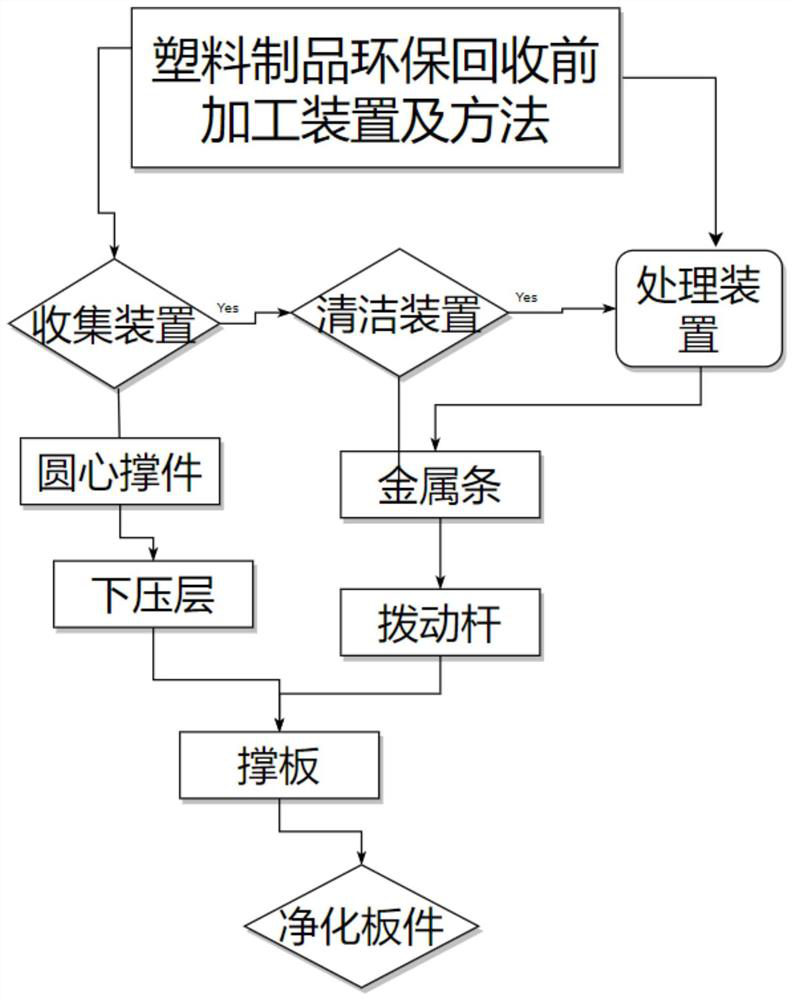

Processing device and processing method for plastic products before environment-friendly recycling

A pre-processing technology for plastic products, which is applied in the field of pre-processing devices for environmental protection recycling of plastic products, to achieve the effect of saving time, reducing cumbersome steps, and facilitating recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

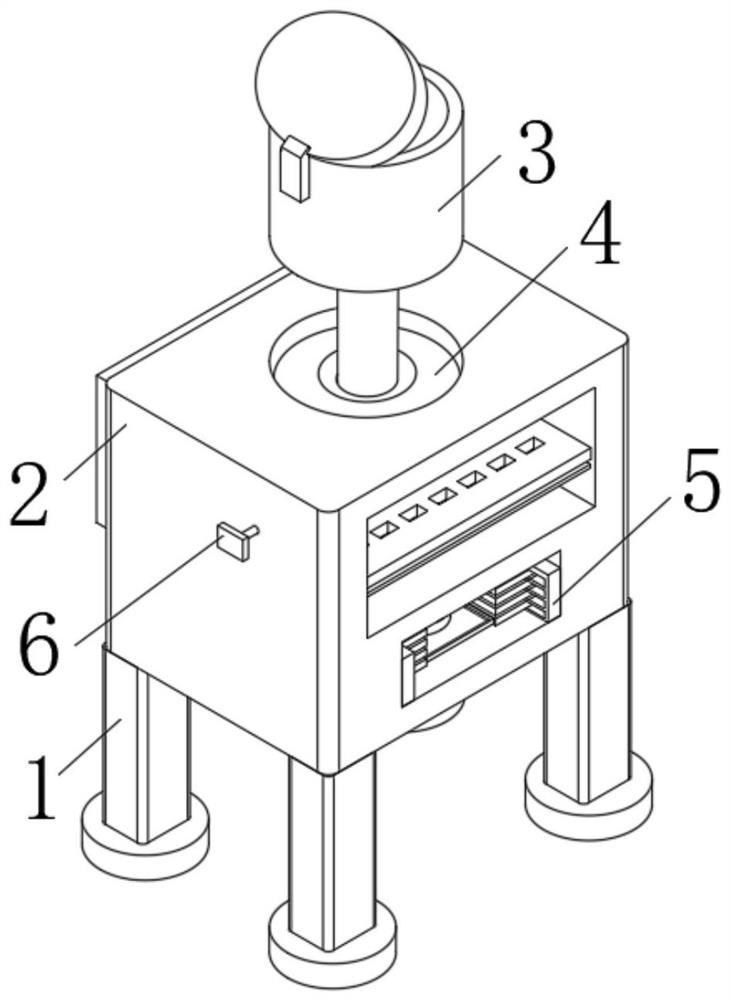

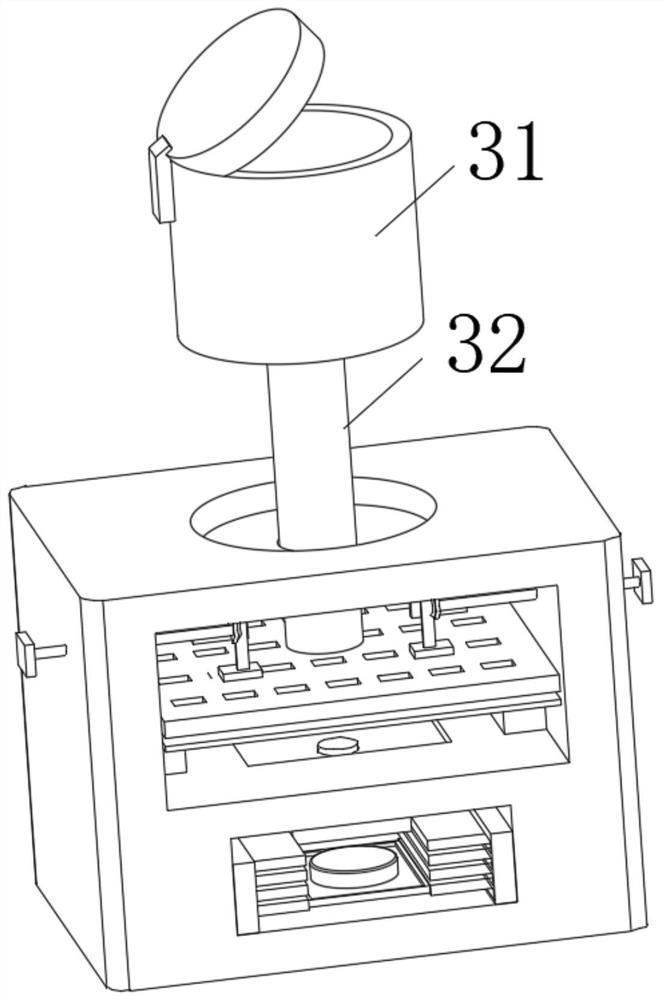

[0040] see Figure 2-Figure 7 , the present invention provides a kind of technical scheme:

[0041] A pre-processing device for environmental protection recycling of plastic products, comprising a base leg base 1, the upper surface of the base leg base 1 is provided with a metal casing 2, and the upper surface of the base leg base 1 is fixedly connected with the lower surface of the metal casing 2, and the metal casing 2 The middle of the top is provided with a processing device 3, through the setting of the processing device 3, some internal wastes can be effectively sorted out, which has the effect of automatic rectification, achieves the effect of automatic cleaning, and realizes the purpose of automatic environmental protection. The middle part is movably connected with the outer surface of the processing device 3,

[0042] The processing device 3 includes a metal cylinder 31, the lower surface of the metal cylinder 31 is provided with a center plate layer 32, and the low...

Embodiment 2

[0049] see figure 2 Figure 10 The invention provides a technical solution: on the basis of the first embodiment, the outer surface of the processing device 3 is provided with a transparent plate member 4, and the outer surface of the processing device 3 is movably connected with the inner surface of the transparent plate member 4, and the inner surface of the metal casing 2 is movably connected. The bottom of the cavity is provided with a collection device 5, and the bottom of the inner cavity of the metal shell 2 is movably connected to the outer surface of the collection device 5. The setting of the collection device 5 ensures that the interior has a certain processing effect and ensures the reasonable recovery of waste. In favor of secondary processing, the middle part of the inner cavity of the metal shell 2 is provided with a start rod 6, and the middle part of the inner cavity of the metal shell 2 is movably connected with the outer surface of the start rod 6;

[0050...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com