Telescopic spacing bar, telescopic hollow glass and manufacturing method of telescopic hollow glass

A spacer, telescopic technology, used in windows/doors, building components, sealing devices, etc., can solve problems such as reducing thermal conductivity, and achieve the effect of reducing thermal conductivity, reducing building energy consumption, and improving appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

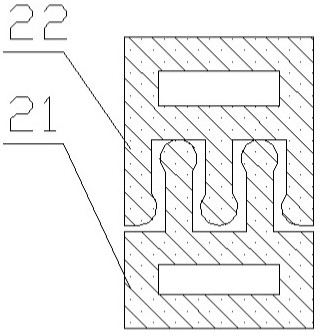

[0060] Example 1: Reference figure 1 , a telescopic spacer, comprising the lower part 21 of the spacer, the upper part 22 of the spacer, the lower part 21 of the spacer and the upper part 22 of the spacer can adopt existing material spacers, such as aluminum alloy spacers , stainless steel spacer bar or warm edge spacer bar, etc., the lower part 21 of the spacer bar and the upper part 22 of the spacer bar are connected by a convex-concave structure. Contact with the upper part 22 of the spacer through a point (line) can better block heat conduction, so the telescopic spacer can not only eliminate the stress and glass deformation of the edge sealing structure due to the breathing phenomenon of the hollow glass, but also greatly Improve the thermal insulation performance of the spacer.

Embodiment 2

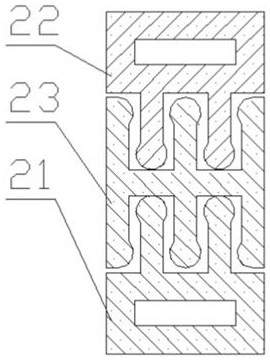

[0061] Example 2: Reference figure 2 , a telescopic spacer, comprising the lower part 21 of the spacer, the upper part 22 of the spacer and the middle part 23 of the spacer, which is basically the same as embodiment 1, except that the middle part 23 of the spacer is added, The relative movement of the spacer is increased from one place to two places, which not only helps to increase the amount of expansion and contraction, but also has a better effect of breaking the bridge, and further improves the heat insulation performance of the spacer.

Embodiment 3

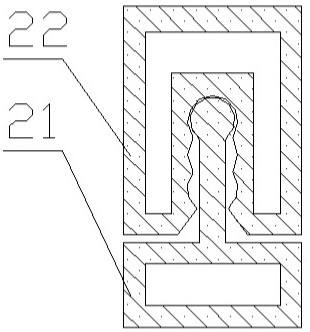

[0062] Example 3: Reference image 3 , a telescopic spacer, comprising the lower part 21 of the spacer and the upper part 22 of the spacer, which is basically the same as in embodiment 1, except that the contact between the lower part 21 of the spacer and the upper part 22 of the spacer For the cooperation between the rib and the groove, there are three gears in the groove, which is more conducive to the stability of the structure. When the insulating glass is assembled, the spacer can be in the middle gear, which is conducive to the spacer when the external temperature is high. The expansion of the hollow layer elongates, and the spacer shortens with the shrinkage of the hollow layer when the outside temperature is low; in addition, the heat conduction distance of the spacer is increased, and the heat insulation performance of the spacer is further improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com