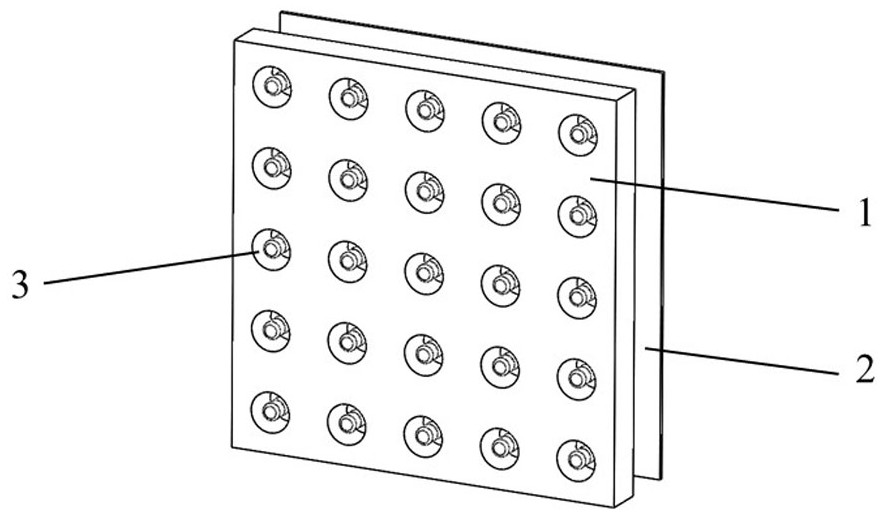

Micro-perforated plate sound absorber with axial periodic rough surface annular micropores

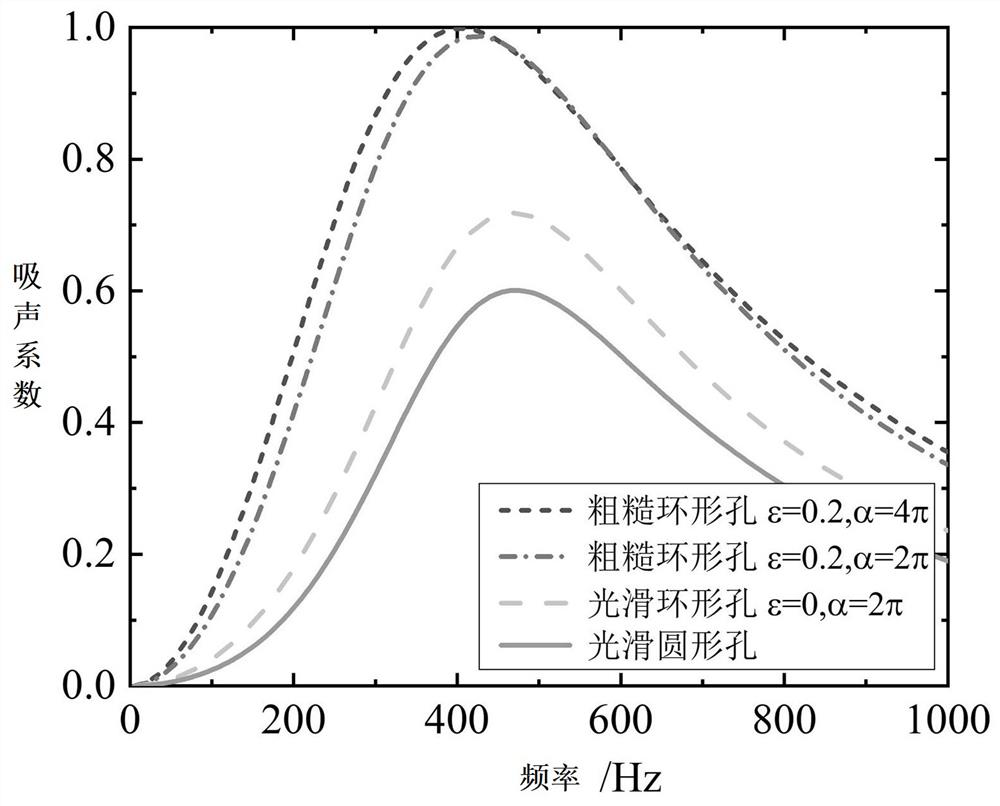

A rough surface and micro-perforated plate technology, which is applied in the direction of sound-generating devices, instruments, building components, etc., can solve the problems that affect the application performance of micro-perforated plates, the difficulty of adjusting the sound absorption frequency band, and the difficulty of improving sound absorption performance, etc., to achieve light weight, The effect of widening the bandwidth and improving the sound absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0034] Examples of materials:

[0035] Air: characterized by a density of 1.205kg / m 3 , the speed of sound is 343m / s.

[0036] Metal aluminum: characterized by a density of 2700kg / m 3 , Young's modulus is 69GPa, Poisson's ratio is 0.33.

[0037] Embodiment structure size:

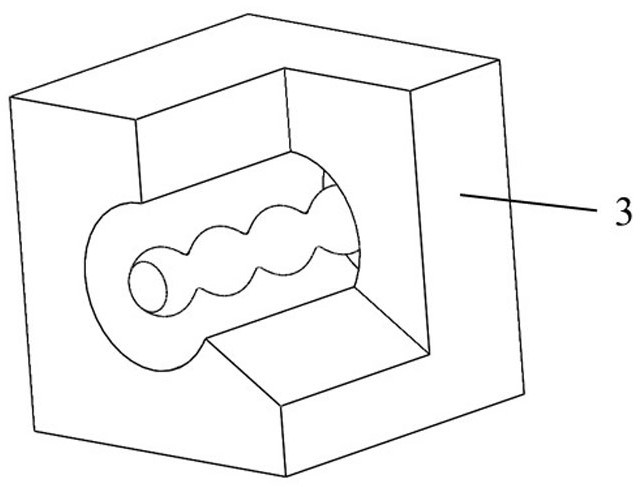

[0038] Micro-perforated panel 1 Thickness: t 1 =12mm, cavity thickness: t 2 = 100mm. The hydraulic radius of the inner wall of the annular sound-absorbing hole 3: r 0 =0.5mm, the radius of the outer wall of the annular sound-absorbing through hole 3: r 1 = 0.9 mm. The value range of the amplitude ε of the periodic rough surface is [0,0.2], and the value range of the wave number α of the periodic rough surface is [0,4π]. The perforation rate is 14%, and the cavity between the micro-perforated panel 1 and the rigid backing 2 is not filled with porous sound-absorbing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com