Method for removing aluminum from strong alkali solution and application

A technology of alkaline solution and aluminum remover, applied in chemical instruments and methods, alkali metal compounds, recycling technology, etc., can solve the problems of difficult processing and high cost, and achieve the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

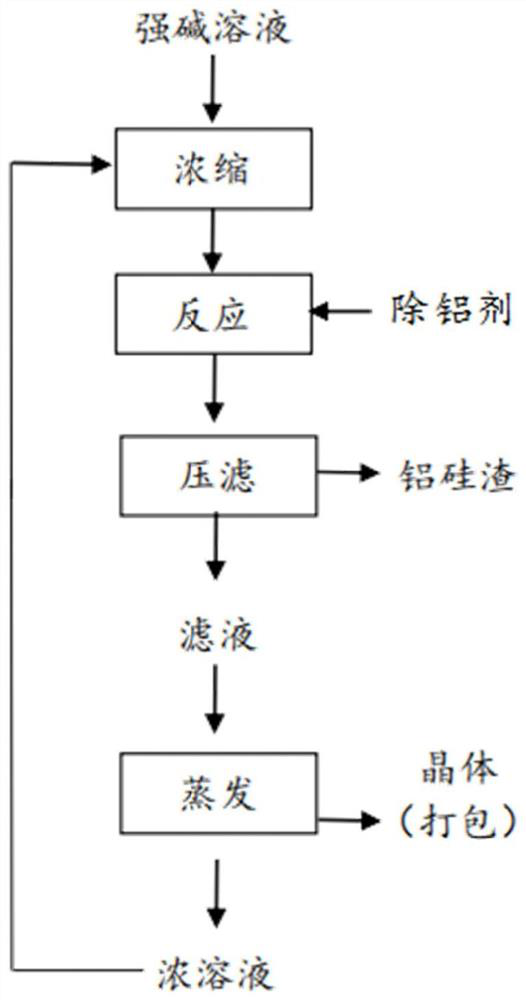

Method used

Image

Examples

Embodiment 1

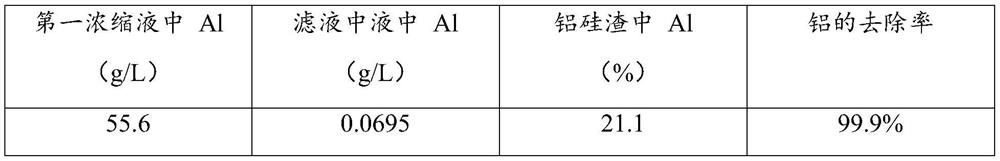

[0033] The method for removing aluminum in the sodium hydroxide strong alkali solution of the present embodiment comprises the following specific steps:

[0034] S1: Take aluminum-containing sodium hydroxide strong alkali solution, concentrate it, and filter to obtain 1.5L of the first concentrated solution, with a pH of 13.9 and a concentration of 83.0g / L, in which aluminum ions are 55.6g / L;

[0035] S2: Put 1.5L of the first concentrated solution in the reaction tank, add aluminum removing agent to the first concentrated solution, the aluminum removing agent is composed of 252.8g of sodium silicate and 98.5g of silicon dioxide, and mix to obtain a mixed solution;

[0036] S3: The mixed solution was reacted at 150°C for 2 hours, the temperature of the reacted solution was lowered to 25°C, the liquid-solid of the lye after the reaction was separated through a filter press, and dried to obtain 395.8g of aluminum-silicon slag and 1.2L of filtrate;

[0037] S4: Evaporate and crys...

Embodiment 2

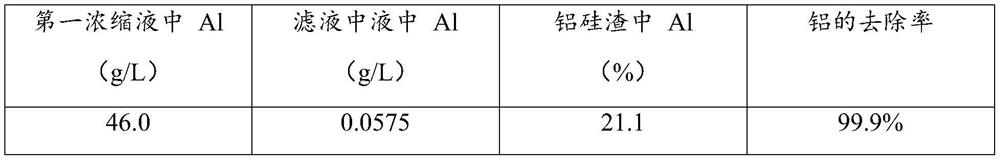

[0044] The method for removing aluminum in the lithium hydroxide strong alkali solution of the present embodiment comprises the following specific steps:

[0045] S1: Take aluminum-containing lithium hydroxide strong alkali solution, concentrate it, and filter to obtain 1.5L of the first concentrated solution, with a pH of 14.2 and a concentration of 62.5g / L, in which aluminum ions are 46.0g / L;

[0046] S2: Put 1.5L of the first concentrated solution in the reaction tank, add an aluminum removing agent to the first concentrated solution, the aluminum removing agent is composed of 174.5g of lithium silicate and 67.9g of silicon dioxide, and mix to obtain a mixed solution;

[0047] S3: React the mixed solution at 150° C. for 2 hours, cool down the reacted solution to 25° C., separate the liquid and solid from the reacted lye through a filter press, and dry to obtain 327.4 liters of aluminum-silicon slag and 1.2 L of filtrate;

[0048] S4: Evaporate and crystallize 1.2L of the fi...

Embodiment 3

[0054] The method for removing aluminum in the lithium hydroxide strong alkali solution of the present embodiment comprises the following specific steps:

[0055]S1: Take aluminum-containing lithium hydroxide strong alkali solution, concentrate it, and filter to obtain 1.5L of the first concentrated solution, with a pH of 14.8, a concentration of 70.2g / L, and a concentration of 4.5g / L of aluminum ions;

[0056] S2: Put 1.5L of the first concentrated solution in the reaction tank, add an aluminum removing agent to the first concentrated solution, the aluminum removing agent is composed of 17.1g of lithium silicate and 6.6g of silicon dioxide, and mix to obtain a mixed solution;

[0057] S3: React the mixed solution at 150° C. for 2 hours, cool down the reacted solution to 25° C., separate the liquid and solid from the reacted lye through a filter press, and dry to obtain 32.0 g of aluminum-silicon slag and 1.2 L of filtrate;

[0058] S4: Evaporate and crystallize 1.2L of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com