High-precision powder injection mold with locking function

A powder injection, high-precision technology, applied in the field of powder injection, can solve problems such as low operating efficiency, achieve the effect of increasing accuracy, improving accuracy, and stabilizing the locking function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

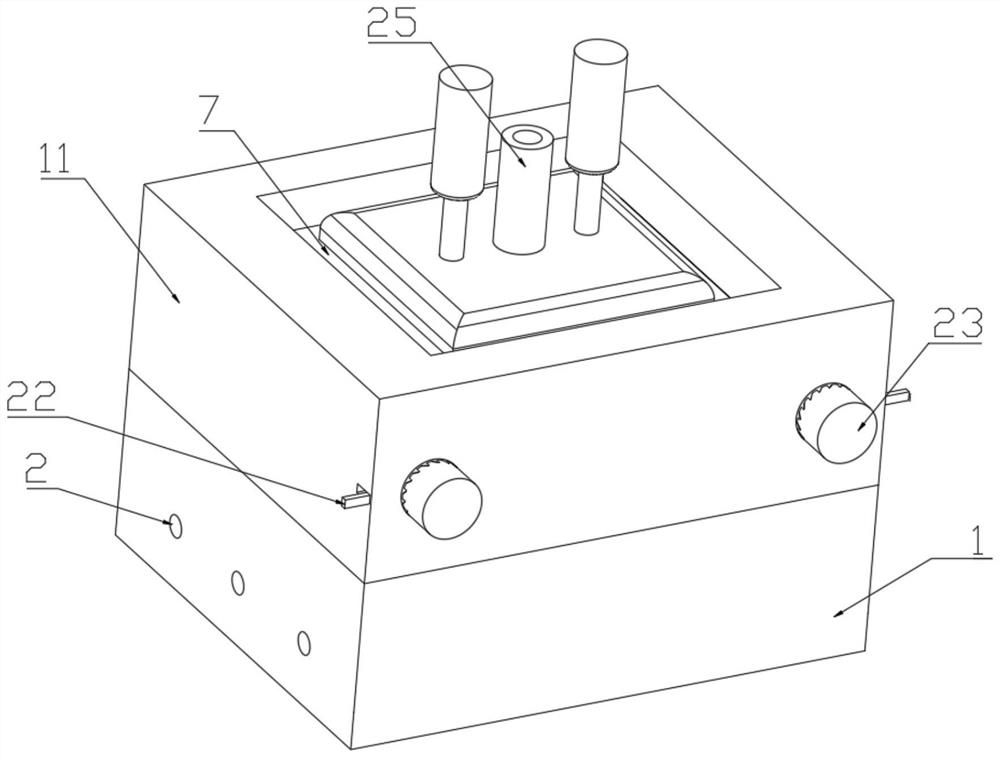

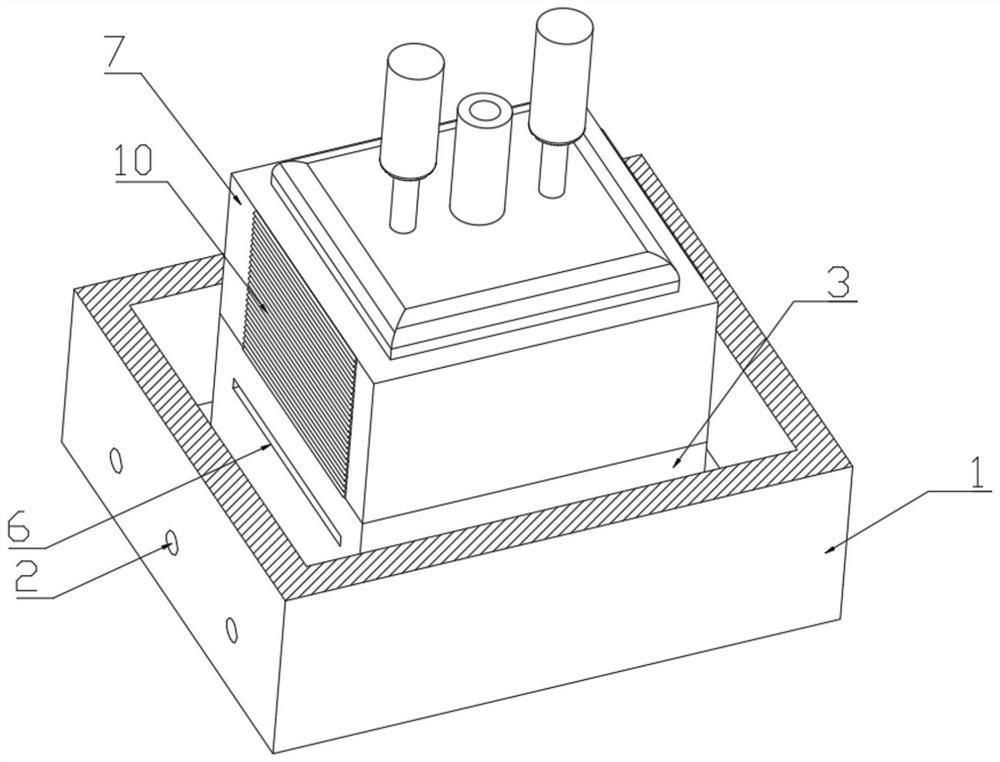

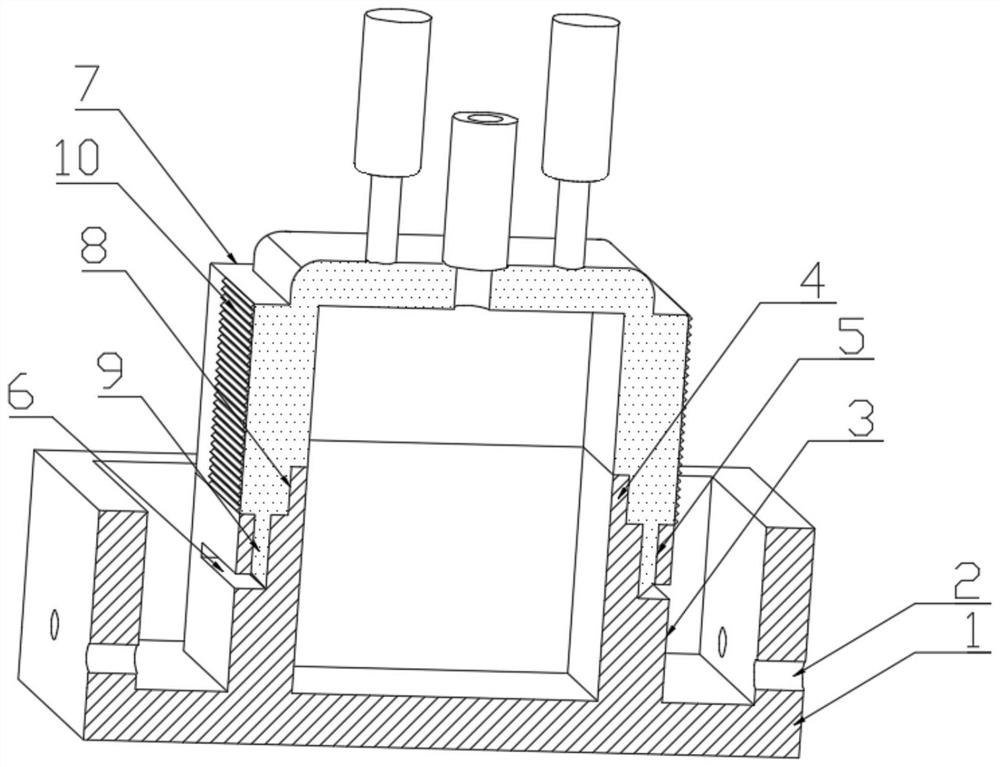

[0029] like Figure 1-6 As shown, a high-precision powder injection mold with a locking function includes a base box 1, a lower mold 3, and an upper mold 7. The bottom of the upper mold 7 is fixedly connected with a pinion 9 inserted into the positioning groove 5 provided on the top of the lower mold 3. Inside, straight teeth 10 are symmetrically installed on both sides of the upper mold 7, and the shaper teeth 9 can be set in a cylindrical or square shape. At the same time, the positioning grooves are set in a groove shape that is installed in conjunction with the shaper teeth 9, to further increase the accuracy of the upper and lower mold installation. A frame-shaped lock installation seat 11 is installed above the base box 1, and a gear 13 meshing with the straight teeth 10 is installed symmetrically on the inner side of the lock installation seat 11. A sliding ring 17 is installed on the inner lock mounting seat 11, and the sliding ring 17 is connected with the lock mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com