Portable container system and method for manufacturing same

A portable and container technology, which is applied in containers, rigid containers, and cigarette manufacturing, and can solve problems such as waste, stale cigarettes, and scatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

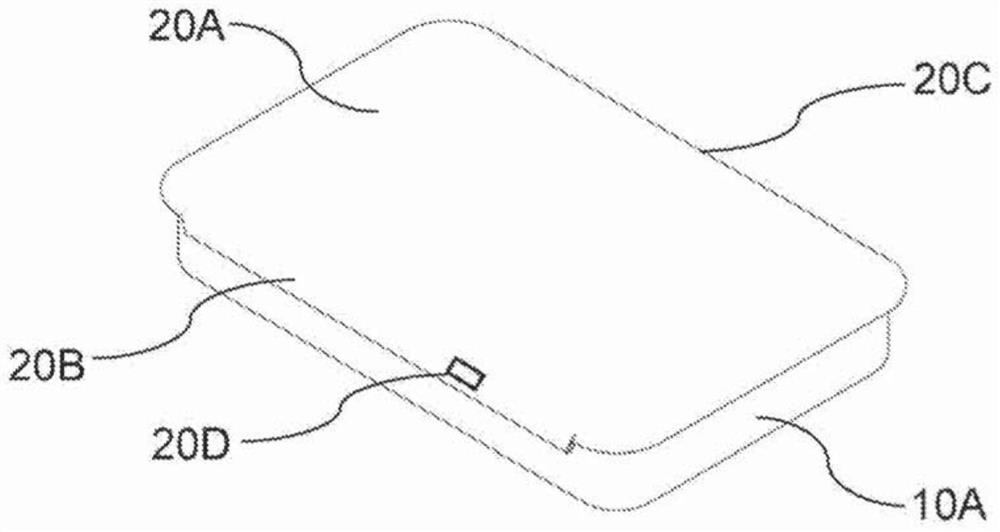

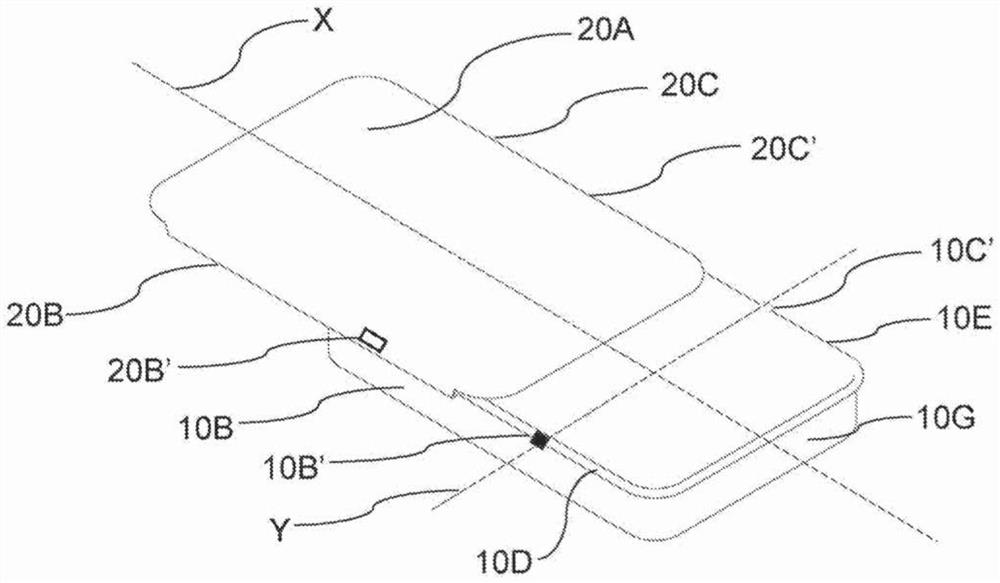

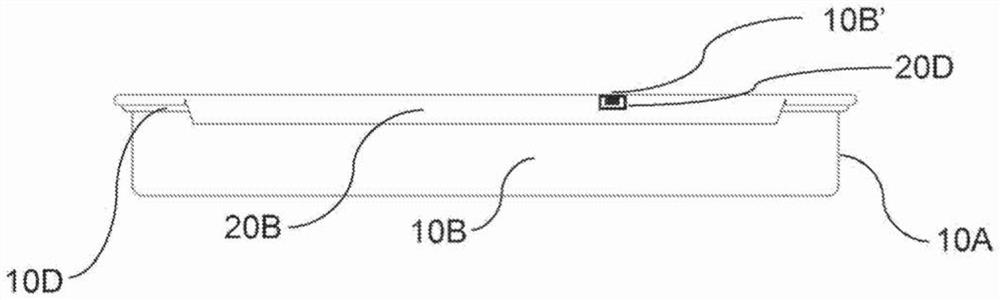

[0119] This article will now refer to Figures 1 to Figure 15 Preferred embodiments of the present invention are described. Embodiments include portable container systems such as may be used, for example, to store rolled cigarettes and the like, but are not necessarily limited to such items. In an embodiment of the invention to be described, the container system includes a portable and preferably pocket-sized rigid tin container 10A, 10B, 10C and an insertion storage tray configured to be inserted into the cavity of the rigid tin container 10A, 10B, 10C 30. The insertion tray 30 is configured to self-fix within the rigid tin container after insertion into the rigid tin container. The rigid tin containers 10A, 10B, 10C may preferably be formed of tin, although any other suitable rigid metal (eg, aluminum) or plastic material may be used.

[0120] In this embodiment, rigid tin containers 10A, 10B, 10C are first drawn, molded, pressed and / or stamped from sheet metal blanks into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com