Interface-controllable material gene recombination blending modification technology

A technology of genetic recombination and blending modification, which is applied in the field of material blending and modification, can solve the problems of uneven distribution of monomer materials, uncontrollable distribution, and inability to process polymer composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

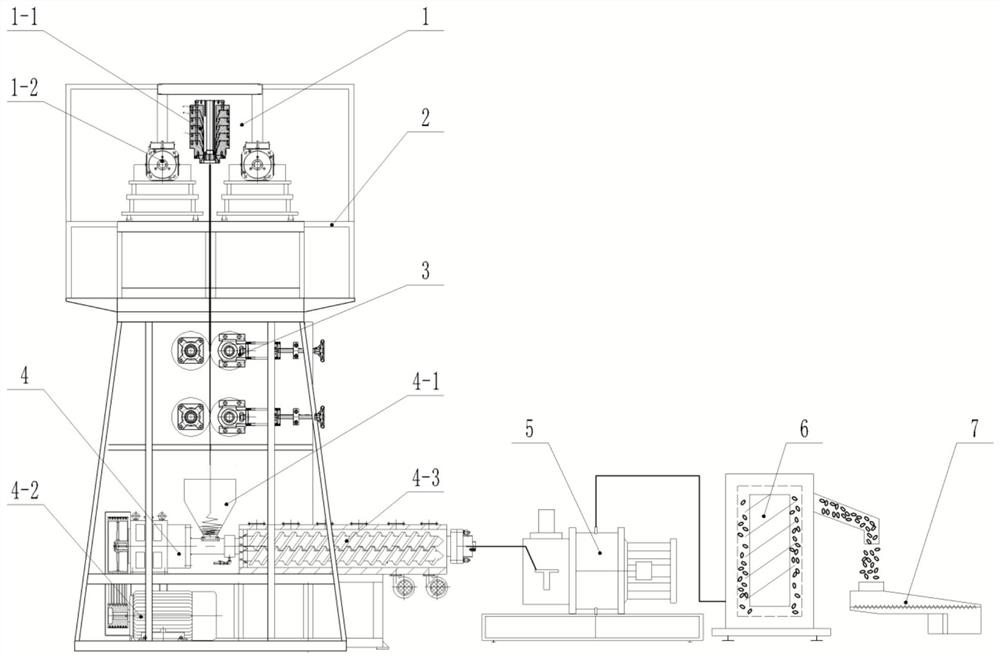

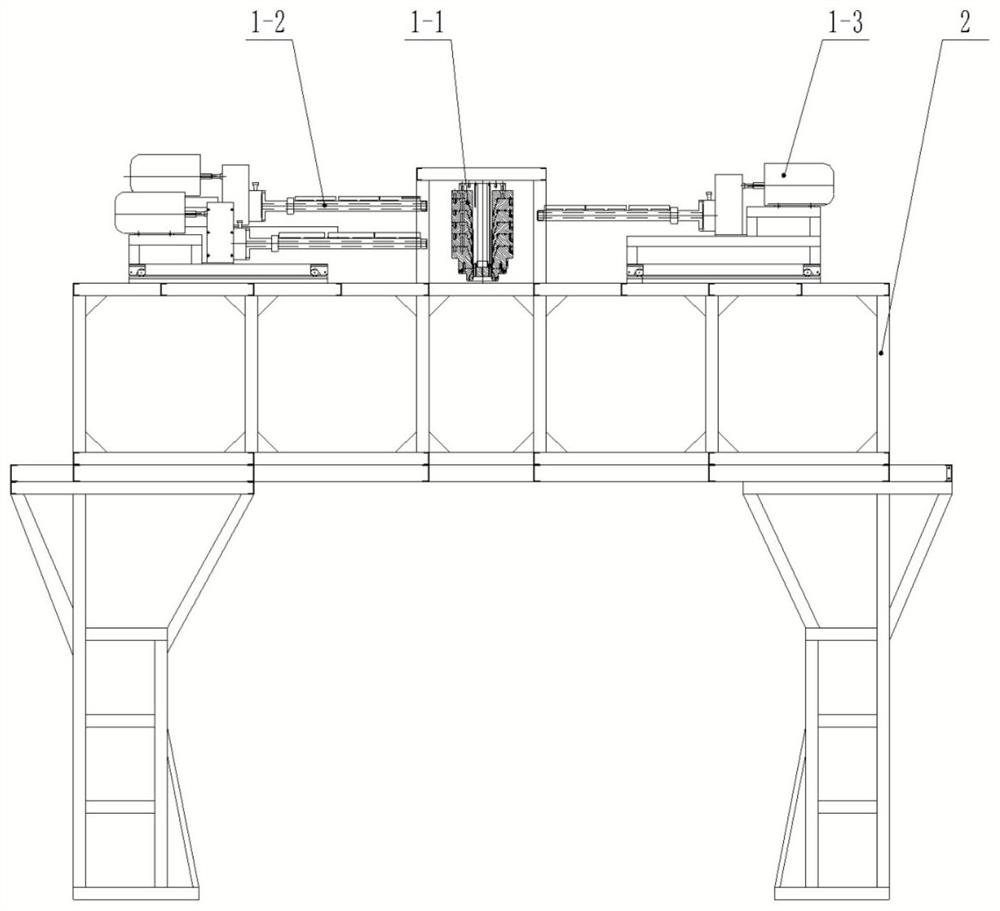

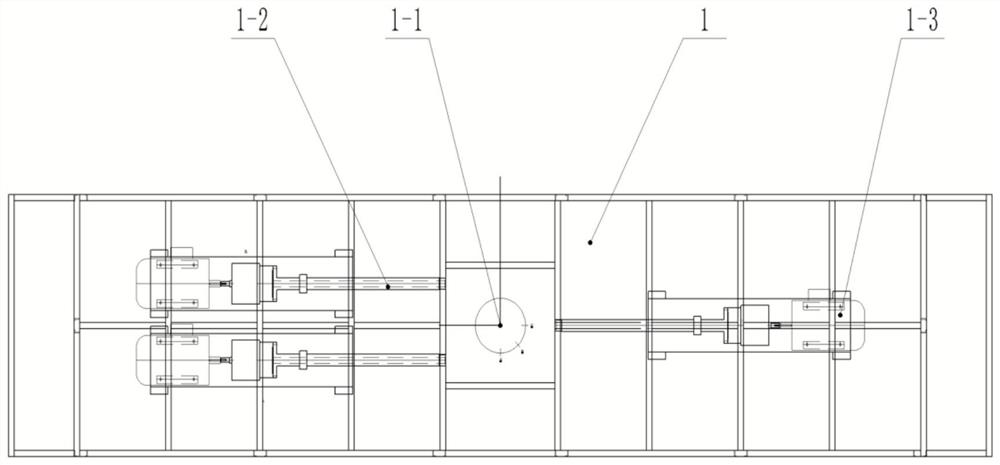

[0017] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. This embodiment prepares three sets of Taking the material gene recombination composite material with controllable interface as an example, a kind of interface controllable material gene recombination blending modification technology involved in the present invention is summarized, and it is not limited to the three-component interface prepared in this example. Controlled material genetic recombination composite materials, if more components of the interface controllable genetic recombination composite materials are required, the number of single-screw extruders in the material gene recombination multi-unit plasticizing extrusion device can be increas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com