Servo driver switching power supply

A servo drive, switching power supply technology, applied in electrical components, springs/shock absorbers, vibration suppression adjustment, etc., can solve problems such as increasing device downtime, reducing device functionality, increasing workload, etc., to avoid damage to precision components , Improve the service life and reduce the effect of downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing:

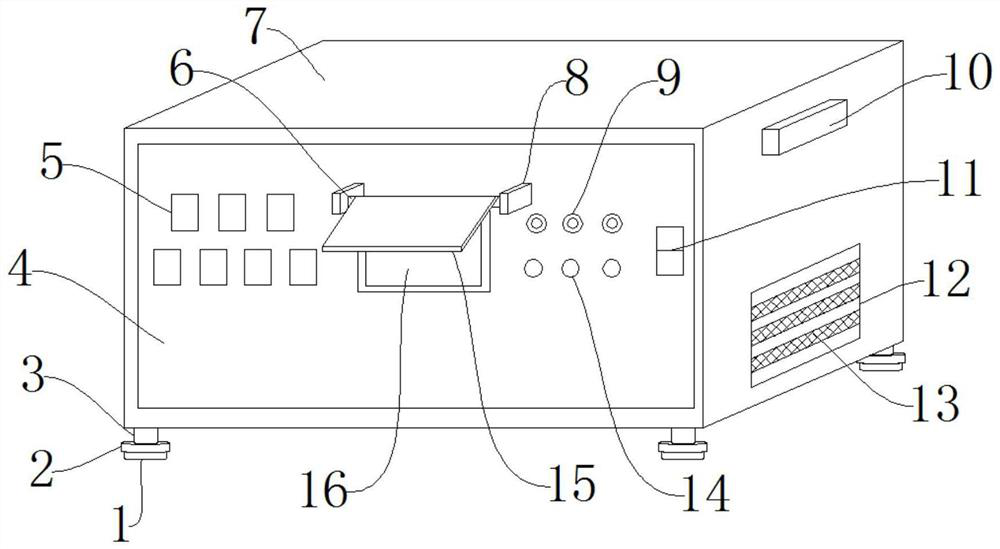

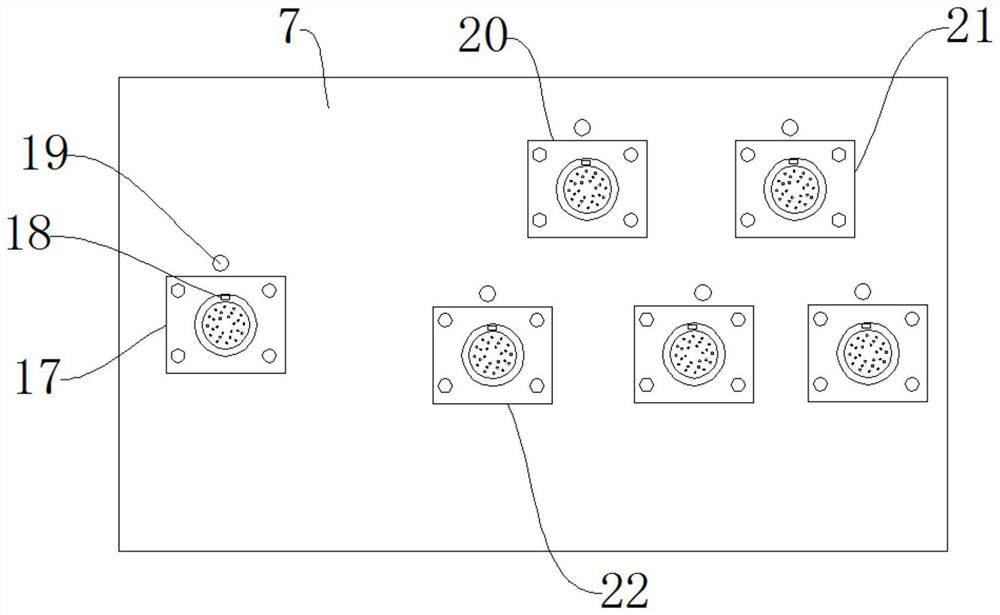

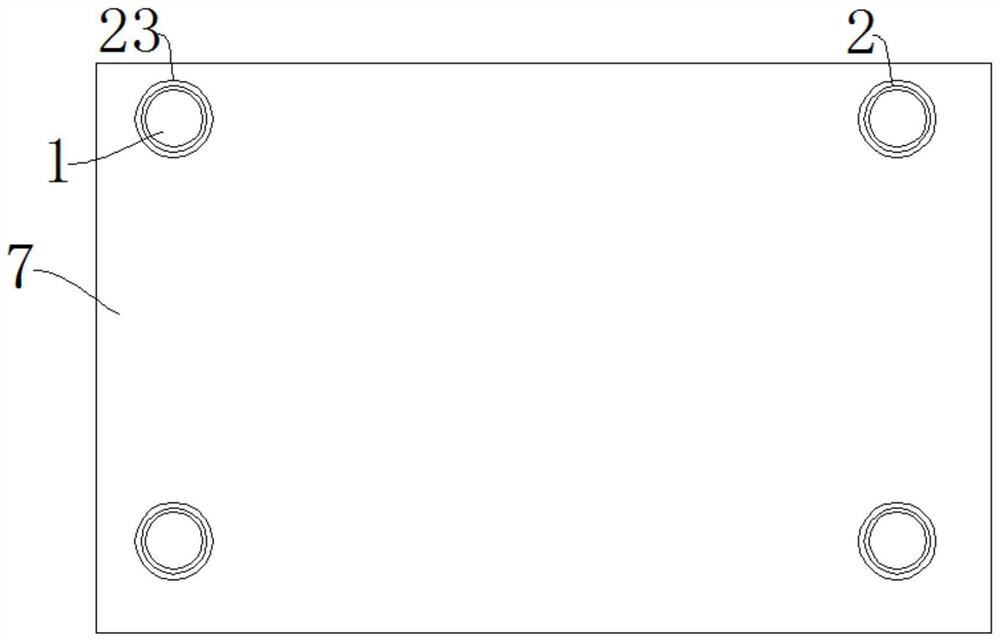

[0037] like Figure 1-Figure 4As shown, a switching power supply for a servo drive includes a power supply body 7, a bump 10, a telescopic column 3 and a spring 24. The bumps 10 are fixed on both side walls of the power supply body 7, and the bottom of the power supply body 7 Sleeves 23 are arranged at the four corners of the end, the telescopic column 3 is fixed inside the sleeve 23, the spring 24 is fixed on the outer wall of the telescopic column 3, and the bottom end of the telescopic column 3 is provided with a backing plate 2. A suction cup 1 is fixed at the bottom of the backing plate 2, an input interface 17 is arranged on the back wall of the power supply body 7, an output interface 22 is arranged on one side of the input interface 17, and a signal is arranged above the output interface 22. Interface 20, the signal interface 20 side is provided with a network inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com