Big data-based rotary cultivator with high soil condition self-adaption capability

An adaptive, rotary tiller technology, applied in the field of rotary tiller, can solve the problems of easy damage to the blade, single rotary tiller function, etc., and achieve the effect of improving compressive strength, increasing service life, and comfortable operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

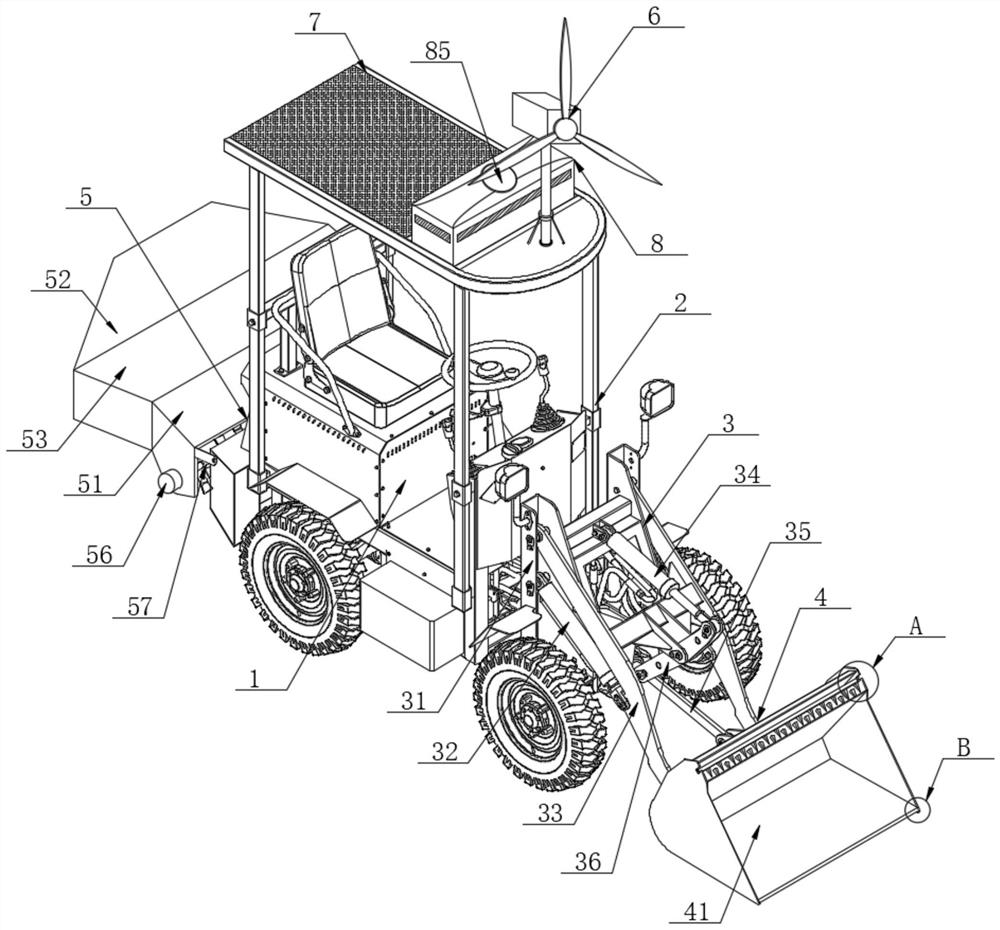

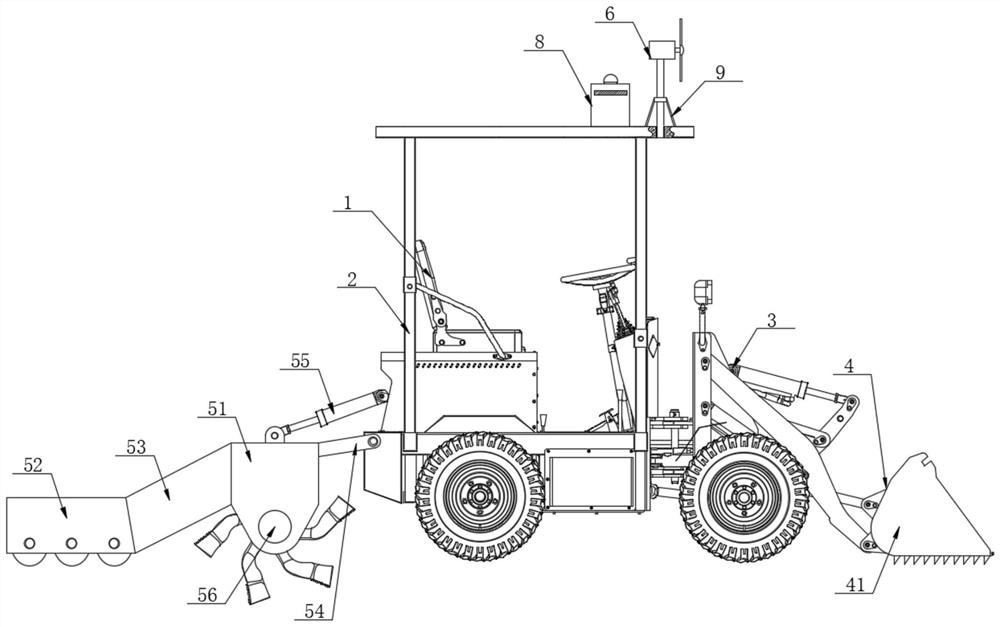

[0056] Refer to the manual attached Figure 1-6 , a rotary tiller with strong self-adaptive soil condition based on big data according to an embodiment of the present invention includes a driving device 1, a scaffold 2 is fixedly installed on the driving device 1, and a lifting mechanism is arranged at the front end of the driving device 1 3. The end of the lifting mechanism 3 away from the driving device is provided with a rotary tillage pretreatment mechanism 4 , and the rear end of the driving device 1 is provided with a rotary tillage and ridge mechanism 5 .

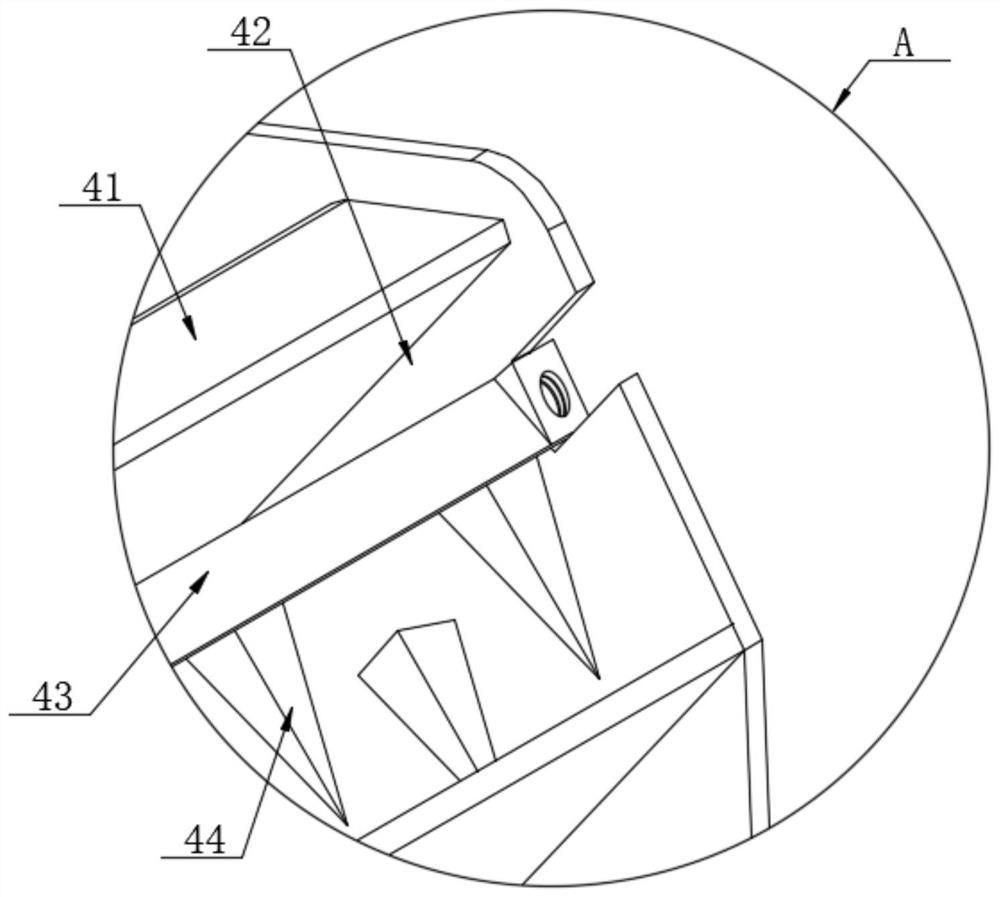

[0057] Further, the lifting mechanism 3 includes a mounting frame 31 fixedly mounted on the front end of the driving device 1, the mounting frame 31, a lifting arm 33 is hingedly installed at the top of the front end of the mounting frame 31, and a second adjusting arm 36 is provided in the middle of the front end of the mounting frame 31. , and the middle part of the second adjusting arm 36 is hinged with the mounti...

Embodiment 2

[0061] Refer to the manual attached Figure 1-2 and Figure 7-8 , the rotary tillage and ridge mechanism 5 of an embodiment of the present invention includes a motor 56, a rotary tiller casing 51, a ridge casing 52, and a mudguard shell 53 connecting the rotary tiller casing 51 and the ridge casing 52, and starts The ridge casing 52 is arranged in a constricted shape toward the end away from the driving device 1, the motor 56 is fixedly installed on one end of the rotary tiller casing 51, and the top of the end of the rotary tiller casing 51 facing the driving device 1 is welded with connecting lugs on both sides. 54. One end of the two connecting lugs 54 away from the rotary tiller casing 51 is connected to the driving device 1 in rotation through the connecting rod. The top surface of the shell 51 is hinged, and a rotary tiller frame 57 is installed inside the rotary tiller casing 51, which is drivingly connected with the drive shaft of the motor 56. Each group of rotary t...

Embodiment 3

[0064] Refer to the manual attached Figure 1-2 and Figure 10-11 , according to an embodiment of the present invention, a rotary tiller with strong self-adaptive soil condition capability based on big data is provided with an air outlet mechanism 8 on the top of the shelf 2, and the air outlet mechanism 8 includes a fixed installation on the top of the shelf 2. The casing 81, the top of the inner cavity of the casing 81 is fixedly embedded with an exhaust fan 82, the top of the casing 81 corresponding to the position of the exhaust fan 82 is fixedly installed with a protective shed 85 with a bracket at the bottom, and the top surface of the casing 81 is located at the protective shed 85. Parts on both sides are inclined downward, and semiconductor refrigeration chips 83 are fixedly installed on the peripheral side of the inner cavity of the casing 81 .

[0065] It should be noted that, during the working process of the rotary tiller, the operator can control the exhaust fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com