Simulation operation inspection robot for electric power operation inspection

An inspection robot and electric power technology, which is applied to manipulators, manufacturing tools, etc., can solve the problems of reduced force inspection robot operation stability, lack of stable auxiliary structures, and prone to overturning, etc., to improve environmental adaptability and use safety. Sex, the effect of increasing buoyancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

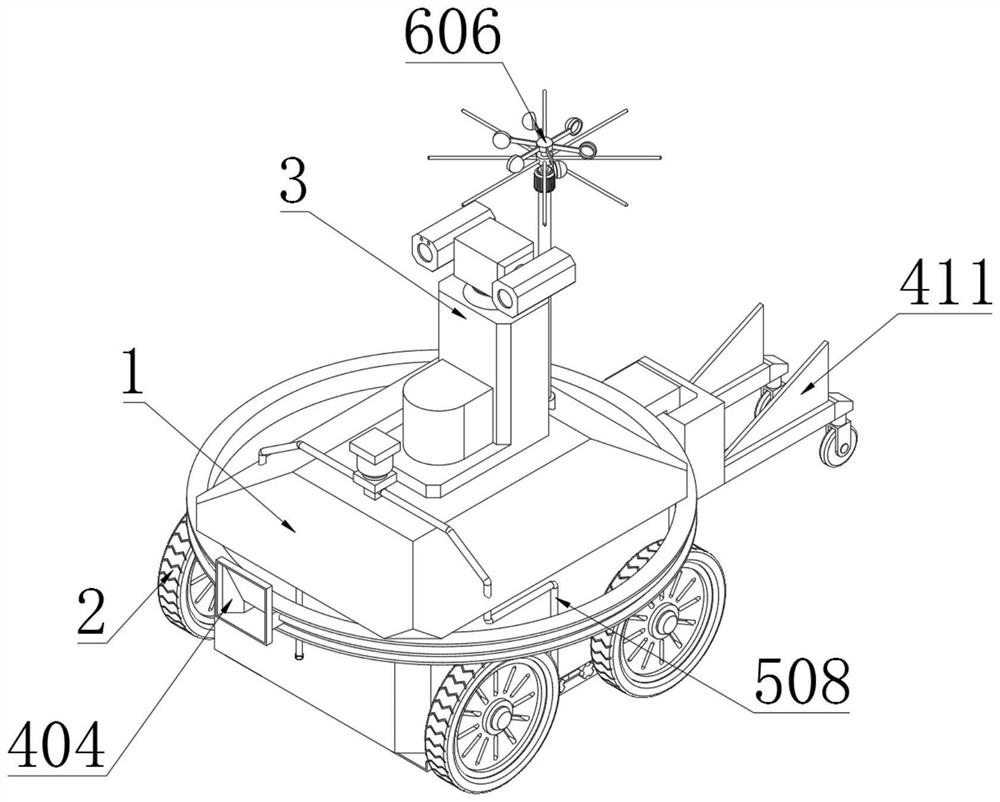

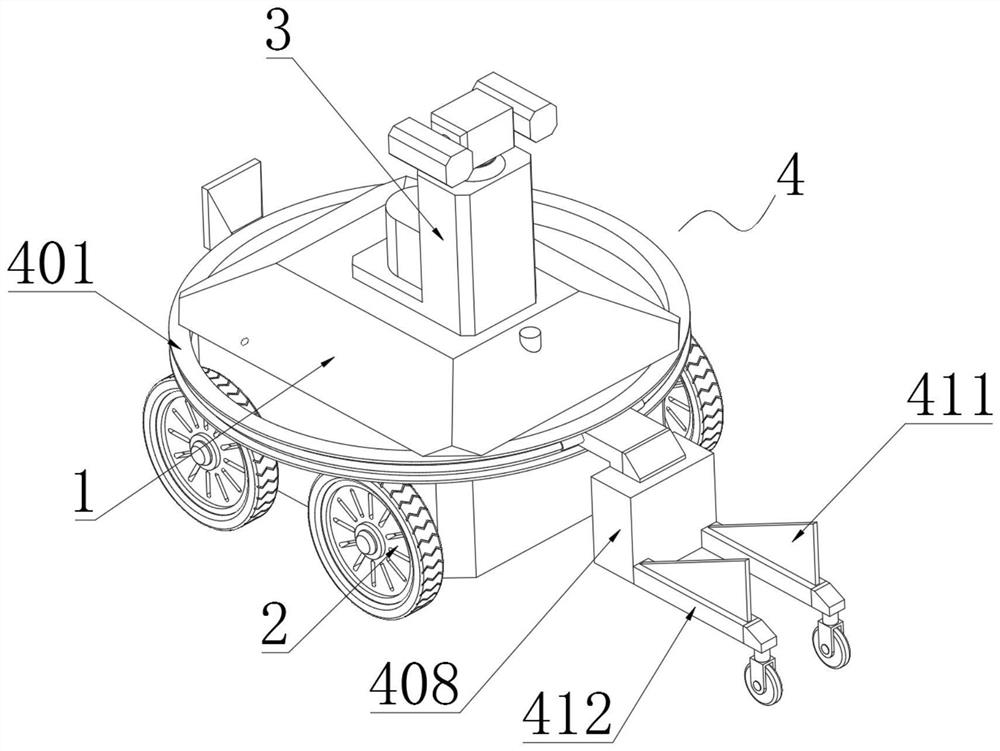

[0047] Example: such as Figure 1-7 As shown, the present invention provides a technical solution, a simulation operation inspection robot for electric power inspection, including an inspection robot main body 1, driving rollers 2 are arranged at both ends of the bottom of the inspection robot main body 1, and the inspection robot An active camera 3 is arranged in the middle of the top of the main body 1;

[0048] The outer side of the main body 1 of the inspection robot is provided with a rotating extension support mechanism 4;

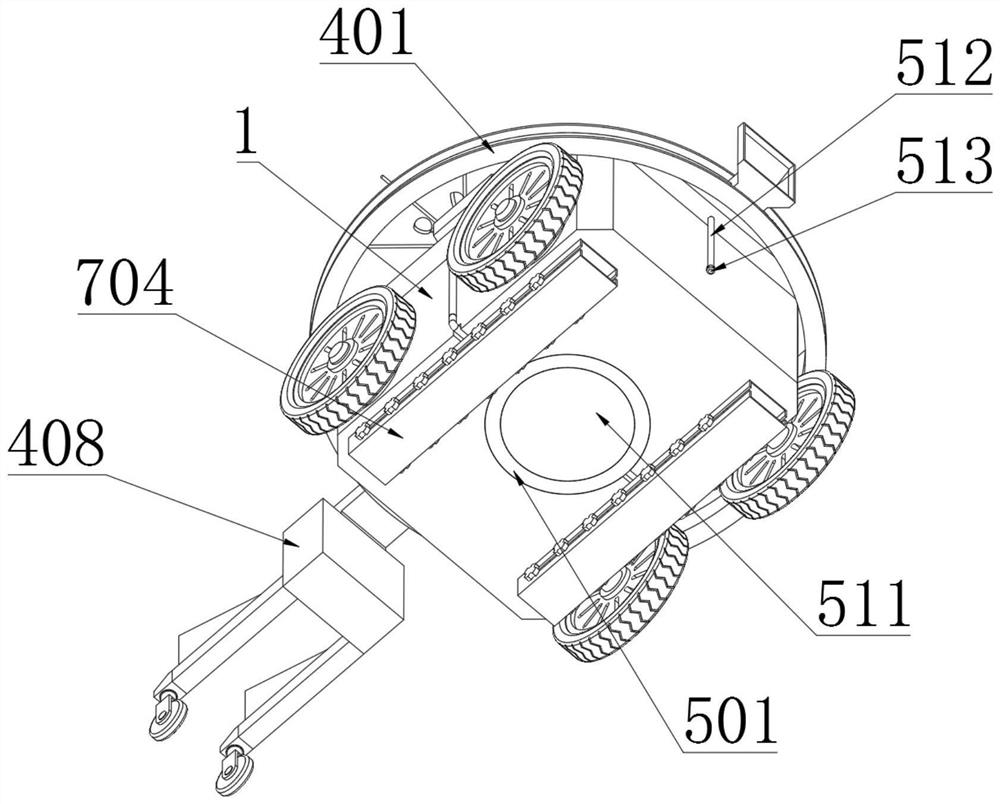

[0049] The rotating and extending support mechanism 4 includes installing a circular rail 401, installing an inner ring 402, installing a front box 403, collecting air box 404, air guide elbow 405, one-way air valve 406, air guide tail box 407, liquid storage tail box 408, Squeeze slide plate 409, support flat pipe 410, guide tail plate 411, support sliding bar 412, elastic traction rope 413, install inclined block 414 and rotating roller 415;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com