Method for estimating tunneling rock mass strength of TBM (Tunnel Boring Machine) and performing graded early warning

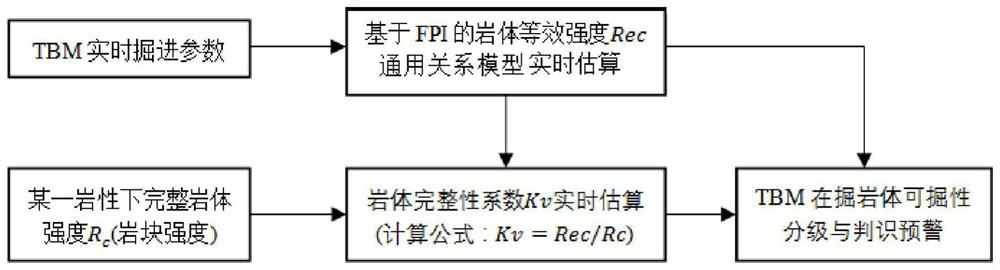

A technology for rock mass strength and rock excavation, which is applied in the field of TBM tunnel construction, can solve the problems that the rock strength measurement model is not suitable for jointed rock mass, and the tunnel surrounding rock classification method is not suitable for TBM construction, etc., and achieves easy online acquisition and classification indicators. Parameter simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

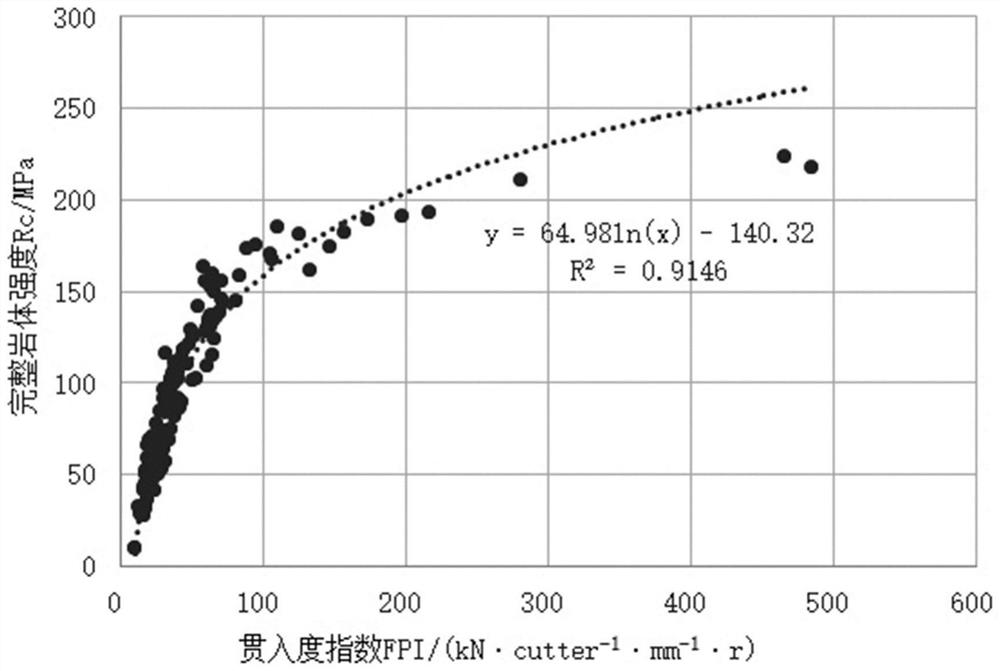

Method used

Image

Examples

example 1

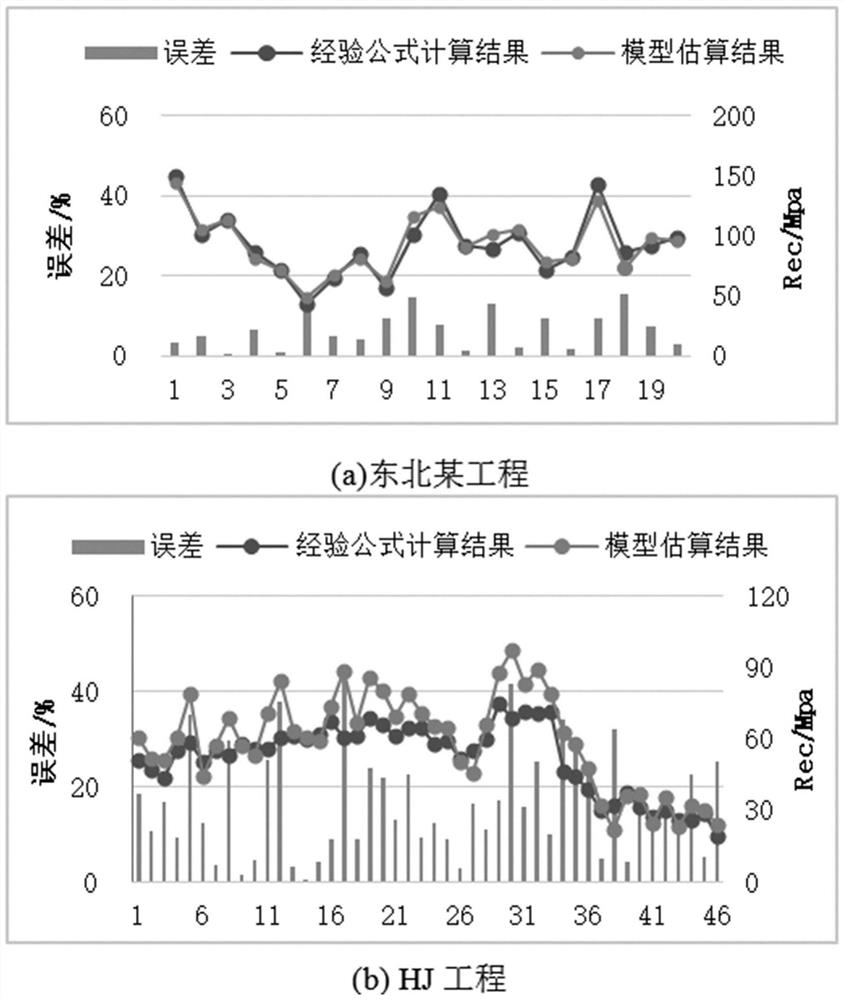

[0082] Example 1: Stake section of a water diversion project of a reservoir in Zhejiang: 15+916~15+716(200m)

[0083] Lithology: Breccia fused tuff

[0084] Average compressive strength: 145MPa

[0085] On-site classification of surrounding rock in the tunnel section: Class II

[0086] Actual rock mass conditions: joints and fissures are not well developed on the excavation surface, the structural surface is mainly closed, and the flatness of the cave wall is good; the surrounding rock integrity is good; there is no water seepage; The surrounding rock of pile numbers 15+870~15+760 and 15+732~15+726 is partially broken.

[0087] Supporting method: no support; mesh support at local broken parts, plain sprayed concrete.

[0088] from Figure 4 It can be seen that the thrust is basically maintained at 7000kN, the penetration range is 0.5~8mm / r, and the change is large. The equivalent strength of the rock mass estimated based on formula (3) ranges from 50MPa to 250MPa, with an...

example 2

[0091] Stake section of a water diversion project in Guangzhou: 23+847~23+716 (131m)

[0092] Lithology: Granite

[0093] Average rock strength: 118MPa

[0094] On-site classification of surrounding rock in the tunnel section:

[0095] 23+847~23+765(82m): Class II

[0096] 23+765~23+743(22m): Class III

[0097] 23+743~23+716(27m): Class II

[0098] Actual rock mass conditions:

[0099] 23+847~23+765 and 23+743~23+716: rock is hard; joints and fissures are not developed on the excavation face, and the rock mass is complete to relatively complete; the surrounding rock is basically stable; the excavation face is dry.

[0100] 23+765~23+743: Hard rock; well developed joints and fissures on the excavation face, poor integrity of the rock mass; weakly differentiated surrounding rock, poor local stability; a small amount of water dripping locally.

[0101] Support method:

[0102] 23+847~23+765, 23+743~23+716: not supported

[0103] 23+765~23+743: System bolts with reinforcem...

example 3

[0105] Example 3: Stake section of a TBM water diversion project in Xinjiang: 51+887~51+700 (187m)

[0106] Lithology: tuffaceous sandstone

[0107] Average rock strength: 100MPa

[0108] On-site classification of surrounding rock in the tunnel section: Class II

[0109] Actual rock mass conditions: cracks on the excavation face are not developed and dry; the rock mass is complete

[0110] Support method: no support.

[0111] Select the complete hole section data of class II for analysis, from Image 6 It can be seen that the thrust of this tunnel section is basically maintained at 17000kN, and the average penetration is 8.58mm / r. The calculation shows that the FPI range is 20-50, and the TBM tunneling performance is good. The equivalent strength and integrity coefficient of the rock mass obtained by using the model described in formula (1) in the present invention are relatively high, and the equivalent strength of the rock mass is basically maintained at 50-130 MPa, with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com