Tool for bearing large-size soft materials and using method thereof

A technology of large size and material, applied in the field of die-cutting and receiving structures, it can solve the problems of arching and bending, and the inability to transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

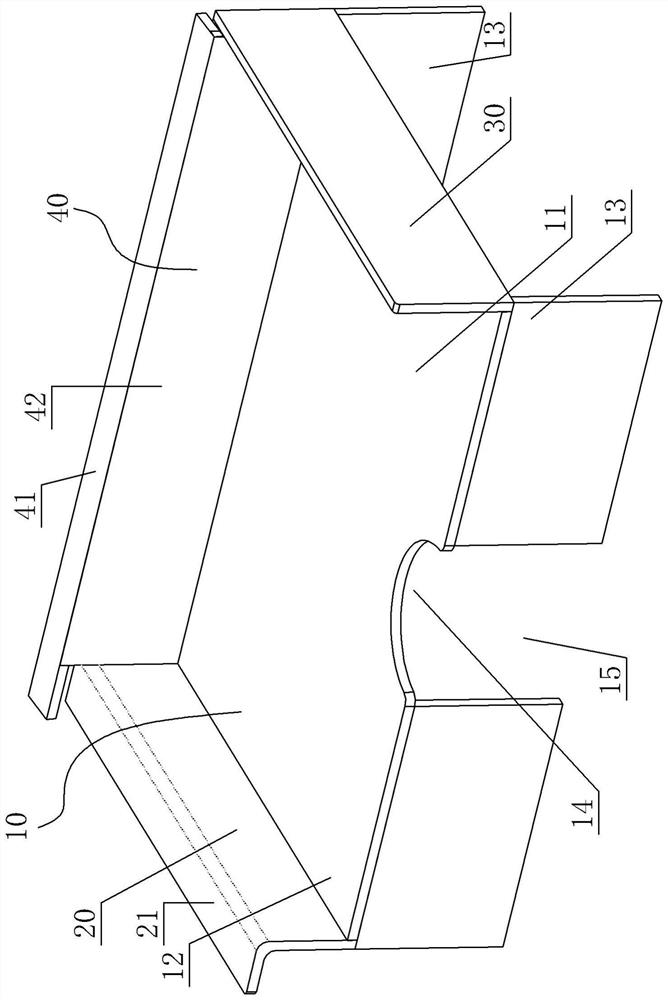

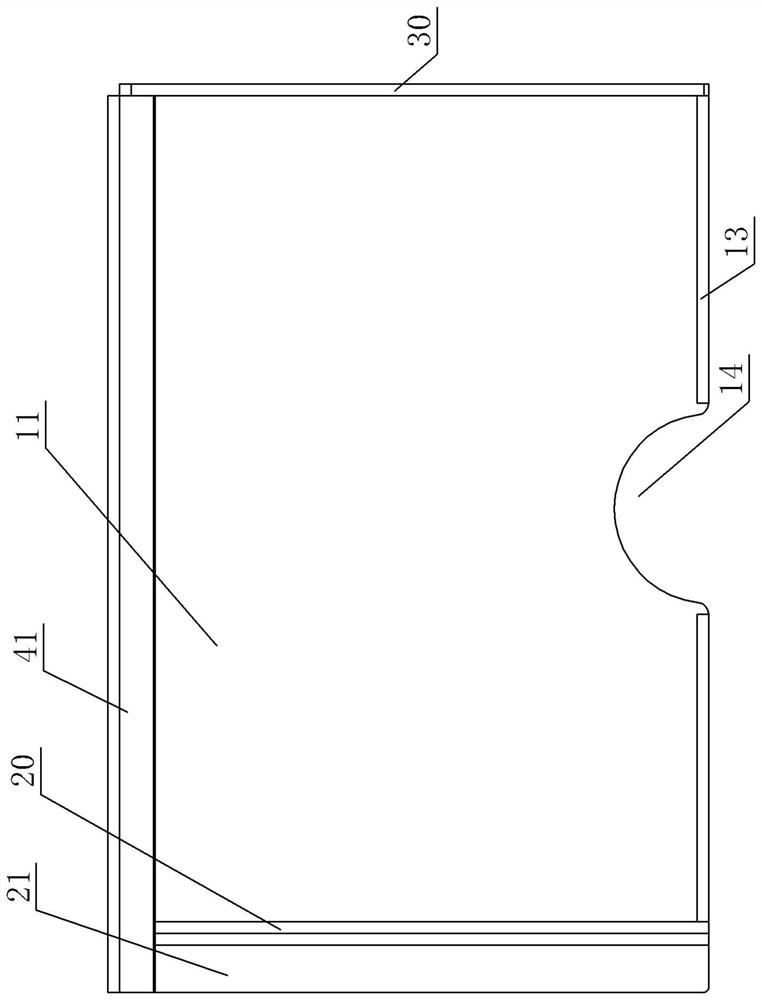

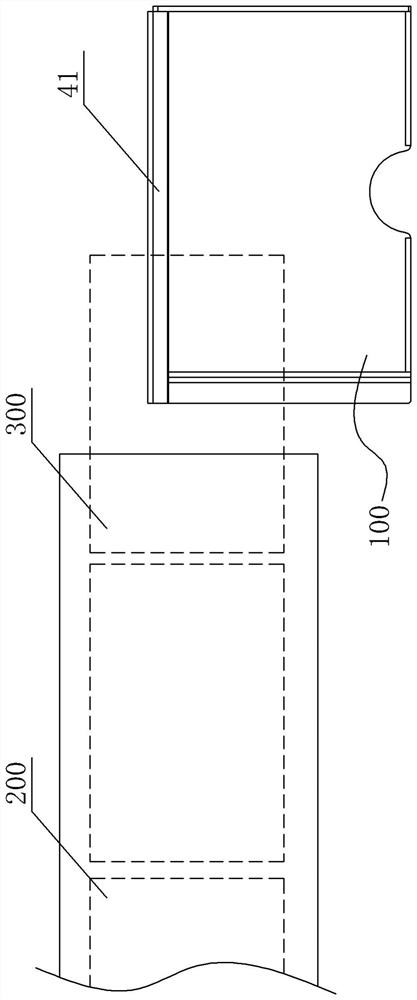

[0028] A tooling for handling large-sized soft materials, see Figure 1-Figure 2 , which includes a concave material placement cavity 10, a front end plate 20, a rear end plate 30 and a side support rail 40;

[0029] The front end of the concave material placing cavity 10 is convexly provided with a front end plate 20, the rear end of the concave material placing cavity 10 is convexly provided with a rear end plate 20, and one side of the concave material placing cavity 10 is provided with a side support rail 40, The rail surface 41 of the side support rail 40 extends from the front to the rear and has a width W.

[0030] In specific implementation, the width W is between 5% and 10% of the width of the material, so as to ensure that the sheet material receives sufficient supporting force and does not bend in the length direction.

[0031] In a specific embodiment, the rail surface 41 is higher than the upper end position of the front end plate 10 and the rear end plate 20, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com