Loading equipment for compound oil phase

A technology of loading equipment and compound oil phase, applied in the directions of container handles, external accessories, internal accessories, etc., can solve the problem that the collecting device cannot achieve the effect of blocking rainwater, and achieve the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

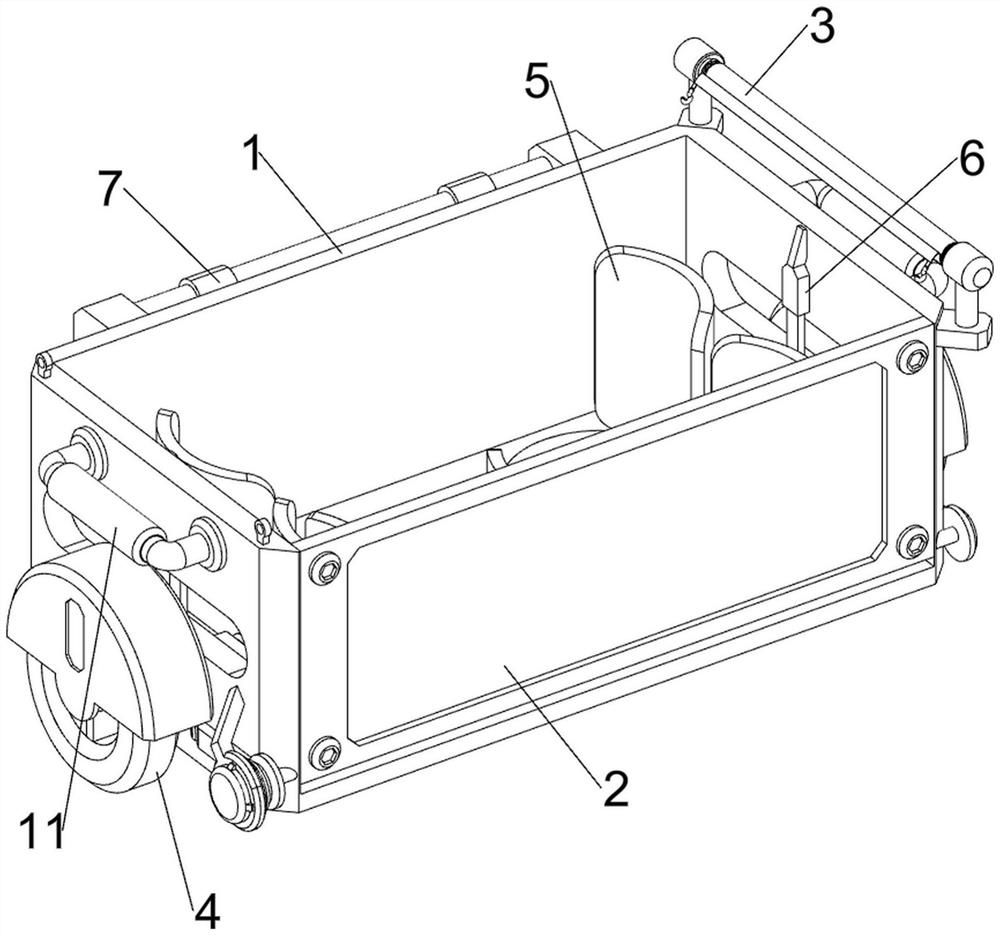

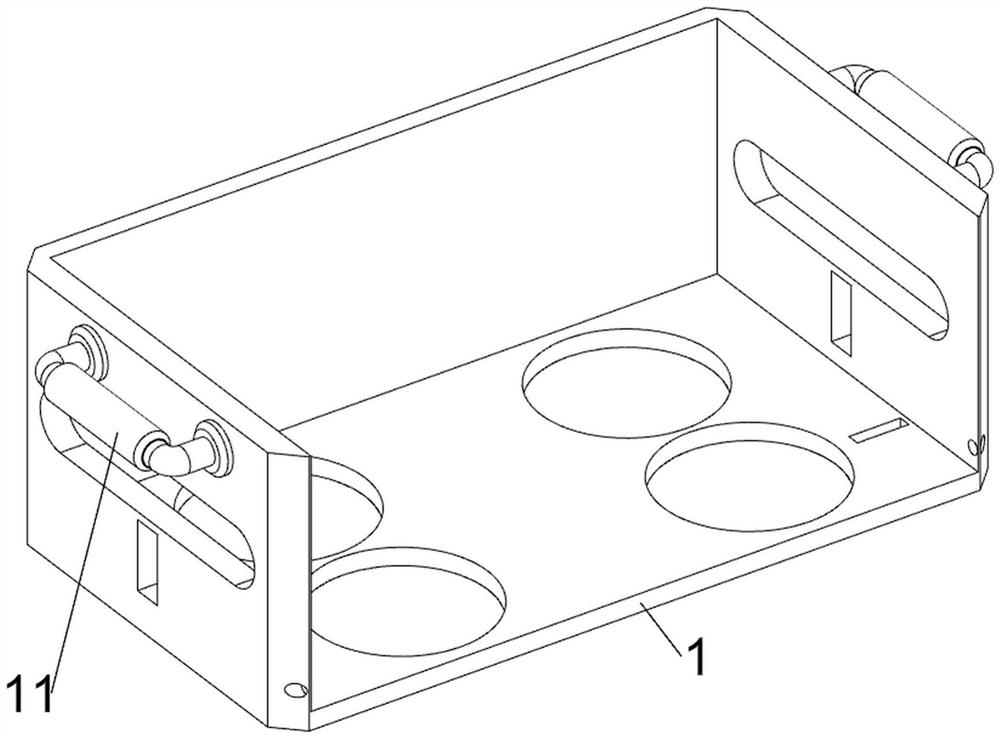

[0030] A loading device for complex oil phases such as Figure 1-2 As shown, it includes a loading box 1, a first handle 11, a blocking mechanism 2, and a cover mechanism 3. The left and right sides of the inner bottom wall of the loading box 1 are symmetrically opened with circular grooves front and rear, and the circular grooves of the loading box 1 are used to load compound oil. In contrast, the left and right sides of the loading box 1 are provided with first handles 11 through bolts, through the first handle 11, the loading box 1 is conveniently taken, and the loading box 1 is provided with a blocking mechanism 2, which is used to block the composite oil phase and load A cover mechanism 3 is provided above the box 1 for covering the top of the composite oil phase.

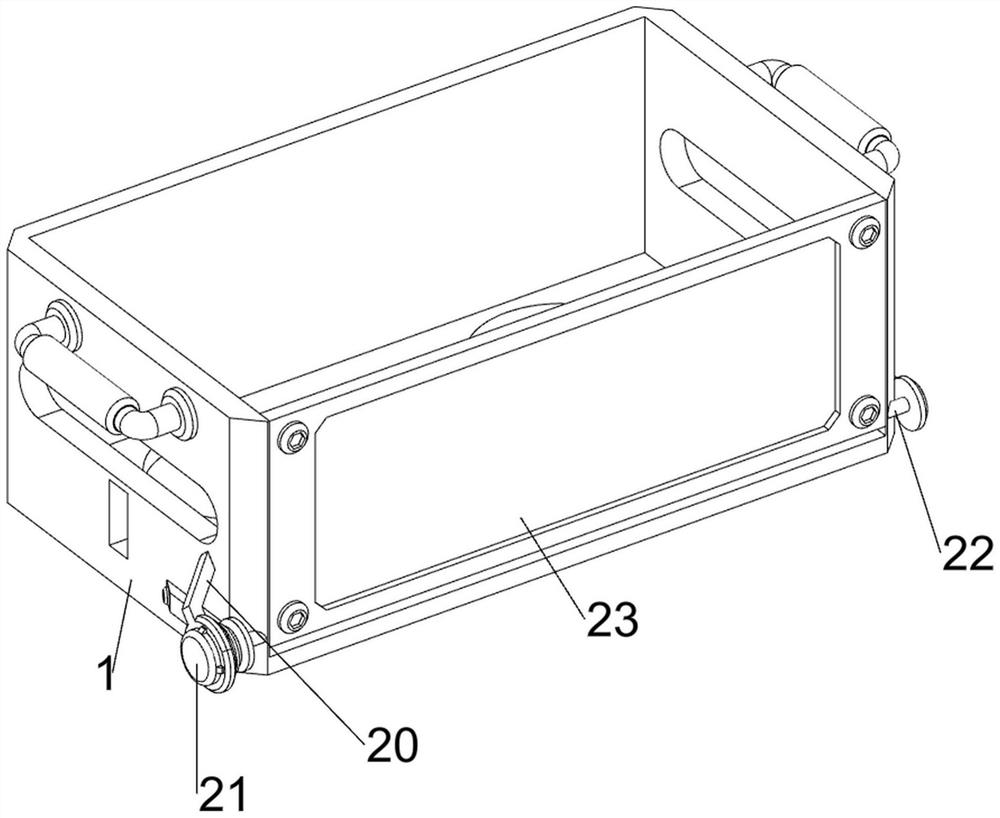

[0031] Such as image 3 As shown, the blocking mechanism 2 includes a support ring 20, a servo motor 21, a first rotating shaft 22 and an opening and closing plate 23. The front part of the lower left side of...

Embodiment 2

[0035] On the basis of Example 1, such as figure 1 and Figure 6As shown, a moving mechanism 4 is also included to facilitate the movement of the loading box 1. The moving mechanism 4 includes a first arc plate 40, a slide rail 41, a sliding plate 42, a first spring 43, a moving plate 44, a mounting rod 45 and Turning wheel 46, the left and right sides of opening and closing plate 23 rear bottoms are all provided with first arc-shaped plate 40 by bolt, and opening and closing plate 23 rotates and drives first arc-shaped plate 40 to rotate, and the left and right sides of loading box 1 inwall are all welded with Slide rail 41, slide rail 41 is all slidingly connected with moving plate 44, and moving plate 44 can move forward and backward on slide rail 41, and moving plate 44 inner side is all provided with sliding plate 42, and moving plate 44 and adjacent slide rail The first spring 43 is arranged between the 41 inner walls, under the action of the first spring 43, it can dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com