Splicing sheet material

A net material and attachment technology, applied in the direction of transportation and packaging, chemical instruments and methods, layered products, etc., can solve the problem of reducing the strength of multi-layer pile fabric materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The systems and methods described herein can bypass landfill and repurpose materials by converting waste or excess fabric (eg, non-crimped fabric material) on-site into mid-grade products, which can improve material utilization, improve environmental Friendly and reduces the associated costs in the case of disposal of excess waste.

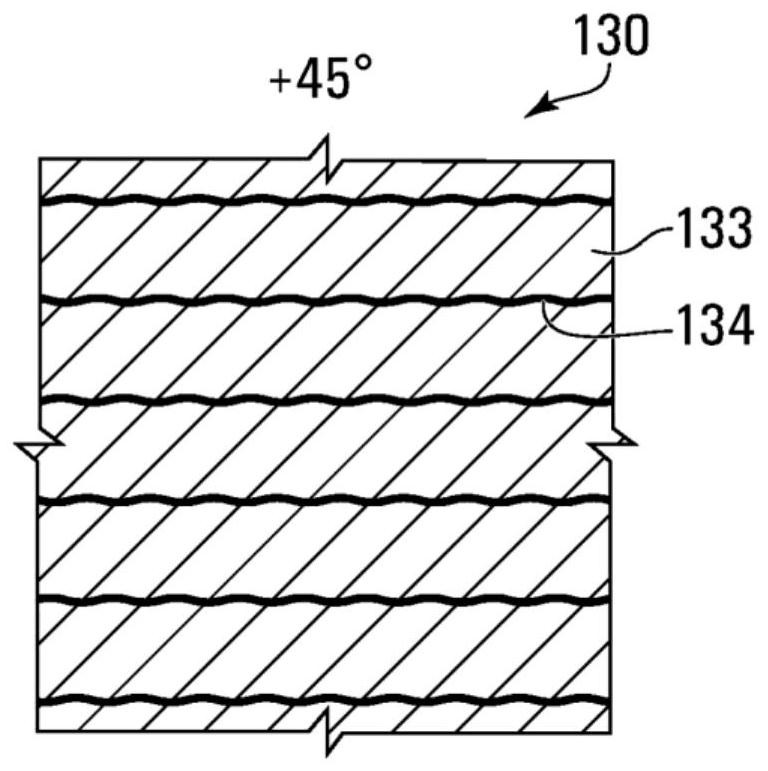

[0054] Fabrics such as waste non-crimped fabric materials can be formed as long-fiber discontinuous non-crimped fabric panel materials with conventional fiber orientations (eg, 0 / 90° fiber orientation and + / - 45° fiber orientation). As described herein, a non-crimp fabric panel material is formed from a non-crimp fabric panel attached to a carrier web.

[0055] Panel materials such as non-crimped fabric panel materials may exhibit sufficient structural properties, including sufficient tensile strength, to withstand cutting and laying.

[0056]Plies of panel material (eg, non-crimped fabric panel material) can be laid up and impregnated wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com