Trousers packing equipment

A technology for packaging equipment and trousers, applied in the field of trousers packaging and packaging equipment, can solve problems such as poor regularity, low efficiency, creases, etc., and achieve the effects of saving and effective utilization, avoiding inconsistent folding shapes, and avoiding waste of box space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

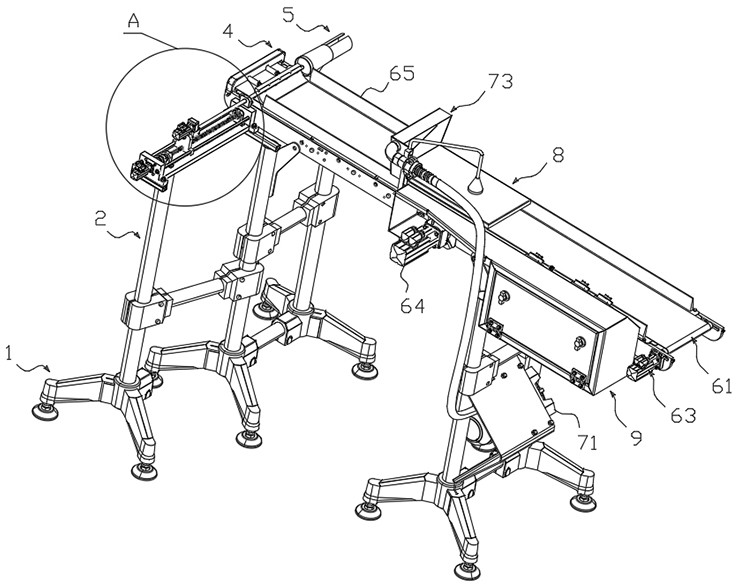

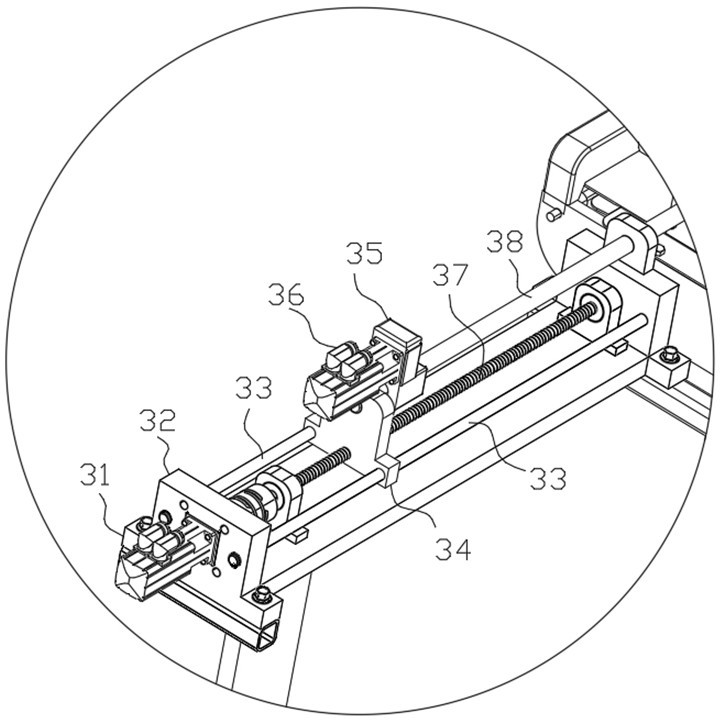

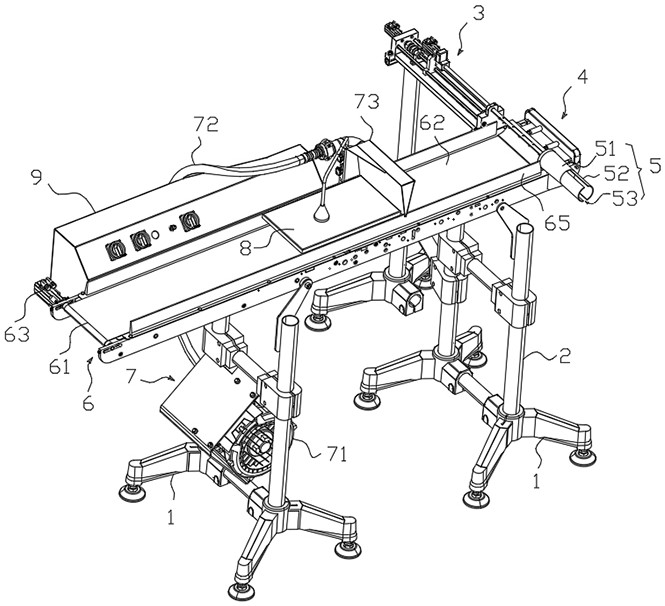

[0045] The present embodiment provides a trouser packing device, such as Figure 1-Figure 5Shown, comprising a base for supporting and fixing the apparatus 1 and rack 2, the rack 2 is installed with a conveyor mechanism for placing pants 6, directly above the conveyor 6 along the transmission direction in turn is provided with a sterilization mechanism 8 and a dust removal mechanism 7, near the end of the conveyor mechanism 6 is also installed to prevent the pants from continuing to move with the conveyor 6 guide mechanism 4; before the guide mechanism 4 intervenes, the pants remain placed on the conveyor mechanism 6 in the initial state along the conveyor 6 straight motion, When one end of the pants reaches and contacts the guide mechanism 4, the pants move along the surface of the guide mechanism 4, and in contact with the storage mechanism 3, the storage mechanism 3 includes a shaft 38 may simultaneously do radial to complex linear movement and axial rotation, the shaft 38 is in...

Embodiment 2

[0050] The present embodiment is a preferred embodiment of the present application, see the appendix to the specification Figure 1- Figure 9A kind of trouser packing and packaging apparatus shown, comprising a base 1 and a rack 2 for supporting and fixing the device, the rack 2 is installed with a conveyor mechanism for placing pants 6, directly above the conveyor 6 is successively provided with a sterilization mechanism 8 and a dust removal mechanism 7 along the transmission direction, in the position near the end of the conveyor mechanism 6 is also installed to block the pants from continuing to move with the conveyor mechanism 6 4; before the guide mechanism 4 intervenes, Pants maintain the initial state placed on the conveyor mechanism 6 along the conveyor mechanism 6 straight motion, when one end of the pants arrives and contacts the guide mechanism 4, the pants along the surface of the guide mechanism 4, and contact with the storage mechanism 3, the storage mechanism 3 inclu...

Embodiment 3

[0054] In order to better realize the rolling and storage of the pants, the present embodiment further refines the guiding mechanism 4 on the basis of Example 1 or Example 2, and is specifically combined Figure 4 and Figure 5 As shown, the guide mechanism 4 includes a housing fixed mounted on the rack 2 or the transmission mechanism 6, a plurality of spring seats mounted on the housing 43, a second spring 42 disposed on the spring seat 43, the end of any second spring 42 is connected to the guide block 41. Further, the guide block 41 near the hinge 38 side having a curved surface, the lower edge of the curved surface is close to the upper surface of the transmitting mechanism 6, the upper edge of the curved surface is higher than the horizontal plane where the axis of the hinge 38 is located.

[0055]The curved surface of the guide block 41 in the present embodiment is extended along the circumferential sidewall of the shaft 38 to form an extension of the wrapping angle of not les...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com