Positioning tool and positioning method for resin film melt permeation molding stiffened plate

A positioning tooling and positioning method technology, applied in the field of positioning equipment, can solve problems such as low operating efficiency, achieve the effects of reducing difficulty, reducing labor intensity, and improving positioning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

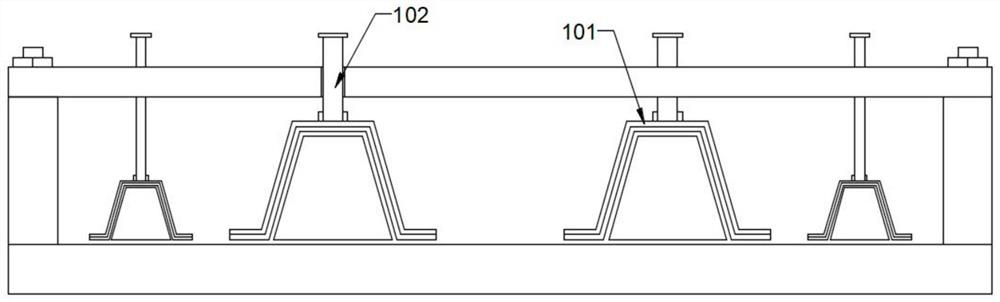

[0040] as attached figure 1 As shown, it is the positioning principle of large-scale hat-shaped reinforced wall panels in the prior art. There are positioning holes on the top of the rib forming mold, and corresponding supporting screws are provided on the gantry. The supporting screws are inserted into the positioning holes to The rib forming mold is fixed, so it is necessary to constantly adjust the position of the rib forming mold in the process of rib positioning to make all the positions of the gantry. The weight of the rib forming mold is as high as 100 kg, and it is hoisted by a crane. The construction time It takes a long time to occupy the crane, consumes a lot of manpower and material resources, the assembly efficiency is low, and the position accuracy of the ribs is not high, the bolt may be installed forcibly, and the accuracy of the position of the ribs seriously affects the stitching of the subsequent ribs and the final The rib position of the formed hat-shaped r...

Embodiment approach 2

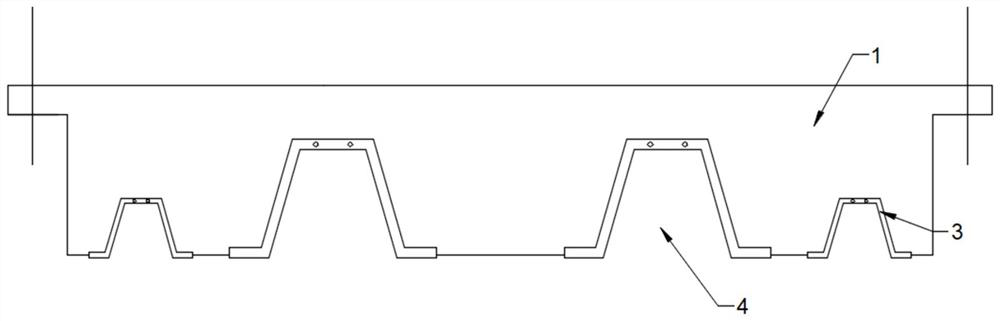

[0048] like Figure 4 As shown, this embodiment, as a preferred embodiment of the present invention, discloses a positioning method for a positioning tool for a resin film melt infiltration molding stiffened plate, which is characterized in that it includes the following steps:

[0049] S1. Arrange the positioning clamps at the installation station in sequence along the axial direction of the ribs;

[0050] According to the positioning accuracy requirements and combined with the actual working conditions of the processing site, first determine the number of positioning clamps;

[0051] Combined with the position of the ribs at the rib assembly station, the shape parameters and position parameters of each positioning groove on the positioning ribs are calculated in advance, and the processing of the corresponding positioning ribs is completed. At the same time, the position of each positioning clamp is fixed, so for It is convenient to quickly and accurately install each posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com