Plasma fly ash melting device and use method thereof

A melting device and plasma technology, applied in the direction of combustion method, combustion type, lighting and heating equipment, etc., can solve the problems of incomplete melting, increased energy consumption, light specific gravity of fly ash, etc., achieve good melting effect, facilitate combustion and Decomposition, the effect of reducing the content of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following is attached Figure 1-6 The application is described in further detail.

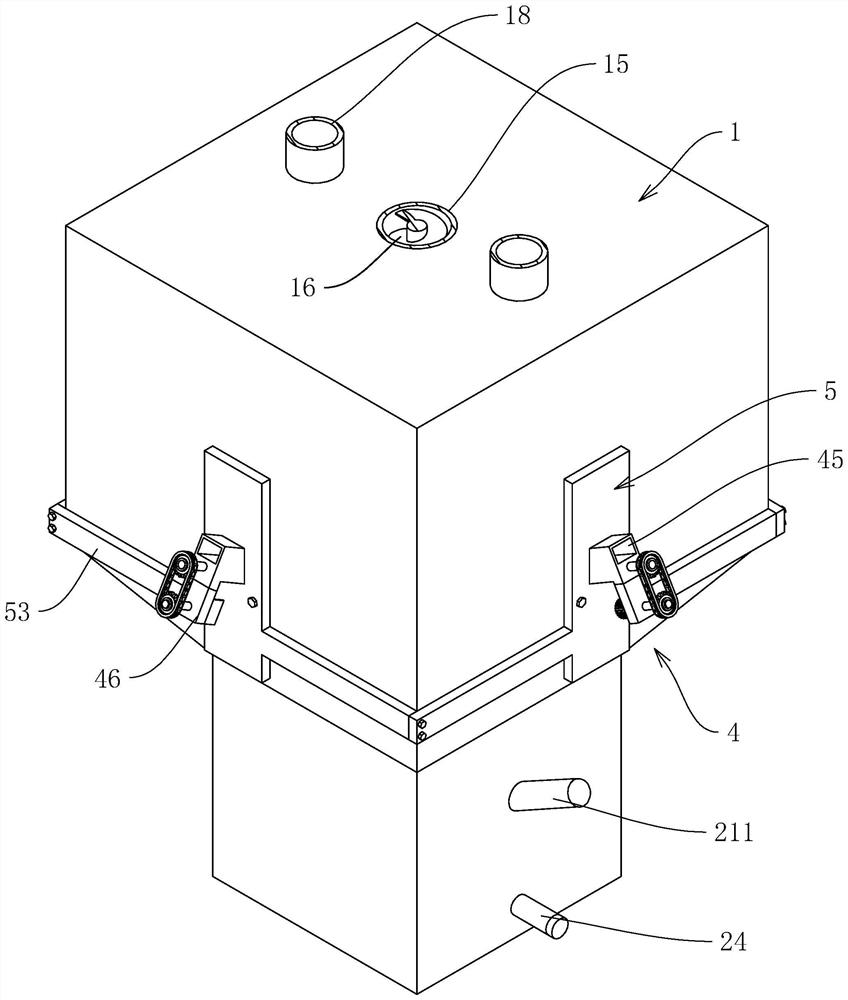

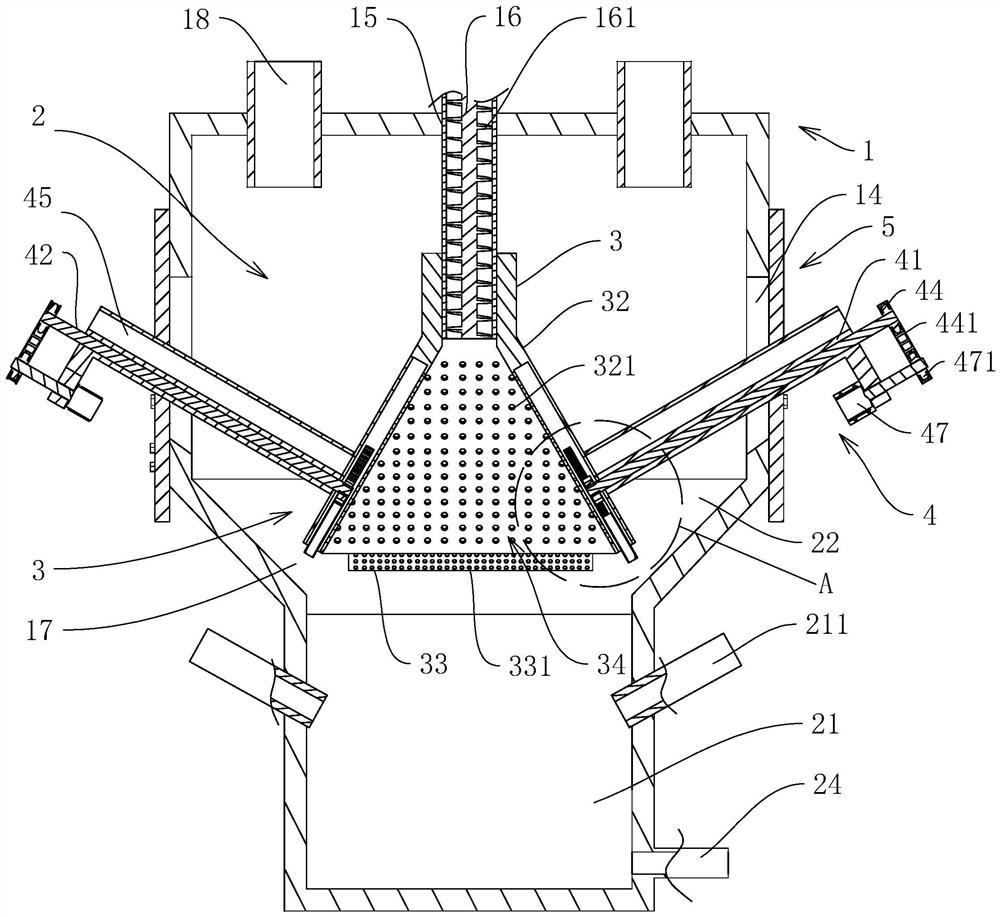

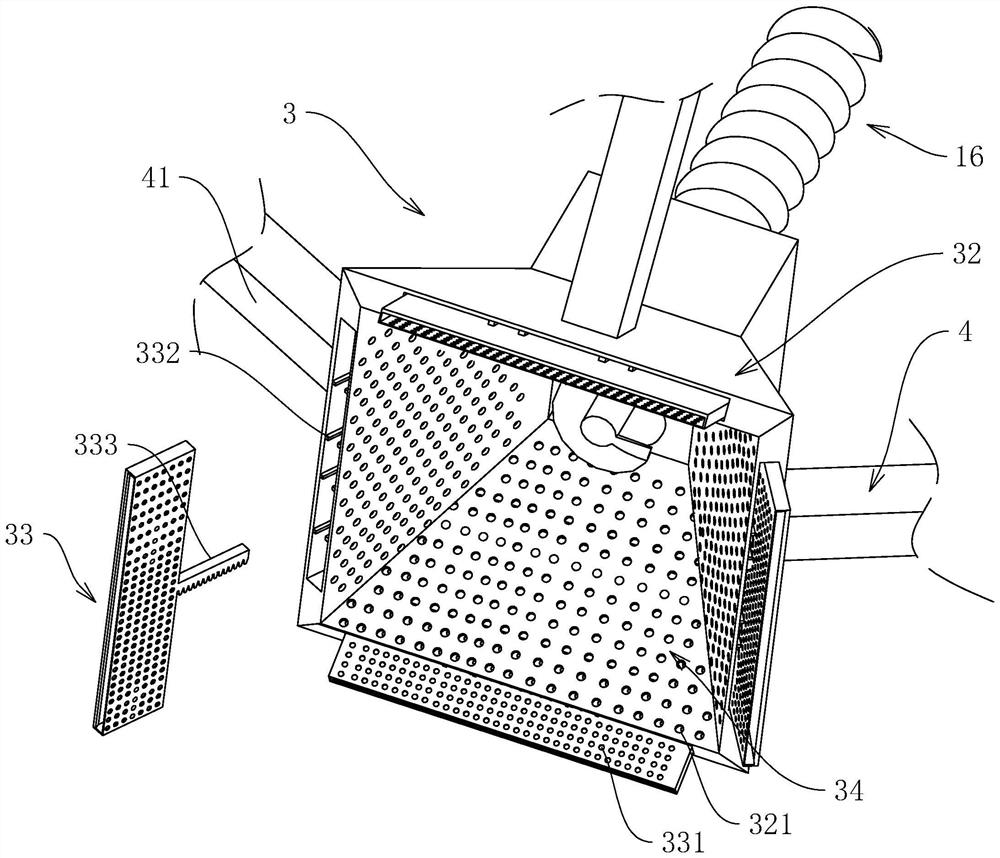

[0049] The embodiment of the present application discloses a plasma fly ash melting device. refer to figure 1 and figure 2 , a plasma fly ash melting device includes a melting furnace body 1, the melting furnace body 1 includes a housing 11 and a housing chamber 2 in the middle for melting fly ash particles, the bottom of the housing chamber 2 is provided with a melting zone 21, the melting zone A plurality of plasma torches 211 are arranged on the side wall of 21, and the fly ash particles can become molten glass after being heated by the plasma torches 211 in the melting zone 21, and a discharge pipe 24 is provided at the bottom of the melting zone 21 for Discharge the treated fly ash particles. The top of the accommodation chamber 2 is connected with a feed pipe 15 for feeding and gas outlet pipes 18 located on both sides of the feed pipe 15, and an air supply seat 4 communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com