Continuous sewing production line and method for bandage with hook-and-loop fasteners

A Velcro, production line technology, applied in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problems of no back stitch function, velcro off thread, loss of the comfort of the bandage body, etc., to improve sewing efficiency, avoid two problems. The effect of off-line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

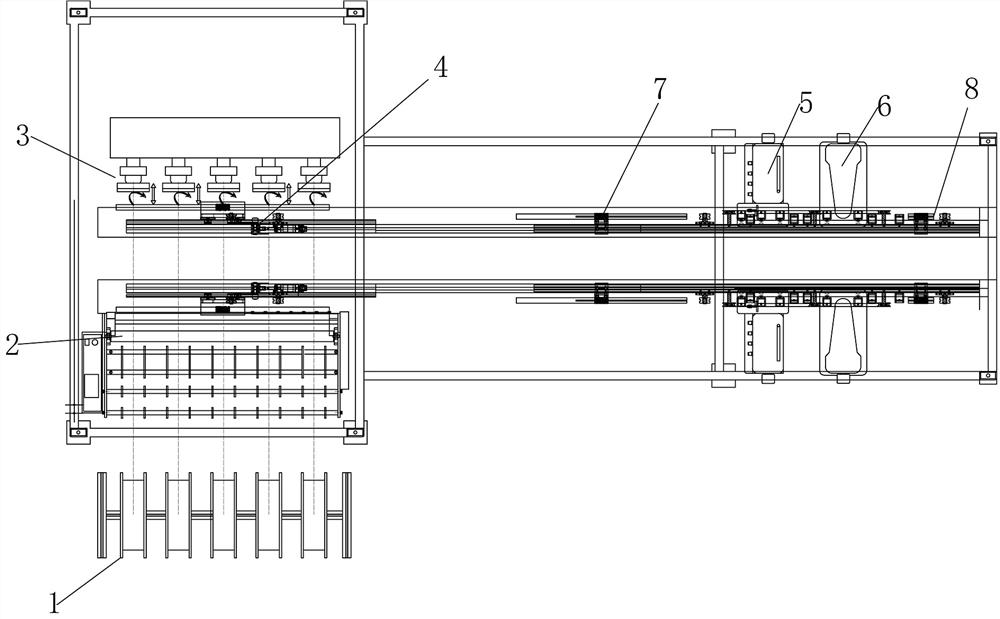

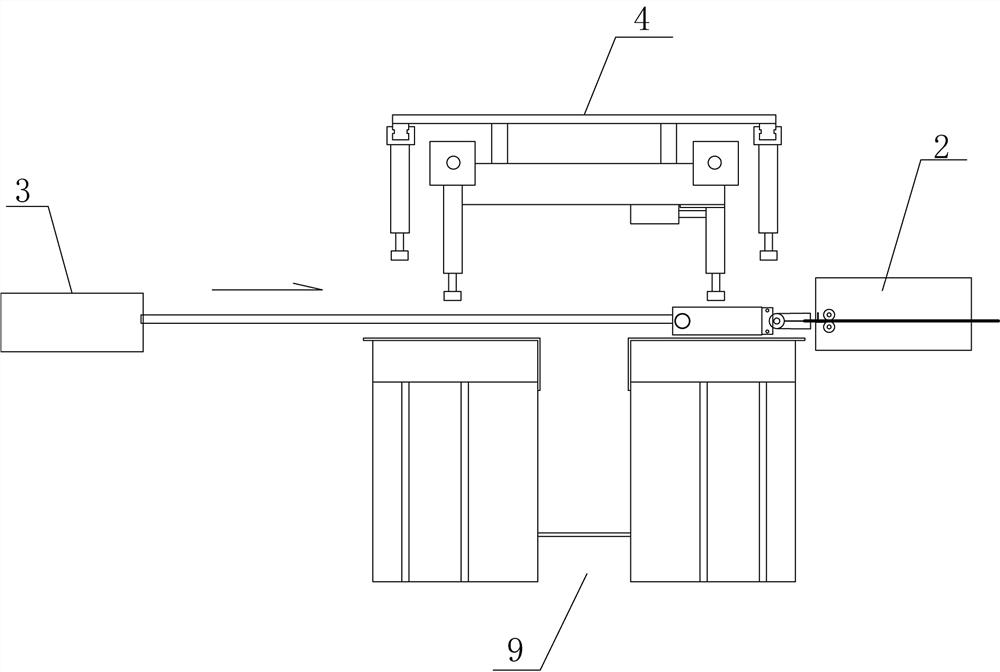

[0052] The preferred solution is as Figure 1 to Figure 14 As shown, a continuous sewing production line with Velcro bandages includes a bandage unwinding device 1, the output end of the bandage unwinding device 1 is provided with a fixed-length cloth feeding and cutting mechanism 2, and the fixed-length cloth feeding and cutting mechanism 2 is connected with a fixed-length The retrieving and turning mechanism 3 cooperates, and the fixed-length retrieving and turning mechanism 3 is used for grabbing the bandage 10 at a fixed length and turning over the bandage 10; The workbench 9 is provided with a transfer arm mechanism 4 above the workbench 9. The transfer arm mechanism 4 is used to transport the bandage 11 to be sewn to the sewing device. The output end of the sewing device is provided with an automatic roll-forming mechanism 8. A Velcro feeding mechanism 7 is arranged between the material turning mechanism 3, and the Velcro feeding mechanism 7 is used to stack the Velcro o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com