Pipeline small defect axial length detection method and application thereof

A technology of axial length and detection method, which is applied in the processing of detection response signals, measuring devices, and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc. It can solve difficult to extract defect signals, local optimal and global convergence probability of differential evolution algorithm Low-level problems, to achieve fast propagation speed, realize the health status assessment of pipeline ultrasonic guided wave detection and diagnosis, and solve the effect of quantitative identification problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute a conflict with each other.

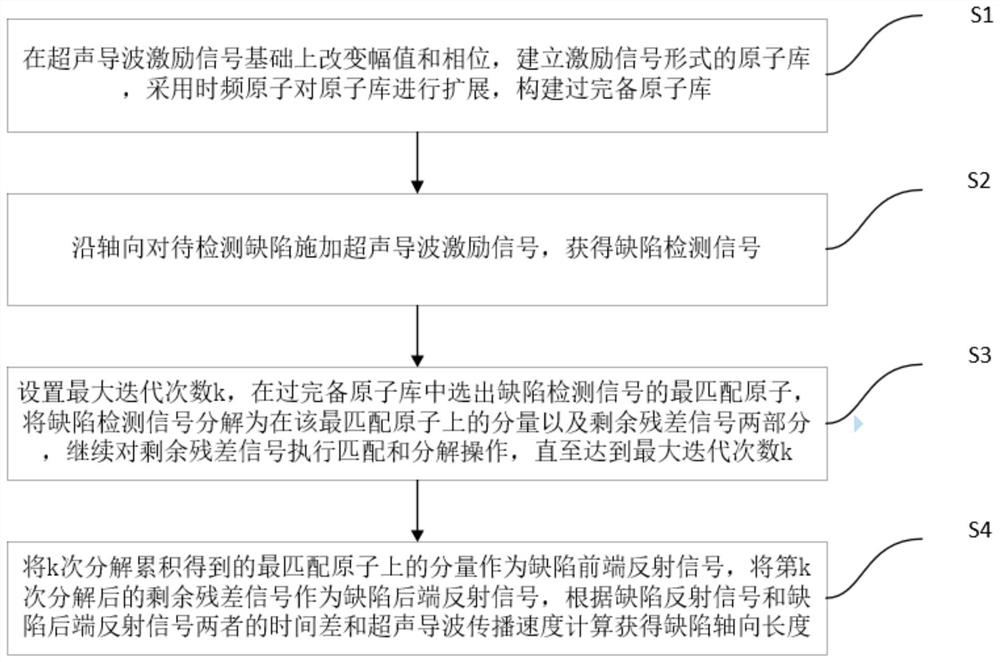

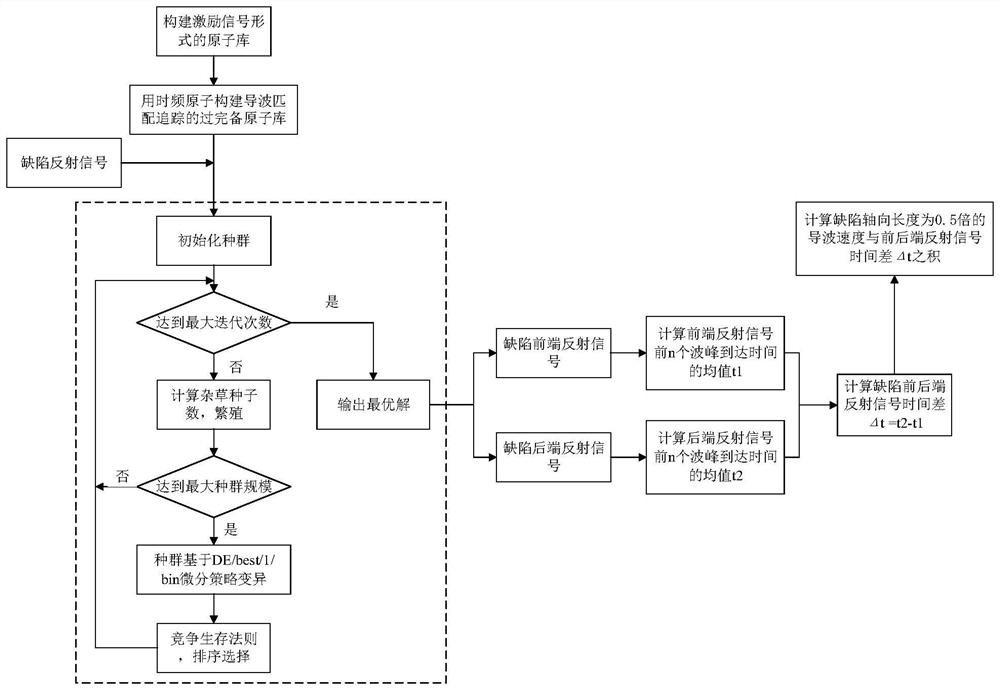

[0050] Such as figure 1 As shown, a method for detecting the axial length of a small pipeline defect in an embodiment of the present invention includes steps:

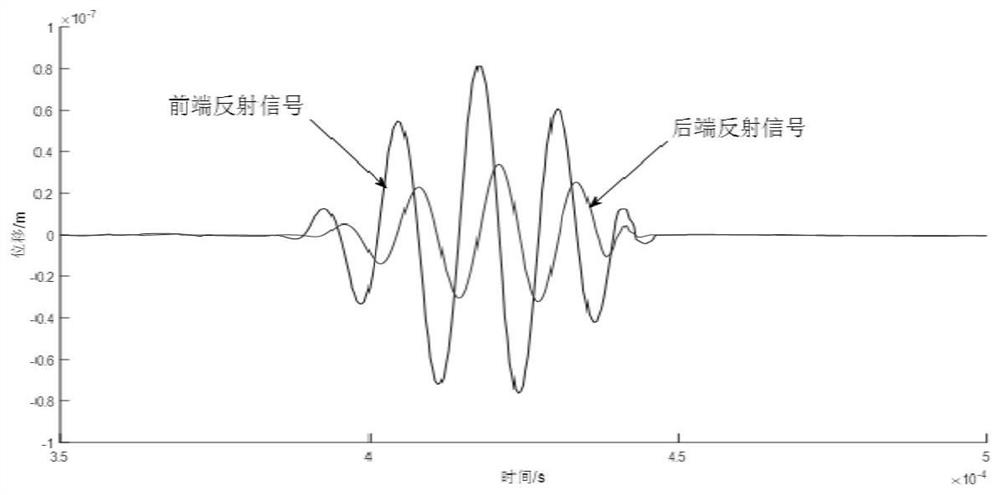

[0051] S1, change the amplitude and phase on the basis of the ultrasonic guided wave excitation signal, establish an atomic library in the form of the excitation signal, expand the atomic library by using time-frequency atoms, and constr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com