Plastic master batch processing and preparing system

A preparation system, plastic masterbatch technology, applied in the direction of coating, etc., can solve the problems of fan energy can not be fully utilized, energy waste, etc., to achieve the effect of reducing energy loss and waste, reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

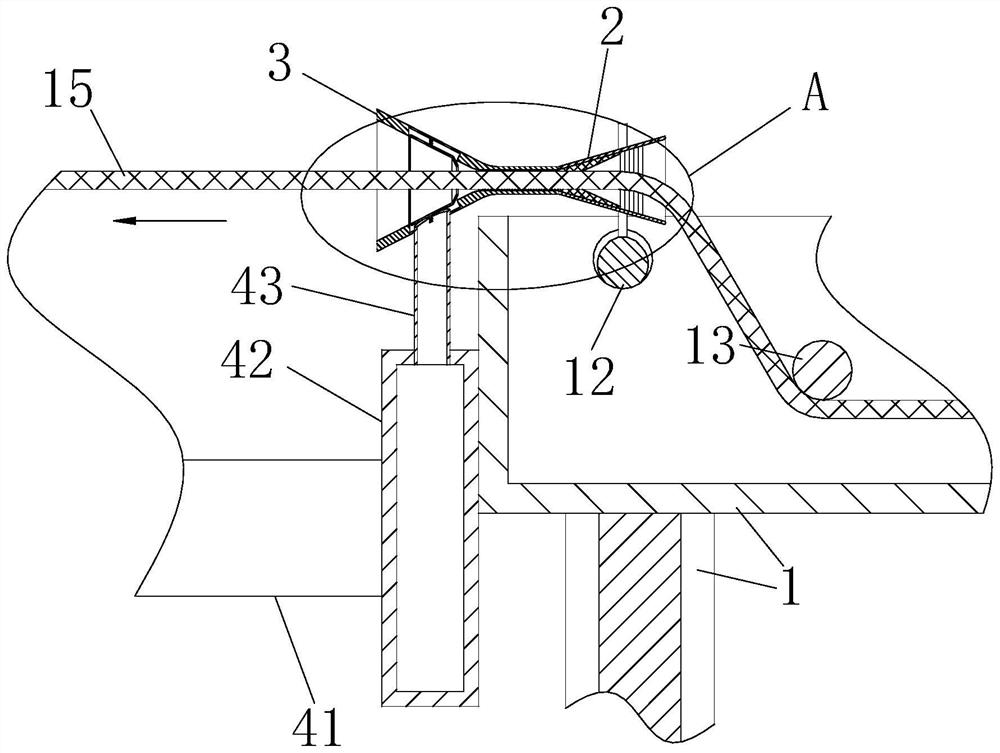

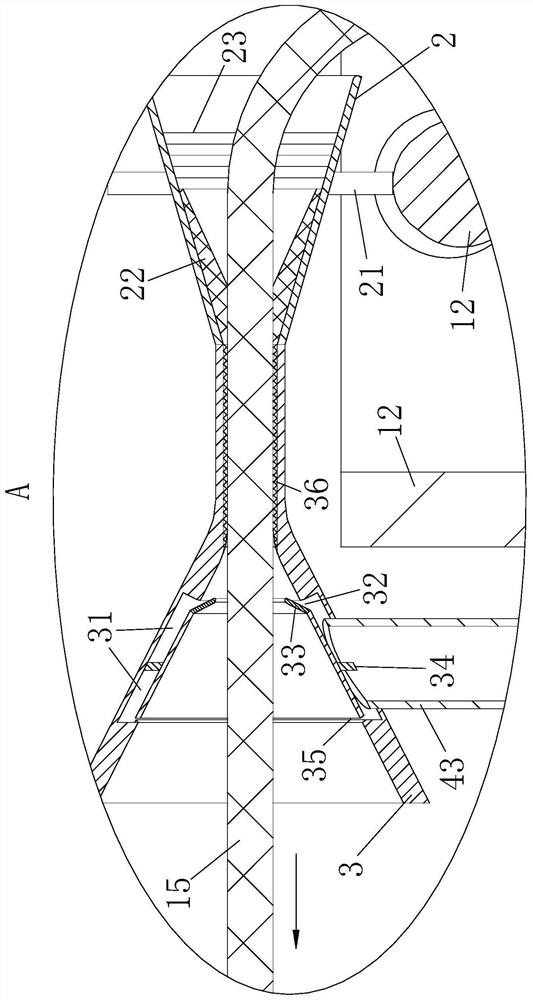

[0035] As an embodiment of the present invention, the dehumidification mechanism includes: a conical ring 2, the conical ring 2 is evenly rotatably mounted on the side wall of the body 1 and located above the worm 12, the conical ring 2 The surface of the inner wall is fixedly connected with a sponge layer 22, and the sponge layer 22 is used to absorb the water droplets adhering to the surface of the wire material 15;

[0036] A worm wheel 21, the worm wheel 21 is sleeved and fixedly connected to the outer surface of the tapered ring 2, and the worm wheel 21 is designed to engage with the worm 12;

[0037] an air-drying piece, which is rotatably connected to the front end of the conical ring 2, and the air-drying piece is used to dry the moisture remaining on the outer surface of the wire material 15;

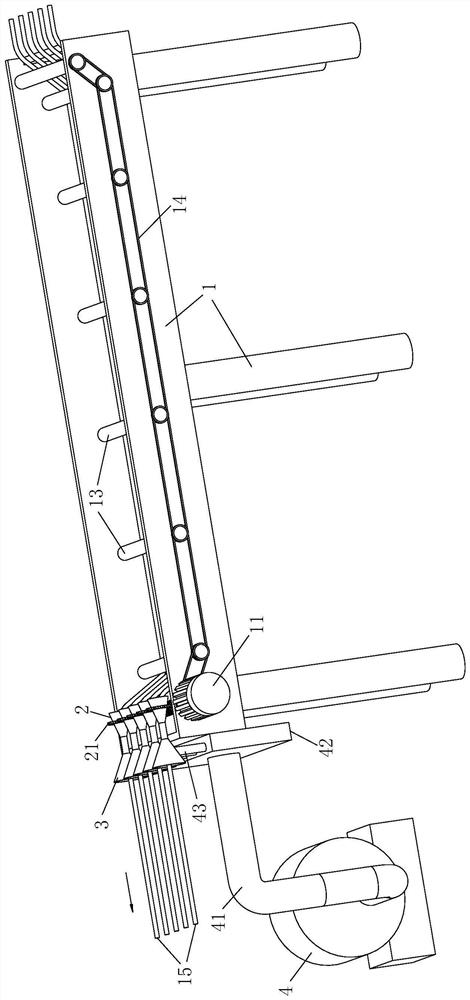

[0038] while working, such as figure 1 and figure 2As shown, since the uniformly arranged conical ring 2 is installed on the top of the worm 12, the wire 15 after the coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com