Liquid cooling supporting tool for plug-in type connecting pipe and reactor core measuring pipe anti-deformation method

A plug-in, measuring tube technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of core measuring tube deformation, core measuring tube being easily heated, large deformation, etc., and speed up the reduction of weld seam temperature , It is not easy to be deformed by heat, and the effect of avoiding welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

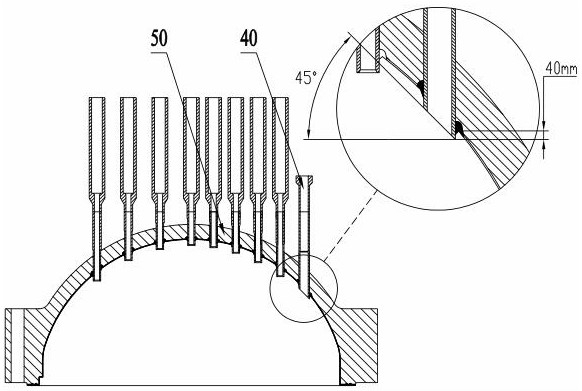

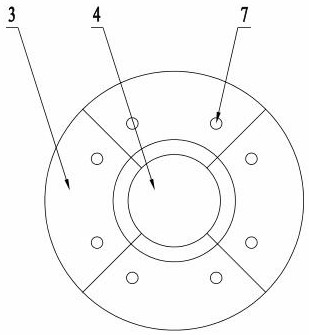

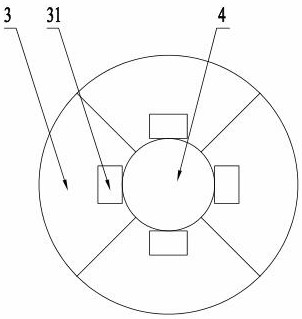

[0045] Such as Figure 2-Figure 9 As shown, the liquid-cooled support tooling for plug-in connection includes a connecting block 1, a strut 2 and four moving rods 3. A number of embedding grooves 11 are arranged on the connecting block 1, and an embedding block 31 is arranged on each moving rod 3. The embedding block 31 is slidably matched with the embedded groove 11, and the four moving rods 3 encircle and form a tapered expansion hole 4. The strut 2 includes a gradual change section 21, a prism section 22 and a thread section 23 arranged coaxially in sequence, and nuts are arranged on the thread section 23. As the adjustment piece 5, the gradual change section 21 of the strut 2 is adapted to the conical expansion hole 4, and the prism section 22 is adapted to the limit hole 12 arranged in the middle of the connecting block 1. By rotating the adjustment piece 5, the strut 2 can be adjusted along the The expansion hole 4 moves axially relative to the expansion hole 4, and the ...

Embodiment 2

[0054] Such as Figure 2-Figure 12 As shown, the structure of the supporting liquid-cooled tooling for tube-sheet welding in this embodiment is the same as that of Embodiment 1, the difference is that the connection block 1 is connected with an extension plate 6, and the extension plate 6 includes a blocking portion, and the blocking portion It can be blocked in the moving direction of the adjustment member 5 .

[0055] In the supporting liquid-cooled tooling for tube sheet welding in this embodiment, an extension plate 6 is provided on the connection block 1. The extension plate 6 is preferably L-shaped. After the extension plate 6 is connected to the connection block 1, one of the sides can be blocked by the adjustment member 5 In the direction of movement, the extension plate 6 is used to assist in limiting the relative movement direction of the strut 2 and the expansion hole 4 .

[0056] Specifically, the extension board 6 includes a first board body, a second board body ...

Embodiment 3

[0059] Such as Figure 2-Figure 12 As shown, the structure of the liquid-cooled supporting tool for plug-in connection of this embodiment is the same as that of Embodiment 1 or Embodiment 2, the difference is that each moving rod 3 is respectively provided with a liquid flow channel 7, and each liquid flow channel 7 is respectively Connected to the liquid supply mechanism 8 , temperature detection devices are installed on the inlet and outlet sides of each liquid flow channel 7 , and all temperature detection devices are connected to the controller 9 by communication, and the controller 9 is electrically connected to the liquid supply mechanism 8 .

[0060] In the liquid-cooled support tooling for plug-in connection of this embodiment, the liquid flow channel 7 includes a liquid inlet flow channel 71, a liquid outlet flow channel 72 and a communication flow channel 73, and the liquid inlet flow channel 71 and the liquid outlet flow channel 72 move along the moving rod 3 The le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com