Automatic stripping equipment for thin film roll material

An automatic peeling and film technology, which is applied in plastic recycling, packaging, transportation and packaging, etc., can solve the problems of position deviation and poor stability, and achieve the effect of less space, low cost and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

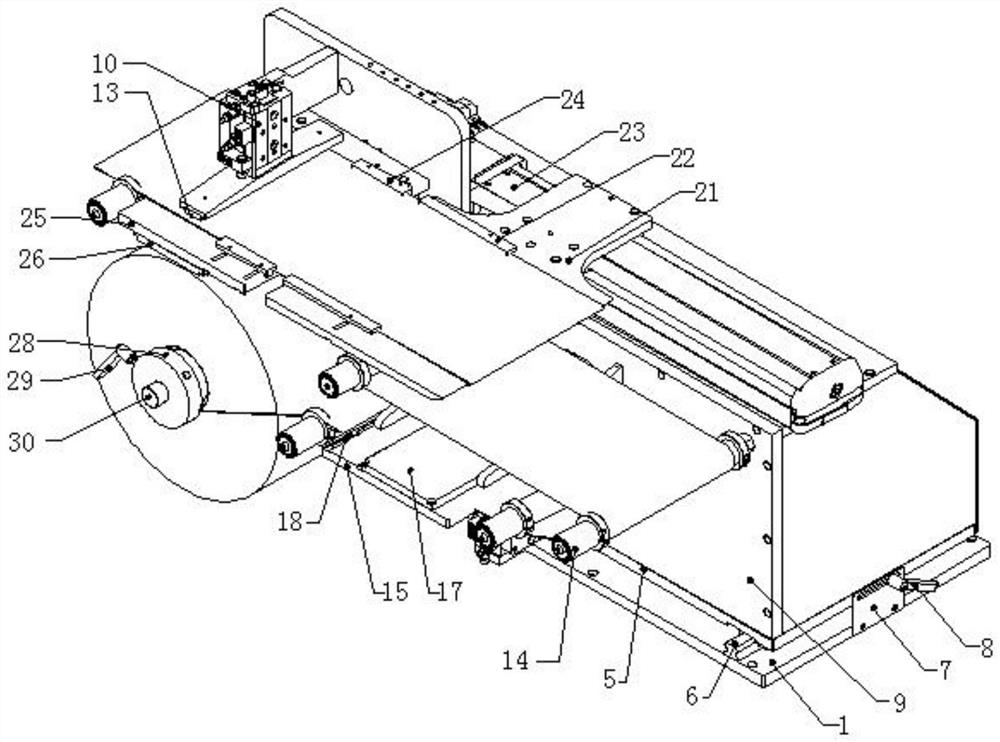

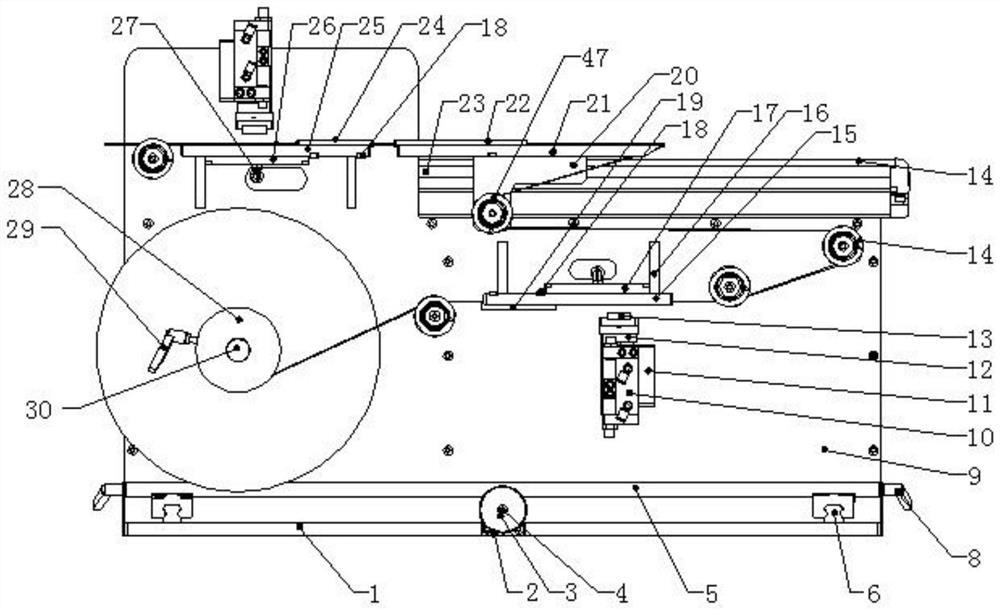

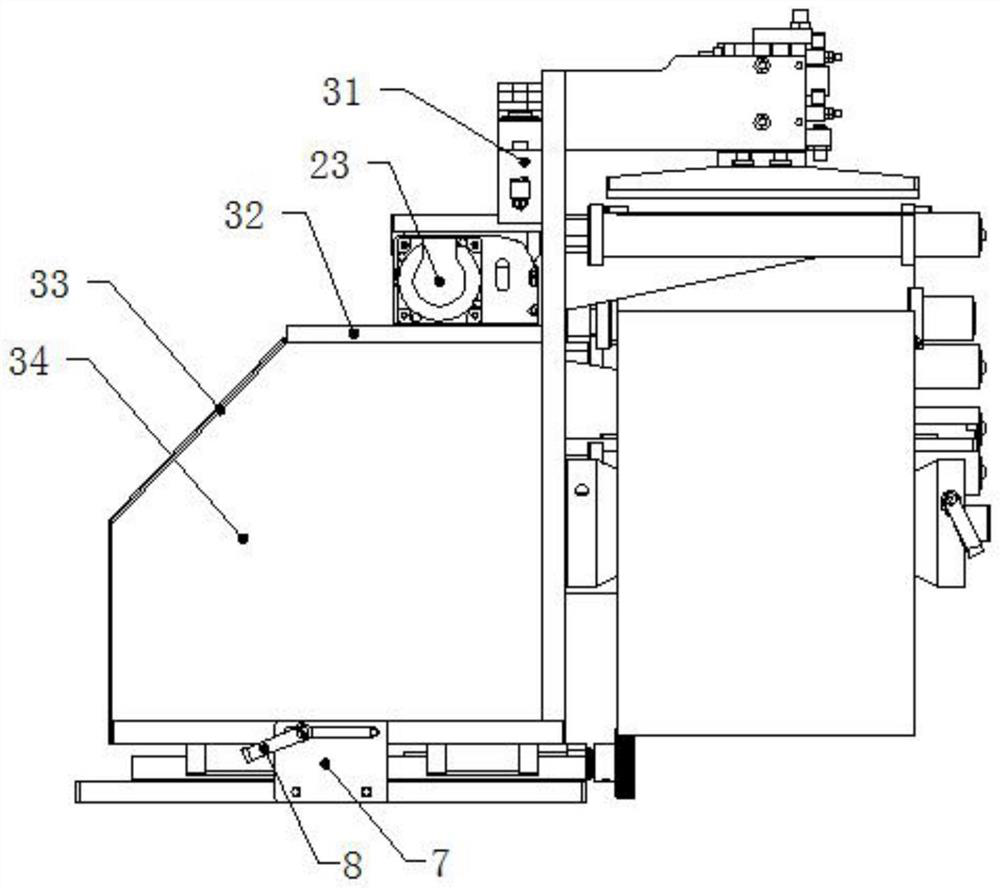

[0030] as Figure 1-5 As shown, a film coil automatic stripping device, comprising a linear rail mounting plate 1, mounting base plate 5 and main mounting plate 9, the mounting base plate 5 can be sliding through the sliding assembly can be sliding connection above the linear rail mounting plate 1, the linear rail mounting plate 1 and the left and right sides of the mounting base plate 5 are provided with a positioning adjustment plate 7 and a first fastening handle 8, the adjustment plate 7 is fixed by a screw connection to the linear rail mounting plate 1, The connecting end of the first tightening handle 8 runs through the lumbar hole of the adjustment plate 7 after being connected to the mounting base plate 5, and the tightening limit is carried out by rotating the first tightening handle 8;

[0031]The main mounting plate 9 is vertically connected to the mounting base plate 5, the main mounting plate 9 and the mounting base plate 5 are connected in the common vertical directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com