Electronic cigarette and control method thereof

A control method and technology for electronic cigarettes, which are applied in the directions of tobacco, smoker's products, applications, etc., can solve the problem that the atomizer cannot find the taste suitable for atomization, and achieve the effect of satisfying the taste of atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

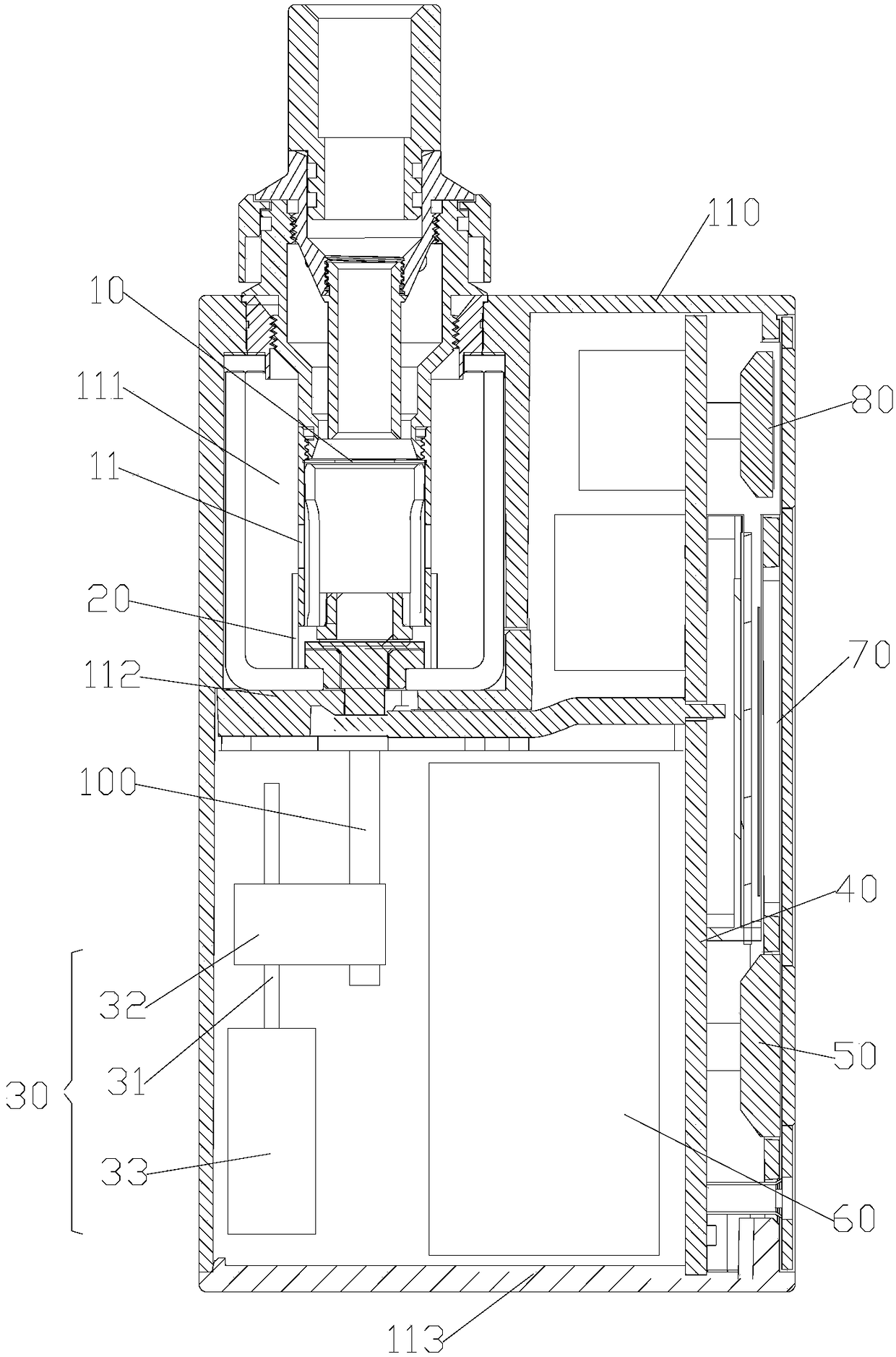

[0036] like figure 1 As shown, in this embodiment, the liquid inlet control member 20 is a sleeve structure, and the sleeve structure is sleeved on the outside of the atomizing head 10 . The sleeve structure cooperates with the liquid inlet 11 of the atomizing head 10 to realize the control of the liquid inlet.

[0037] In this embodiment, the liquid intake volume is controlled through the rotation of the liquid intake control member 20 .

[0038]Specifically, the atomizing head 10 is fixed, and the driving mechanism 30 drives the liquid inlet control member 20 to rotate. The liquid inlet control member 20 is provided with a liquid outlet 21, and the liquid outlet 21 is opened on the side wall of the sleeve structure. When the driving mechanism 30 drives the liquid inlet control part 20 to rotate, by adjusting the overlapping area of the liquid inlet 21 and the liquid inlet 11, the effective passage area is adjusted, and then the adjustment of the liquid inlet of the electr...

Embodiment 2

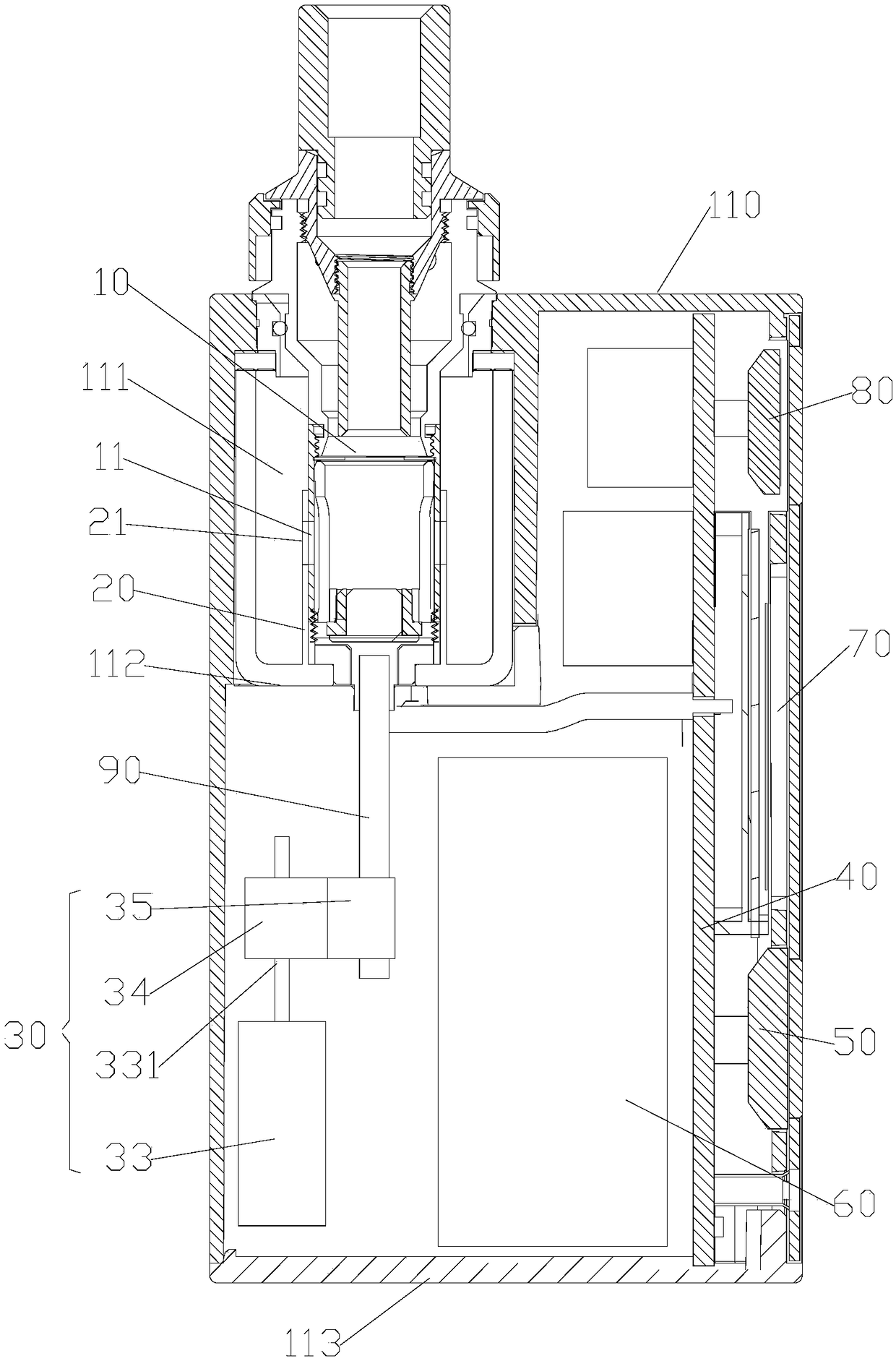

[0049] The difference from Embodiment 1 is that the liquid inlet control member 20 moves linearly along the axis of the atomizing head 10 instead of rotating. The specific structure of the driving mechanism 30 is different.

[0050] like figure 2 As shown, specifically, the atomizing head 10 is fixed, and the driving mechanism 30 drives the liquid inlet control member 20 to move linearly along the axial direction of the atomizing head 10 to cover or give way to the liquid inlet 11 of the atomizing head 10, so as to The effective passing area of the liquid inlet 11 of the atomizing head 10 is adjusted.

[0051] At this time, there is no need to specially provide the liquid outlet 21 . Because when the liquid inlet control member 20 moves to a position staggered from the liquid inlet 11, the liquid inlet 11 is naturally exposed, and the relative position between the liquid inlet control member 20 and the control liquid inlet 11 can make the liquid inlet 11 is fully occlude...

Embodiment 3

[0057] The difference from Embodiment 1 is that the atomizing head 10 rotates and the liquid inlet control member 20 is fixed.

[0058] like image 3 As shown, specifically, the liquid inlet control member 20 is fixed, the driving mechanism 30 drives the atomizing head 10 to rotate, and the liquid inlet control member 20 may be provided with a liquid outlet 21 . At this time, if the liquid inlet control member 20 is a sleeve structure, in order to ensure that the effective passage area of the liquid inlet 11 of the atomizing head 10 can be adjusted, a liquid inlet 21 needs to be provided on the liquid inlet control member 20 . At this time, the atomizing head 10 is driven to rotate by the driving mechanism 30, and the overlapping area between the liquid inlet 21 on the liquid inlet control member 20 and the liquid inlet 11 of the atomizing head 10 is adjusted, thereby changing the progress of the atomizing head 10. The effective passage area of the liquid port 11 can furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com