Semi-automatic wire binding device for bunching test

A test, semi-automatic technology, applied in the direction of cable installation, electrical components, cable installation devices, etc., can solve time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

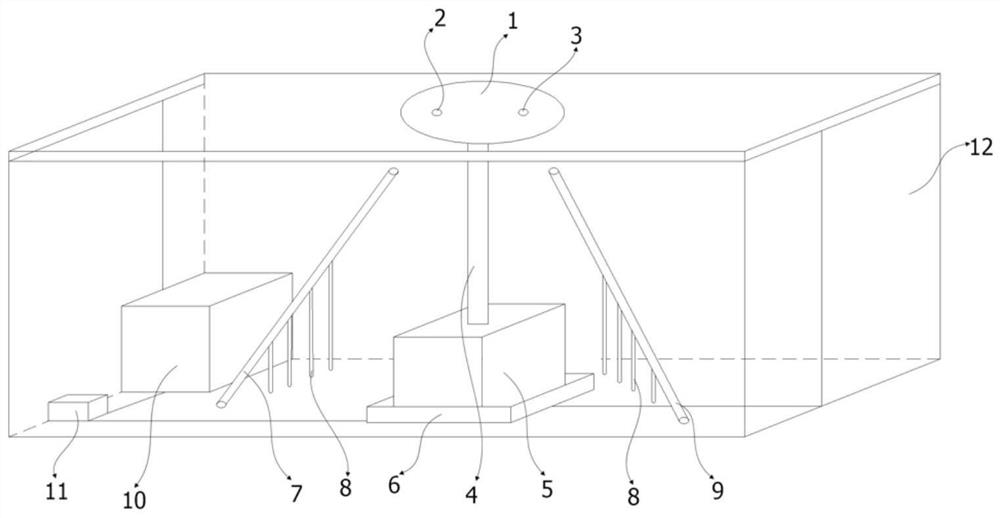

[0013] like figure 1 As shown in the figure, the semi-automatic wire binding device for bundling test includes a casing 12, and a transmission rod 4, a rotary power mechanism 5, a wire inlet guide 7, and a wire outlet guide 8 are installed in the casing 12. A transmission wheel 1 is installed, and the transmission wheel 1 is installed on the rotary power mechanism 5 through the transmission rod 4 , and the rotary power mechanism 5 has a shock-absorbing pad 6 under the rotary power mechanism 5 . Specifically, the rotary power mechanism 5 is a motor. In order to facilitate binding, the transmission wheel 1 is located outside the casing 12 .

[0014] A battery box 10 is also installed in the casing 12 , and the battery box 10 is connected to the rotary power mechanism 5 through a switch 11 to realize switch control.

[0015] The transmission wheel 1 has a wire inlet hole 2 and a wire outlet hole 3. Below the transmission wheel 1, the wire inlet hole 2 is provided with a wire in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com