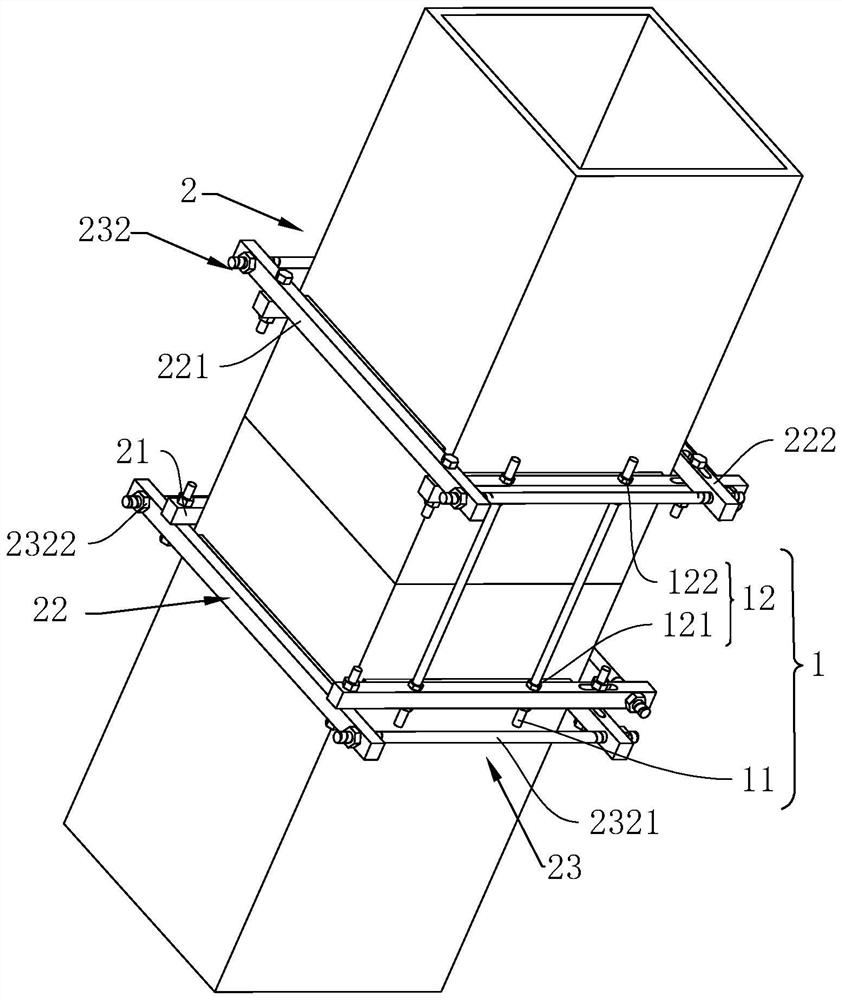

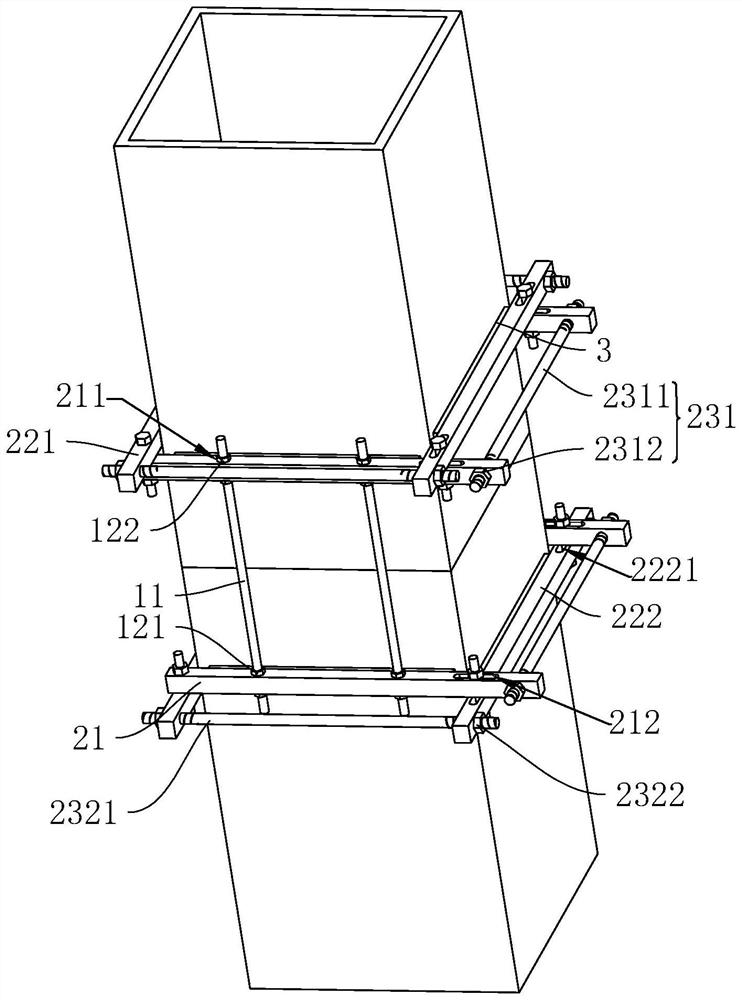

Steel column connection perpendicularity regulator

A verticality and adjuster technology, applied in the directions of columns, piers, pillars, etc., can solve the problems of cumbersome procedures, increase construction time, affect construction period, etc., and achieve the effect of reducing skew, shortening construction time, and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

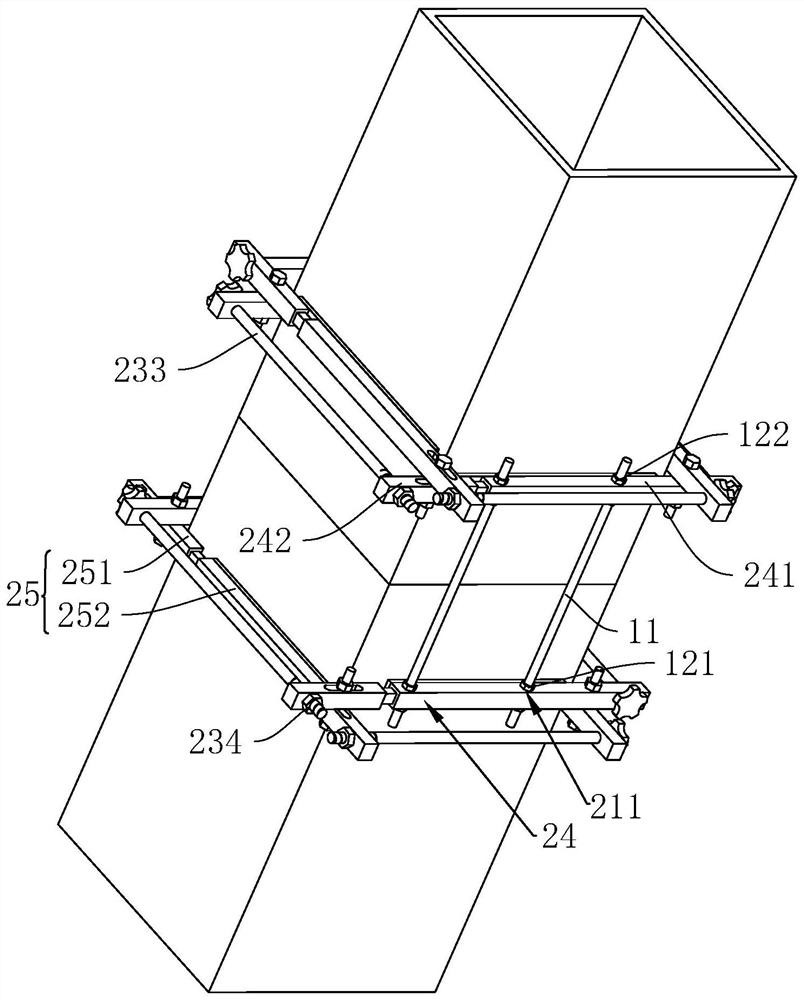

Embodiment 2

[0043] reference Figure 3 , the difference from embodiment 1 is that the fixing device 2 includes two first support rods 24 and two second support rods 25. The first support rod 24 and the second support rod 25 are bonded with an anti-skid cushion block 3 near the side of the steel column. In this embodiment, the anti-skid cushion block 3 is made of rubber material, both ends of the first support rod 24 are connected with the second support rod 25 through bolts, the first support rod 24 includes a fixed section 241 and a sliding section 242, and the sliding section 242 is slidably connected with the fixed section 241, One end of the sliding section 242 away from the fixed section 241 is provided with a fixing hole 2421. In this embodiment, the fixing hole 2421 is set as a waist hole, the length direction of the fixing hole 2421 is set along the axial direction of the first support rod 24, the second support rod 25 includes a connecting section 251 and a telescopic section 252, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com