Handheld laser welding device

A laser welding and laser welding machine technology, applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of long welding substrate size, easy leakage at joints, and poor appearance of weld seams, so as to achieve beautiful weld seams and low cost Low, good welding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]Selected embodiments of the present invention will now be described with reference to the specification. The accompanying descriptions of the embodiments of the present invention by those skilled in the art based on the present disclosure are merely exemplary and are not intended to limit the solutions of the present invention.

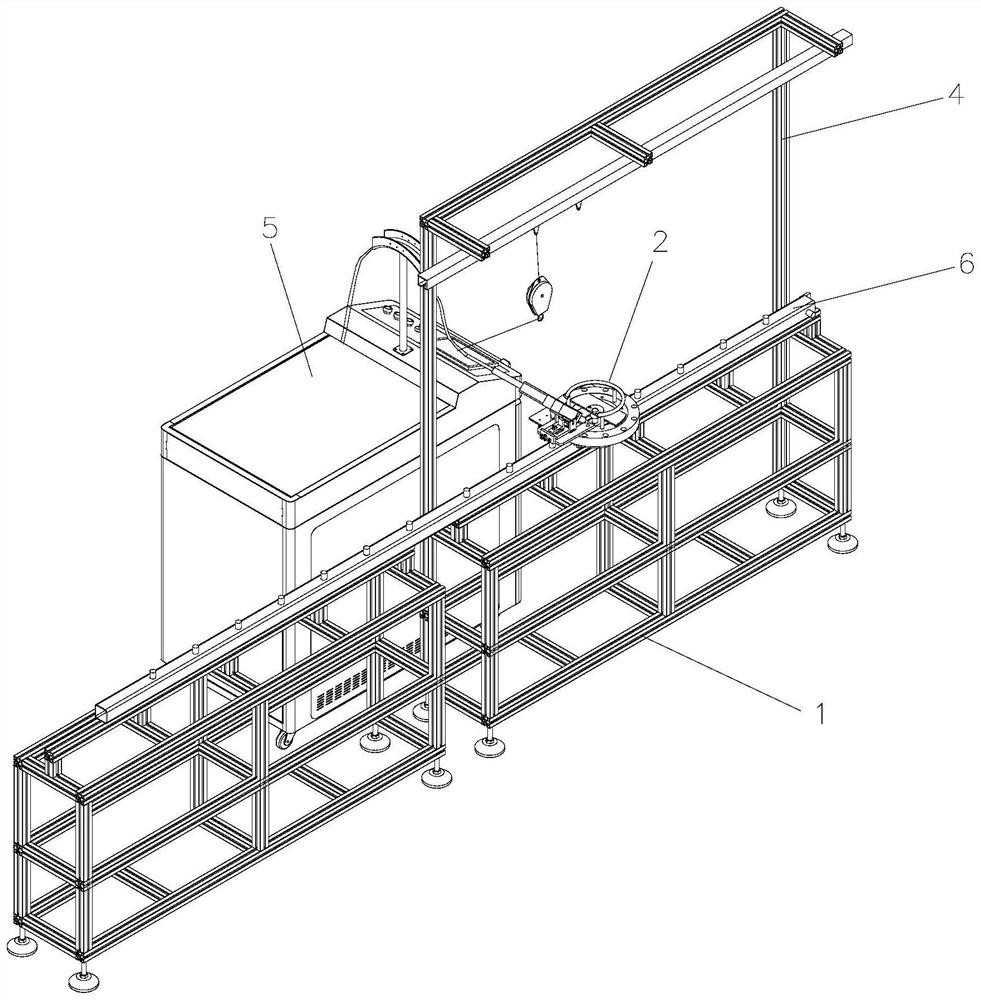

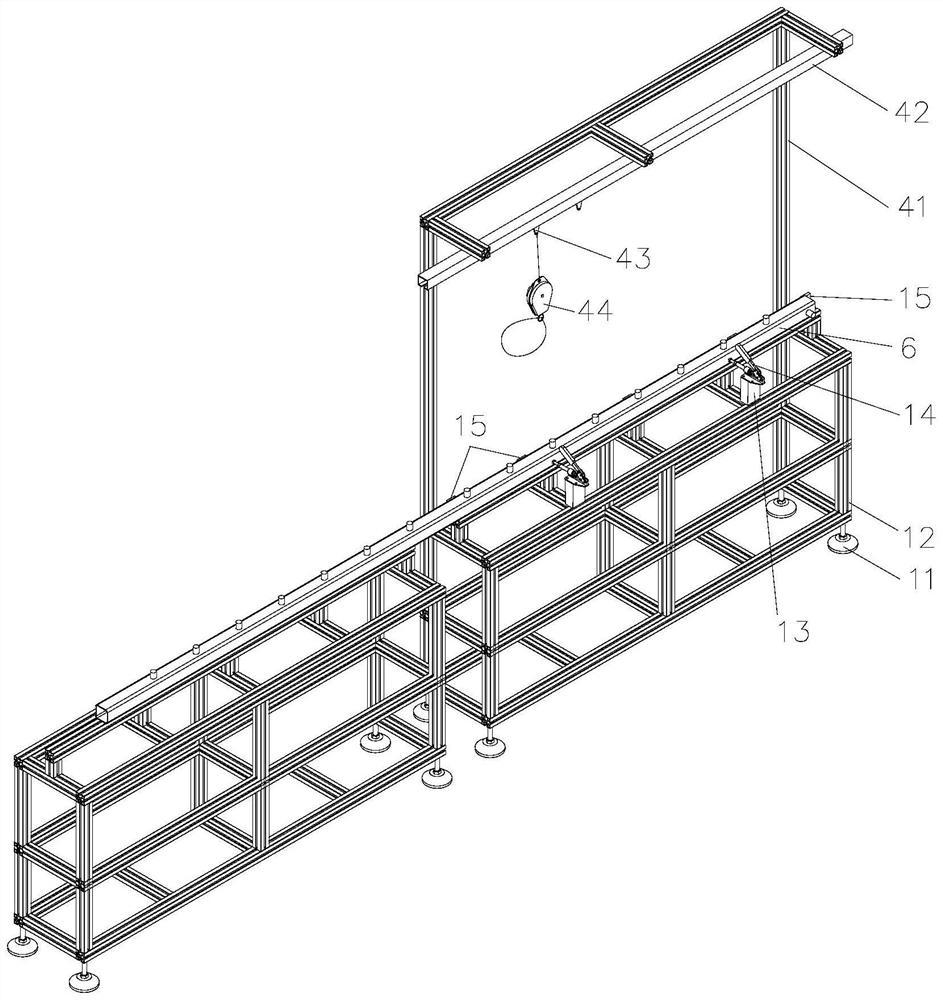

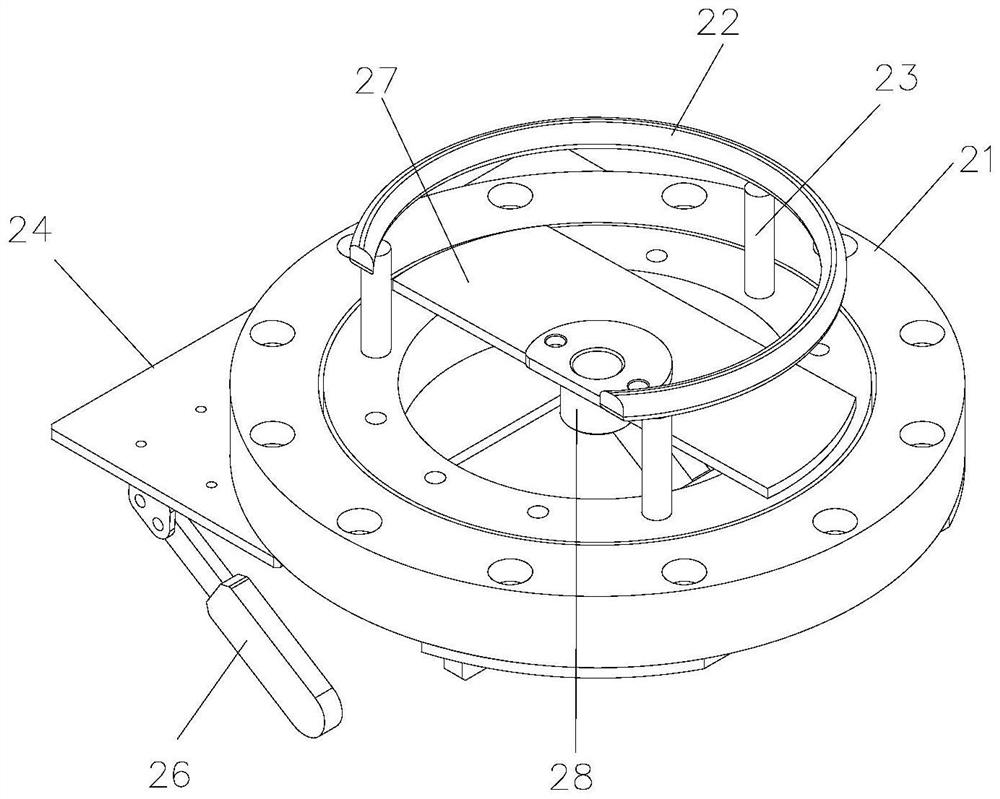

[0047] see attached figure 1 , attached Figure 10 and attached Figure 11 The hand-held laser welding device in an embodiment of the present invention includes a workpiece placing table 1, a positioning and rotating mechanism 2, an angle adjustment mechanism 3 and a hand-held laser welding machine 5, and the workpiece placing table 1 is used to place the workpiece 6 to be welded. The angle adjustment mechanism 3 is fixed on the top of the positioning and rotating mechanism 2, the hand-held laser welding machine 5 is arranged on one side of the workpiece placing table 1, and the hand-held laser welding machine 5 includes a laser 52, a transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com