Large wind power gear box turnover machine

A wind power gearbox and turning machine technology, which is applied in the direction of hoisting device, hoisting equipment safety device, climate sustainability, etc., can solve the problems of low safety, cumbersome operation process, falling, etc., to improve processing efficiency, Simple and convenient operation, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

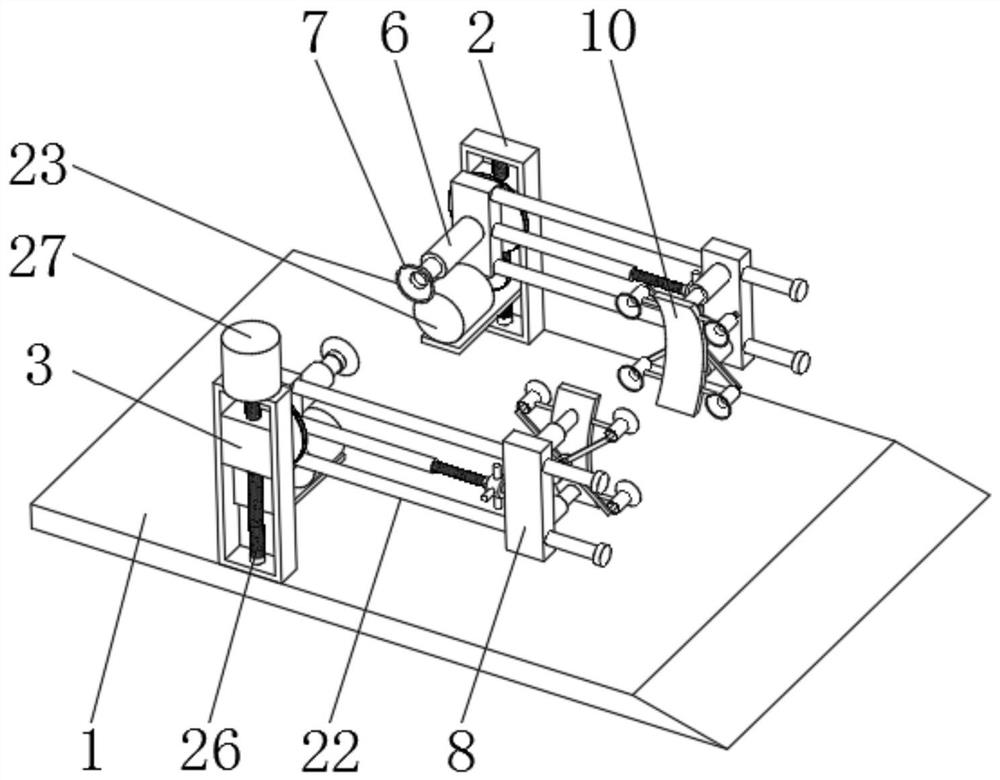

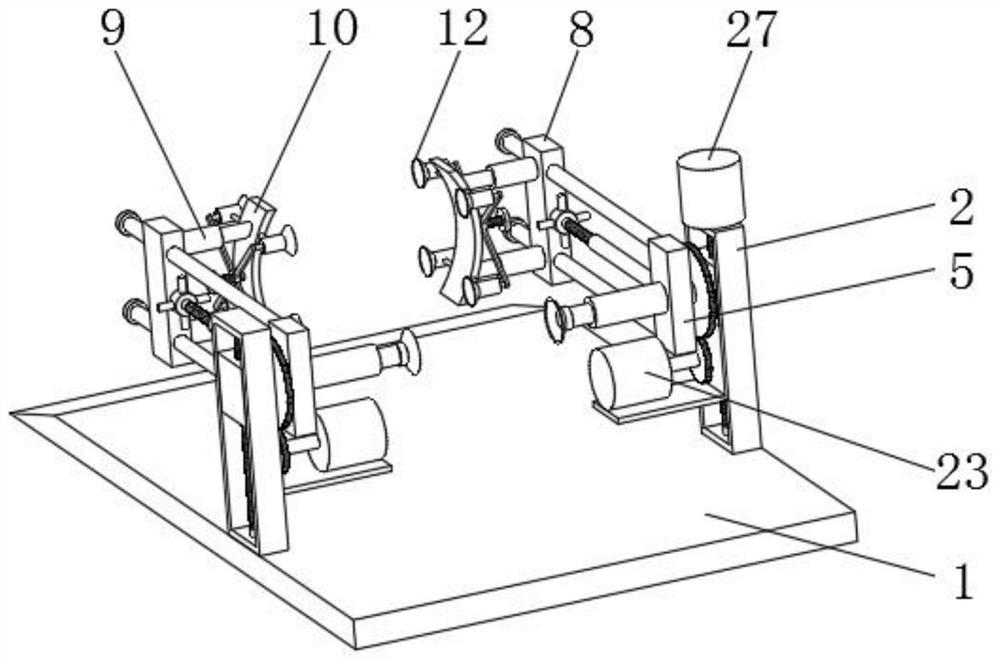

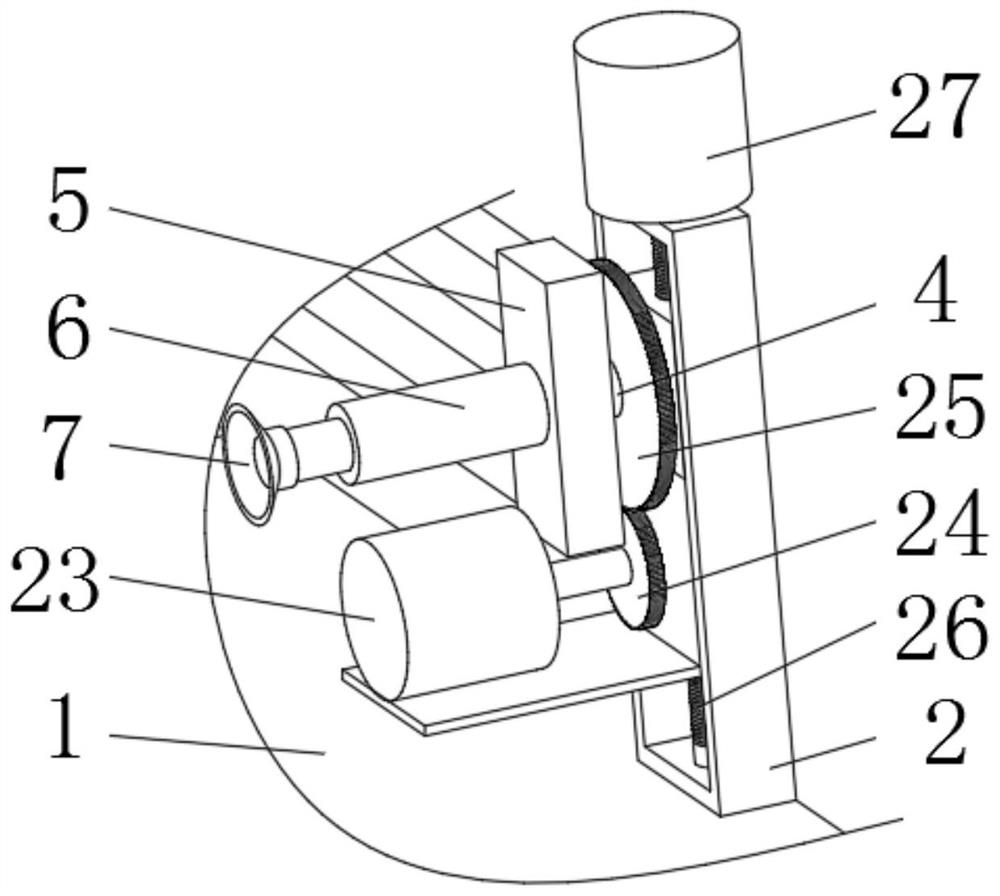

[0041] Example: Reference Figure 1-8 The shown large-scale wind power gearbox turning machine includes a base 1. Two vertical slide rails 2 are installed on the top of the base 1. The two vertical slide rails 2 are jointly connected with a lifting drive assembly, and the lifting drive assembly is connected to There is an overturning drive assembly, the lifting drive assembly can drive the overturning drive assembly to move up and down, the overturning drive assembly is connected with a clamping assembly for clamping and fixing the wind power gearbox, and the clamping assembly is connected with two sets of adsorption stabilization components arranged symmetrically to each other , the adsorption stabilizing component is used to further adsorb and fix the wind power gearbox, and the turning drive component can drive the clamping component to turn over.

[0042] With the above structure, the wind power gearbox can be clamped and fixed before turning over through the setting of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com