparation method of Ag MOF composite chitosan-based film is similar to Embodiment 1, and the difference is that it specifically includes the following steps:

[0072] (1) 60mgAgC 2 H 3 O 2 Dissolved in 20ml of deionized water and mixed to form a silver acetate solution, 20mg C 8 H 7 NO 4 Dissolved in 20ml of absolute ethanol and mixed uniformly to form a 2-aminoterephthalic acid solution, the two solutions were quickly mixed and left to stand for 72h, and then ultrasonically dispersed for 6h at an ultrasonic frequency of 25kHz, followed by a rotating speed of 10000r / min. After 20 min of centrifugation, the product in the centrifuge tube was washed with absolute ethanol, and the centrifugation and washing operation was repeated 5 times. After drying at 60 °C for 48 h in a vacuum drying oven, the product was taken out as Ag MOF.

[0073] (2) Add 2g of chitosan powder to 100ml of 2% acetic acid solution and stir evenly to form a chitosan solution (stirring speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com