Auxiliary frame for bending steel bars at top of rotary excavating pile

A technology of rotary digging piles and auxiliary frames, applied in the field of steel bar bending auxiliary frames, which can solve the problems of complex operation and large volume, and achieve the effect of simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

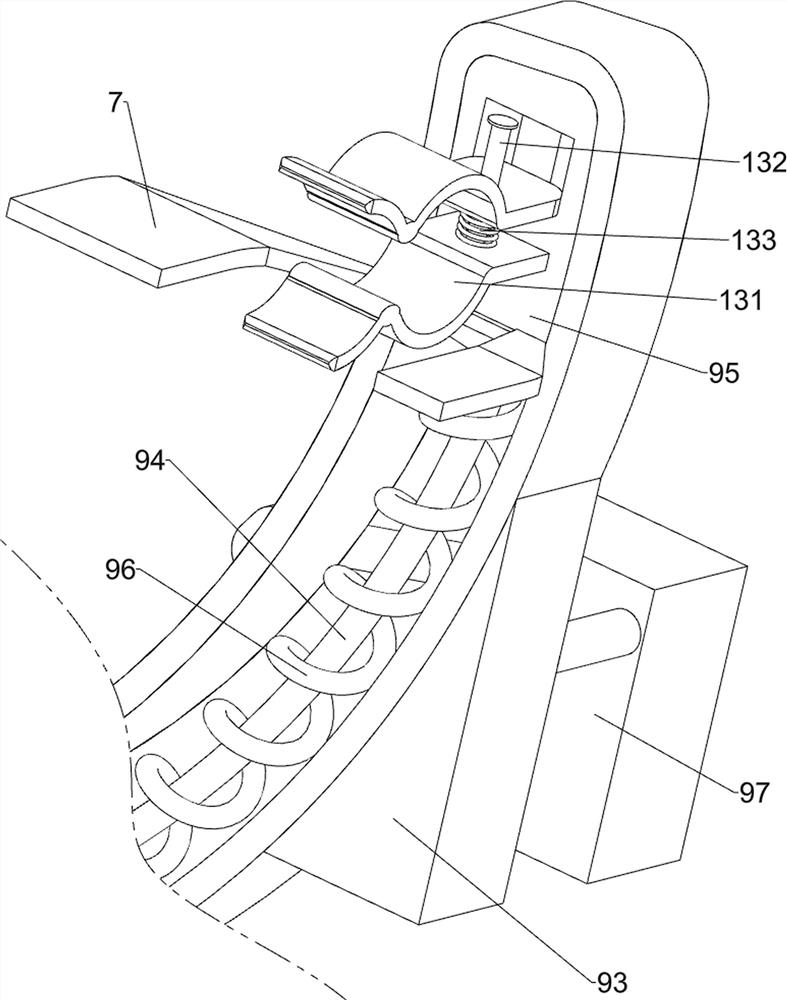

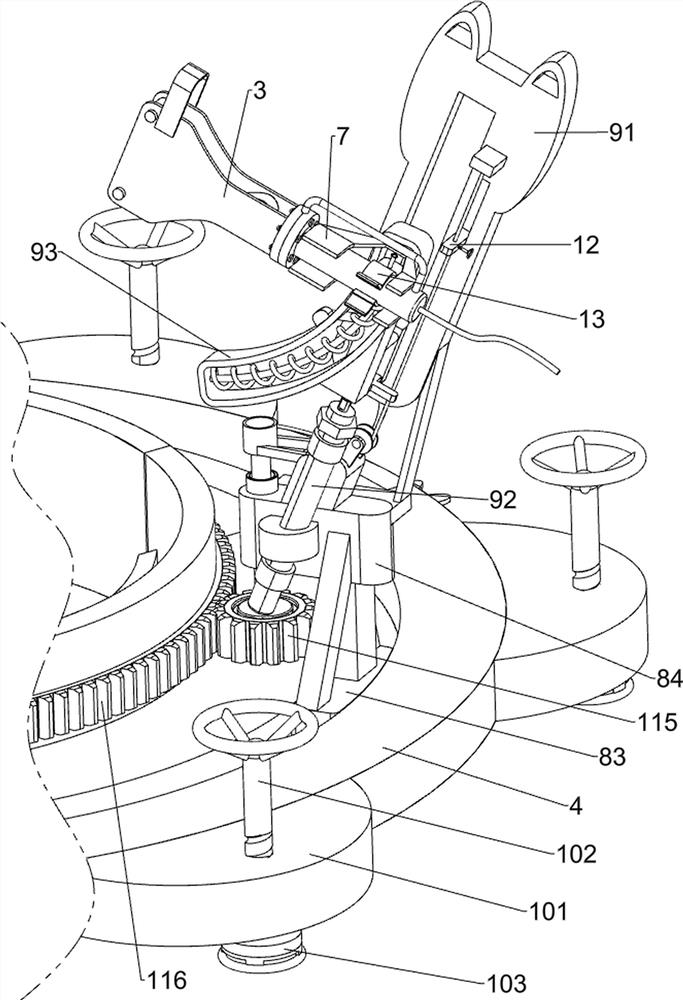

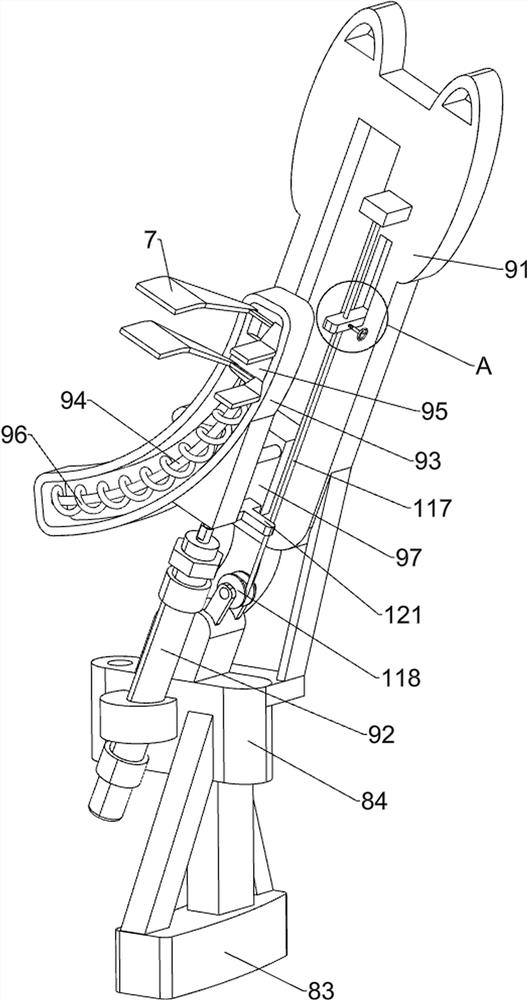

[0030] An auxiliary frame for bending and bending of steel bars at the top of a rotary excavation pile, refer to Figure 1-Figure 4 , including a first bottom plate 4, a second bottom plate 5, a contact plate 6, a limit plate 7, a moving mechanism 8 and an auxiliary mechanism 9, the first bottom plate 4 is located on the front side of the second bottom plate 5, and the rear side of the first bottom plate 4 is connected to the The front sides of the two bottom plates 5 are in contact with each other, the middle part of the rear side of the first bottom plate 4 and the middle part of the front side of the second bottom plate 5 are welded with a contact plate 6 , the first bottom plate 4 is provided with a moving mechanism 8 , and the moving mechanism 8 is provided with an auxiliary mechanism 9. Two limit plates 7 are provided on the auxiliary mechanism 9 , and the limit plates 7 can limit the support of the press brake 3 .

[0031] refer to Figure 1-Figure 3 , the moving mecha...

Embodiment 2

[0035] On the basis of Example 1, refer to Figure 1-Figure 3 , also includes a balance mechanism 10, the balance mechanism 10 includes a connecting plate 101, an adjustment screw 102 and an adjustment block 103, and three connecting plates 101 are welded at intervals between the outer lower part of the first base plate 4 and the outer lower part of the second base plate 5. The number of the plates 101 is six, the connecting plate 101 is provided with an adjusting screw 102 in a threaded manner, the upper part of the adjusting screw 102 is provided with a handle, and the lower part of the adjusting screw 102 is provided with an adjusting block 103 in a rotating manner, and the adjusting block 103 can move downward. Jack up the whole device to achieve the purpose of adjusting the angle.

[0036] When the contact plates 6 are all in contact with the rotary excavation pile 1, people can see whether the first bottom plate 4 and the second bottom plate 5 are parallel to the rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com