Crushing and brick making device for recycling construction waste

A construction waste and crushing box technology, which is applied in the direction of climate sustainability, sustainable waste treatment, grain treatment, etc., can solve the problems that affect the quality of brick making, cannot be classified, and cannot distinguish wood from them, so as to improve the flexibility of the device, Guaranteed quality and prevent clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

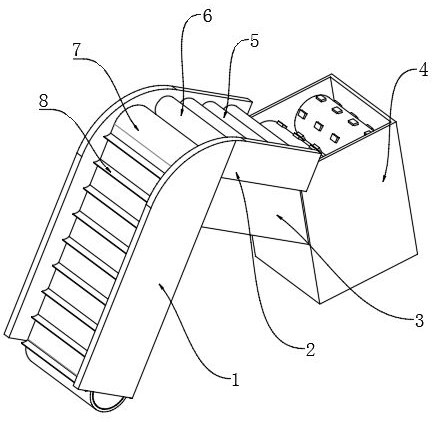

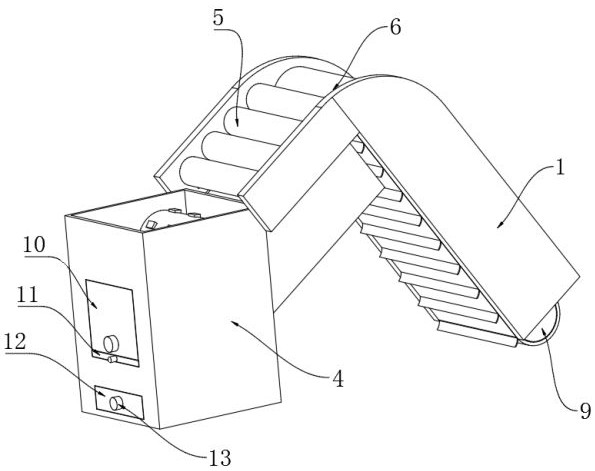

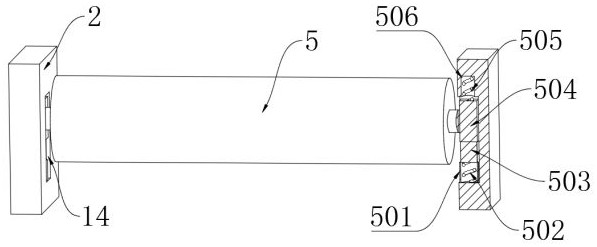

[0034] A crushing brick making device for recycling construction waste, such as Figure 1-3As shown in the figure, it includes a first support plate 1 and a second support plate 2; the outer wall of the first support plate 1 is fixedly connected to the outer wall of the second support plate 2; the inner wall of the first support plate 1 is rotated and connected with a uniform Distributed transfer rollers 9; the outer wall of the transfer roller 9 is provided with a conveyor belt 7; the outer wall around the conveyor belt 7 is fixedly connected with evenly distributed arc baffles 8; the inner wall of one side of the second support plate 2 is rotatably connected with a fixed roller 6; The inner wall of one side of the second support plate 2 is provided with evenly distributed built-in grooves 14; the outer wall of one side of the built-in groove 14 is fixedly connected with a moving roller 5 by screws; The crushing device is blocked, and the arc baffle 8 can also prevent the con...

Embodiment 2

[0039] A broken brick-making device for construction waste recycling, in order to ensure the effectiveness of the classification recycling box 3 for the classification of construction waste, such as Figure 4 As shown, this embodiment makes the following additions on the basis of Embodiment 1: an inclined guide block 301 is fixedly connected to the inner wall of one side of the sorting and recycling box 3; the inner wall of one side of the inclined guide block 301 is provided with a limiting groove 302; The inner wall of one side of the box 3 is fixedly connected with a fixed sorting plate 306; the outer wall of one side of the fixed sorting plate 306 is rotatably connected with a rotating screening plate 307; the inner wall of the rotating screening plate 307 is provided with evenly distributed screening holes; the outer wall of the rotating screening plate 307 side It is slidably connected to the inner wall of one side of the limit groove 302; by rotating the screening plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com