Rotary cage type cleaning machine and cleaning method thereof

A cleaning machine and rotating cage technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of workpiece collision, workpiece damage, inability to clean, etc., to ensure a safe distance and avoid collisions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

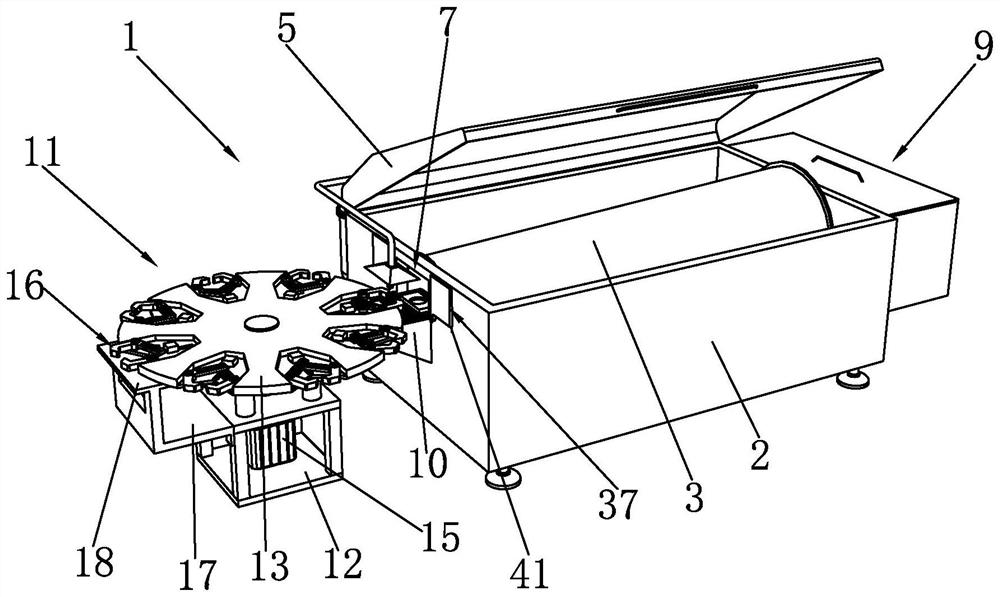

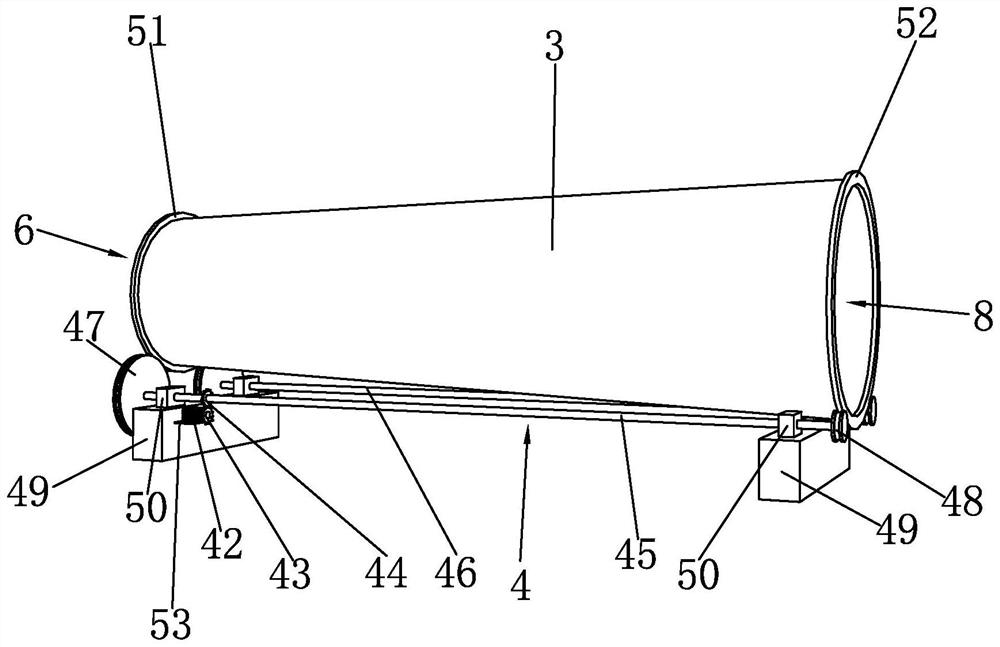

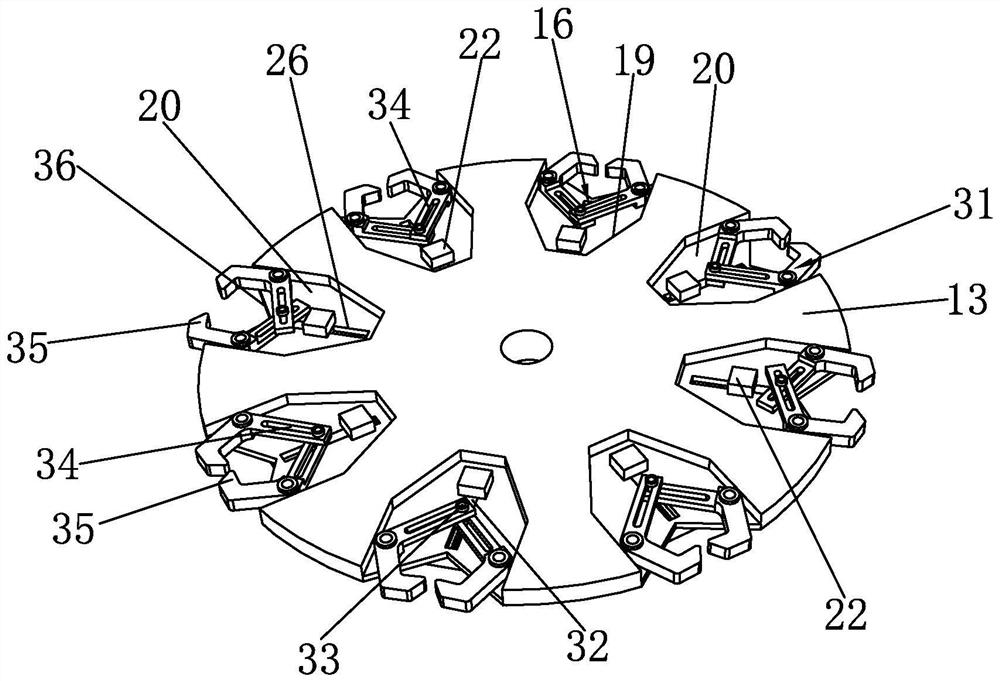

[0040] Such as Figure 1 to Figure 5 As shown, it is a tumbler cleaning machine of the present invention, which includes a body 1, a body 1 including a chassis 2 and a tumbler 3, the tumbler 3 is controlled by a drive assembly 4 to rotate in the chassis 2, and the top surface of the chassis 2 is rotatably connected There is a cover 5, one end of the tumbler 3 is provided with a first opening 6, the cabinet 2 is correspondingly provided with a feed inlet 7, the other end of the tumbler 3 is provided with a second opening 8, and the cabinet 2 is correspondingly provided with a discharge port 9, The feeding port 7 is connected with a conveying table 10 and a feeding mechanism 11. The feeding mechanism 11 controls the workpieces 57 to be sent to the conveying table 10 one by one. The conveying table 10 sends the workpieces 57 into the tumbler 3 for cleaning, and the cleaning of the workpieces 57 is completed. Afterwards, send out from discharge port 9.

[0041] The feeding mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com