Chemical production multi-tower adsorption accumulative error elimination method and system and storage medium

A technology for chemical production and cumulative error, applied in chemical instruments and methods, separation methods, solid adsorbent liquid separation, etc., can solve problems affecting chemical purification efficiency, reduce the probability of uncertain adsorption time, and improve production efficiency , the effect of reducing the probability of cumulative error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

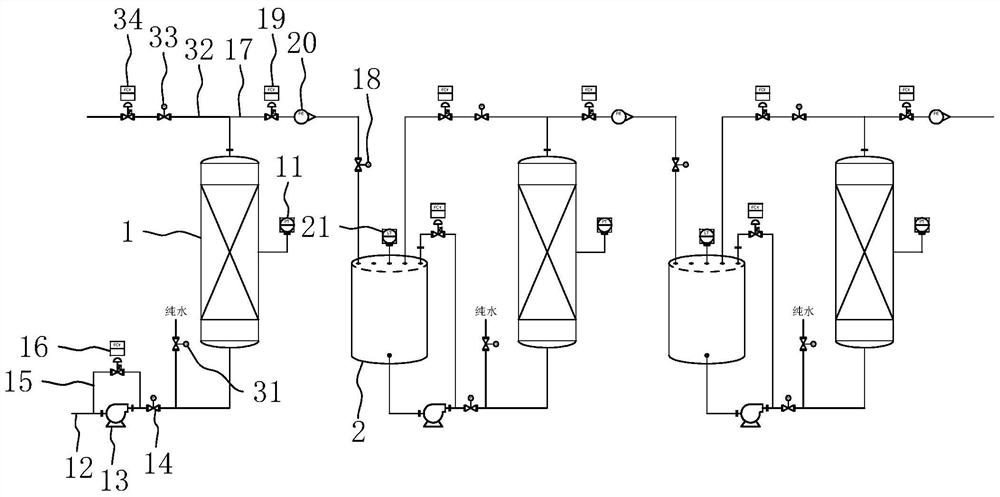

[0042] The following is attached Figure 1-2 The application is described in further detail.

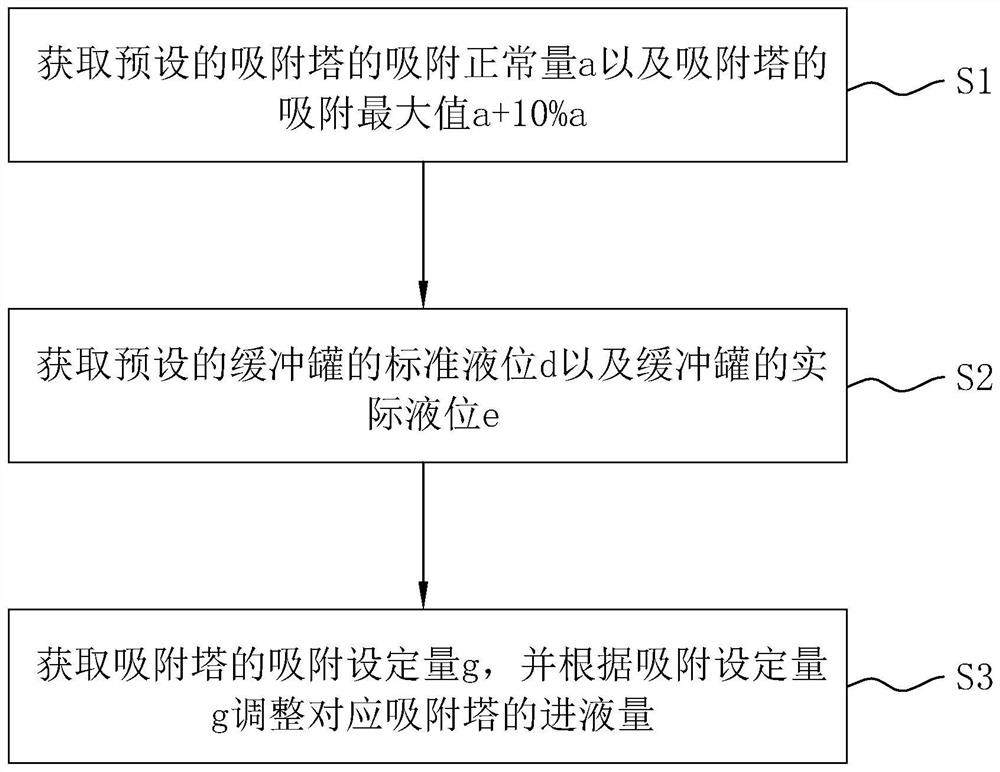

[0043] The embodiment of the present application discloses a method for eliminating cumulative errors of multi-tower adsorption in chemical production. refer to figure 1 , including the following steps:

[0044] S1. Obtain the preset normal adsorption amount a of the adsorption tower and the maximum adsorption value a+10%*a of the adsorption tower;

[0045] It should be noted that when the amount of liquid adsorption in the adsorption tower is less than the normal amount of adsorption a, the adsorption tower is convenient for completely adsorbing the liquid; When the difference between the normal quantities a is less than the adsorption tolerance, the adsorption tower can still completely absorb the liquid. When the amount of liquid adsorption in the adsorption tower is greater than the maximum adsorption value a+10%*a, the liquid cannot be completely absorbed by the adsorption t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com