Method for extracting and purifying sclareol from sclareol fermentation liquor

A technology of sclareol and fermentation liquid, applied in the separation/purification of hydroxyl compounds, organic chemistry, etc., to achieve the effect of simple operation, less process steps, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

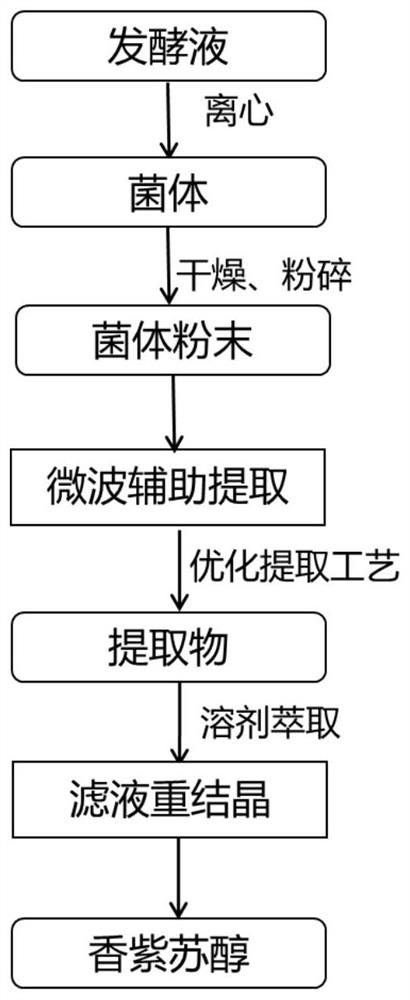

Method used

Image

Examples

Embodiment 1

[0024] 5g of dried bacterial powder was placed in 75mL of petroleum ether, extracted by microwave at 60°C for 10min, filtered with a suction filtration device, the filtrate was collected, and the filtrate was concentrated to obtain 0.74g of extract, with an extraction rate of 14.80%.

Embodiment 2

[0026] 5g of dried bacterial cell powder was placed in 75mL of n-hexane, extracted by microwave at 60°C for 10min, filtered with a suction filtration device, the filtrate was collected, and the filtrate was concentrated to obtain 0.67g of extract, with an extraction rate of 13.40%.

Embodiment 3

[0028] Put 5g of dry bacterial powder in 25mL of absolute ethanol, extract by microwave at 60°C for 10min, filter with suction filtration device, collect the filtrate, and concentrate the filtrate to obtain 0.78g of extract, with an extraction rate of 15.60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com