Pneumatic rigidity-variable soft gripper

A variable stiffness, soft finger technology, applied in the field of capture, can solve the problems of poor capture performance, limited capture objects, and limited capture objects, and achieve good envelopment, increased load capacity, and envelope Good performance and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

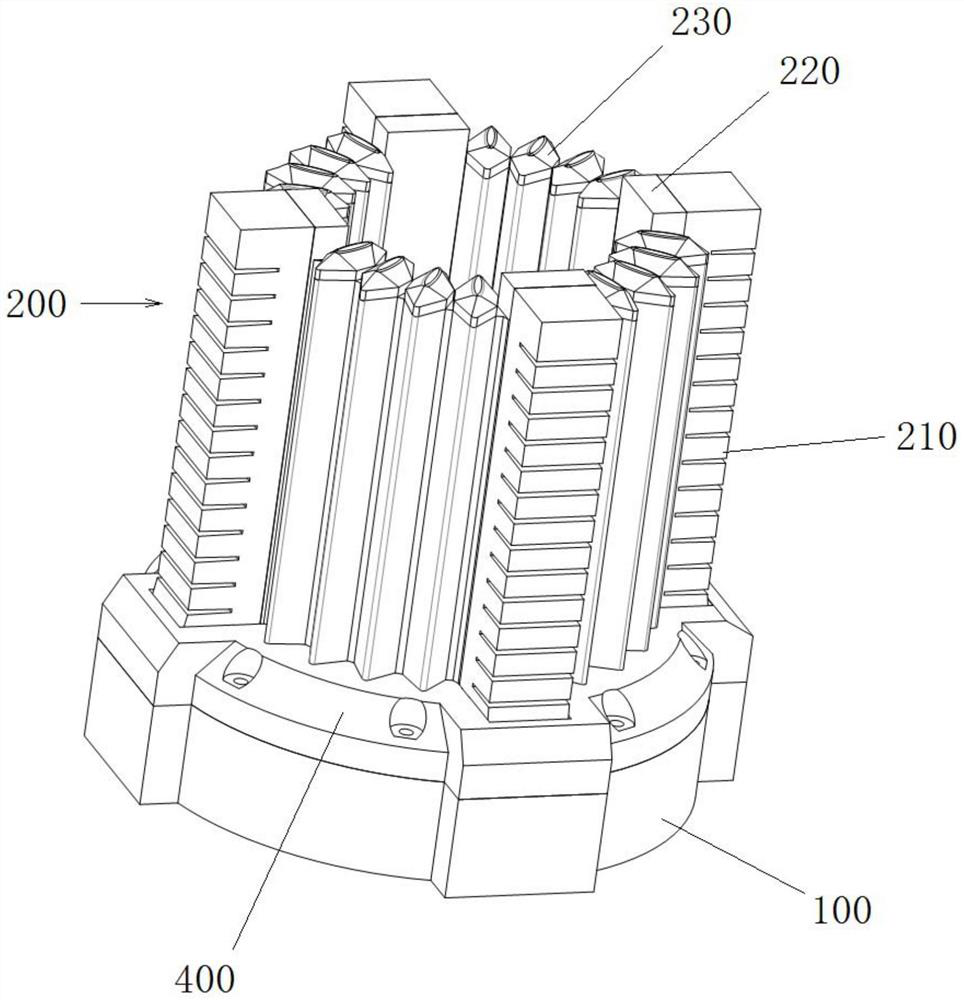

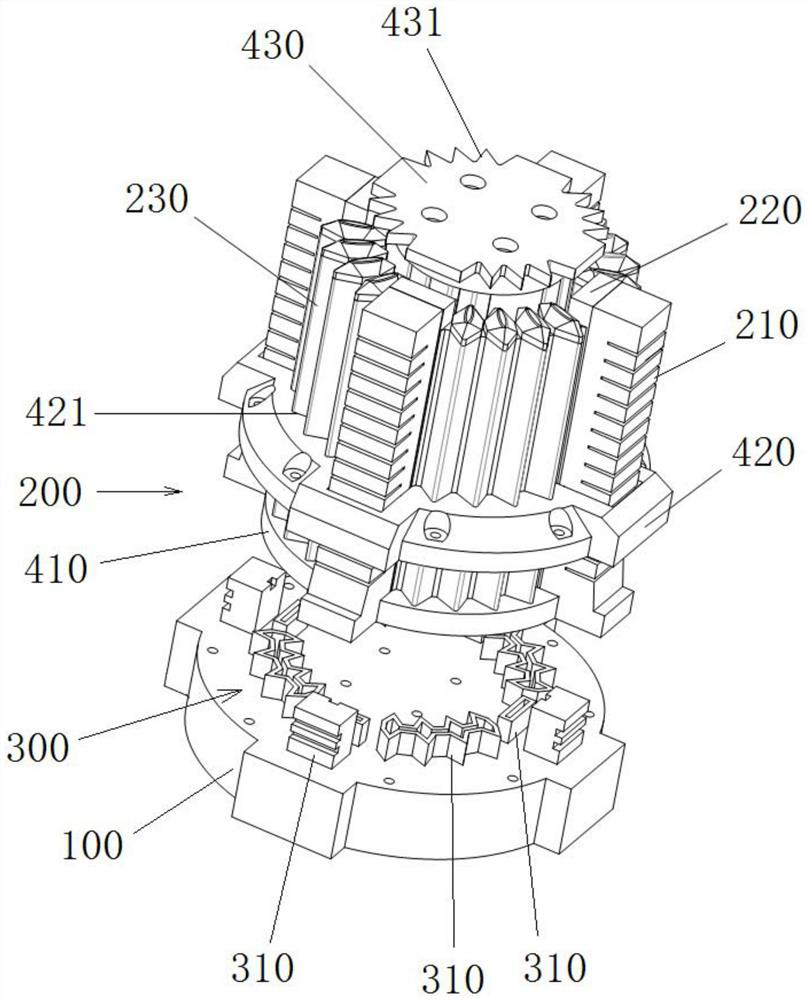

[0030] This embodiment provides a soft gripper with pneumatically variable stiffness, such as Figure 1-5 As shown, the soft gripper includes a base 100 , a software execution part 200 and an air distribution part 300 disposed on the base 100 .

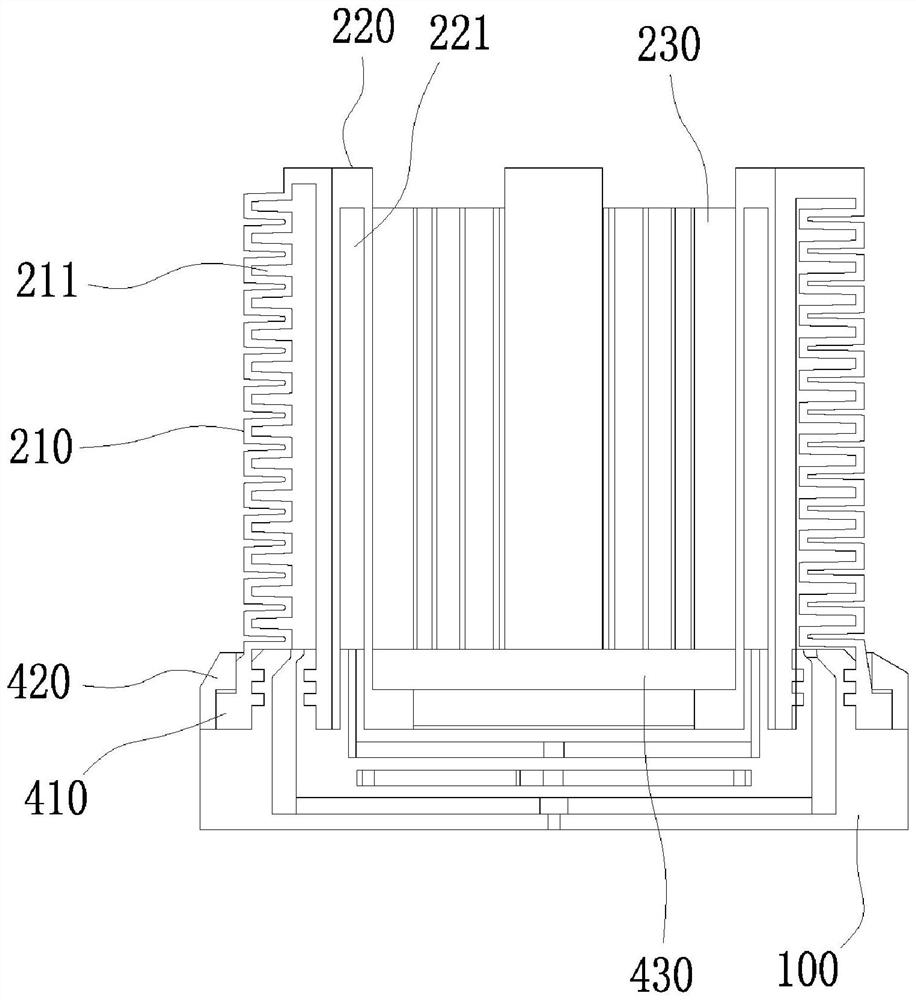

[0031] Such as figure 1 As shown, the software execution part 200 is in the shape of a cylinder, and its interior is a hollow structure; the software execution part 200 includes four pneumatic soft fingers 210 uniformly arranged around the circumference, and a variable stiffness soft part arranged on the pneumatic soft fingers 210 along the radial direction. 220 and the connecting software part 230 connected to the two pneumatic soft fingers 210.

[0032] Specifically, the variable stiffness soft body part 220 is parallel to the pneumatic soft finger 210 in the axial direction, and the connecting soft body part 230 in the circumferential direction has an accordion-shaped structure;

[0033] Wherein the pneumatic soft finger 210 has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com