Automatic spring tubing device and system

A tube loading and automatic technology, applied in the direction of measuring devices, reducing greenhouse gases, instruments, etc., can solve the problems of inability to guarantee the quality stability of cladding tubes, inconsistent compression lengths of compression springs, and different pressing forces of fuel pellets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

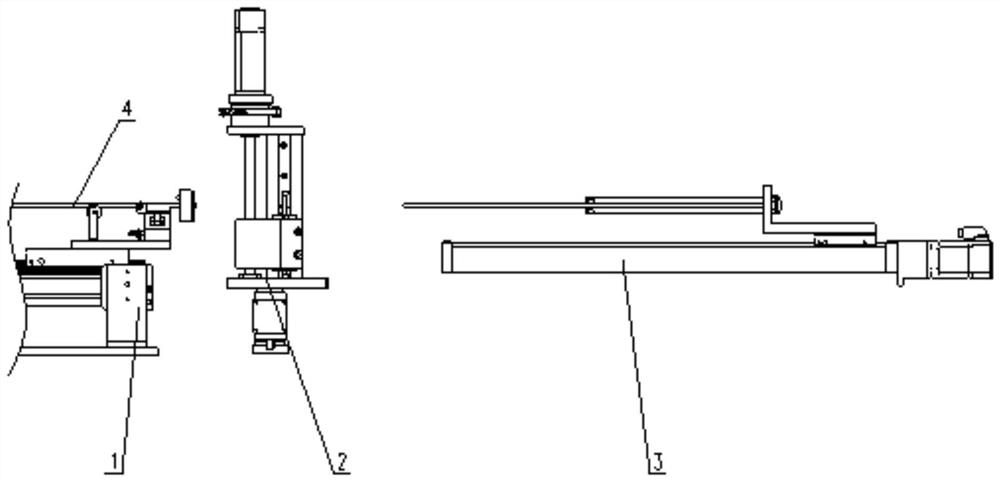

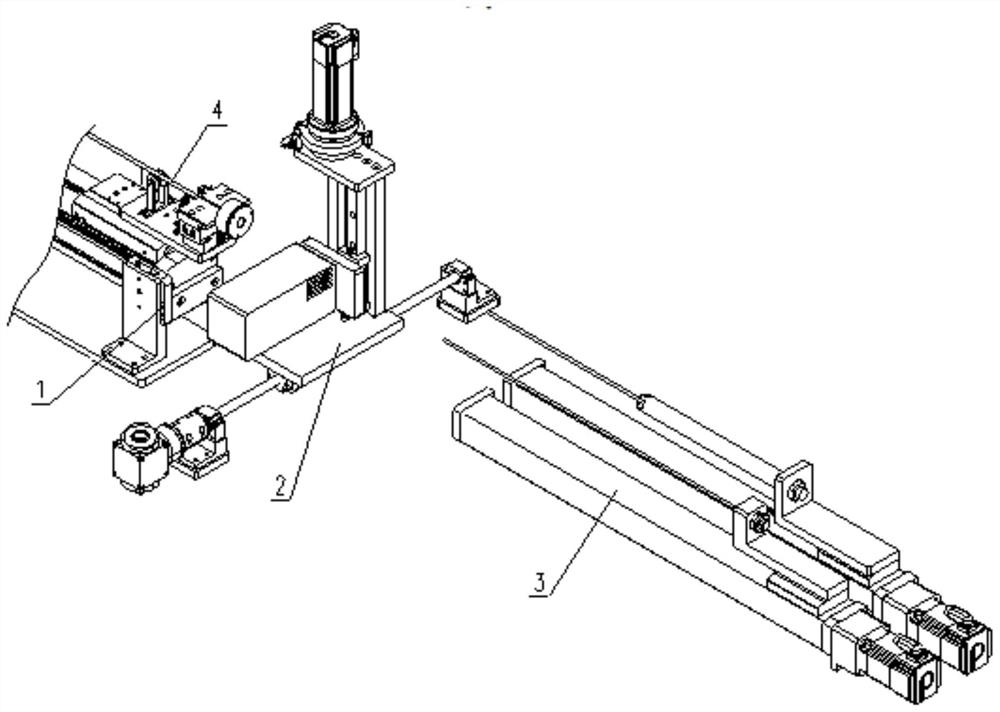

[0030] Such as figure 1 As shown, the present invention discloses a spring automatic tube loading device, which includes a tube loading mechanism 1, a material storage mechanism 2 and a push mechanism 3, the material storage mechanism 2 is used to store a compressed spring, and the diameter of the outer ring of the compressed spring is larger than that of the cladding tube 4 , so that after the compression spring is loaded into the cladding tube 4, the outer ring of the compression spring can generate a large enough friction force with the inner wall of the cladding tube 4, thereby compressing the pellet in the cladding tube 4.

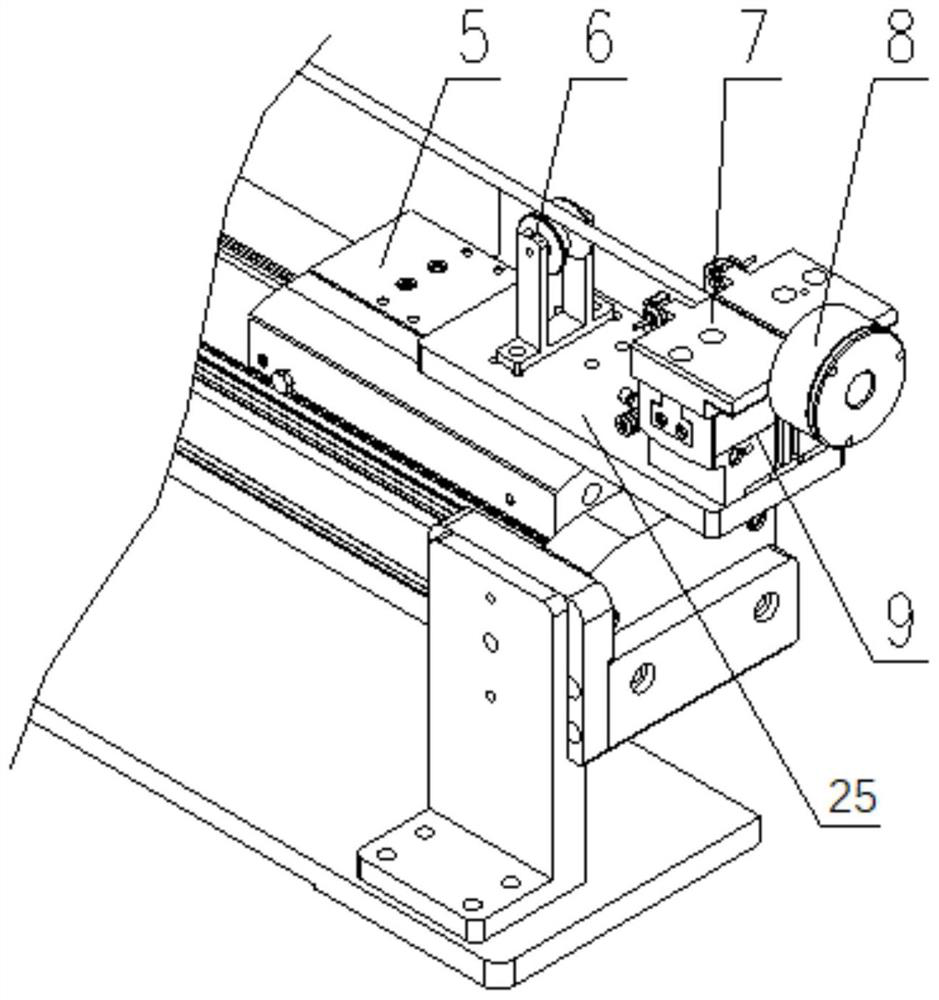

[0031] Such as figure 1 , 2 As shown, the pushing mechanism 3 and the tube loading mechanism 1 are separately arranged on both sides of the storage mechanism 2, and the tube loading mechanism 1 is used to support and fix the cladding tube 4; the pushing mechanism 3 includes a push rod assembly and a measuring assembly.

[0032] Specifically, the measu...

Embodiment 2

[0047] This embodiment discloses an automatic spring tube loading system, which includes a glove box, a positioning assembly, and the above-mentioned automatic spring tube loading device. The glove box is divided into three areas by three partition plates. The push mechanism 3, the material storage mechanism 2 and the tube loading mechanism 1 are successively arranged in three areas. The positioning assembly includes a positioning block 8. The center of the positioning block 8 is provided with a positioning hole. The positioning block 8 is installed between the storage mechanism 2 and the loading mechanism. The partition plate between the tube mechanisms 1, and the positioning hole communicates with the input end of the cladding tube 4.

[0048] Specifically, the material storage mechanism 2 is arranged in the middle area of the three areas of the glove box, and the pushing mechanism 3 and the tube loading mechanism 1 are respectively arranged in two areas on both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com