Advanced modular model for training dental operation hand feeling

An operating feel and modular technology, applied in the field of dental training models, can solve the problems of large gap in feel, unfavorable control of stable control of horizontal and vertical fine operations, and unsimulated hardness of teeth at different levels, so as to improve training effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0039] Embodiment 2, a method for using an advanced modular model for training dental operation feeling, comprising the following steps;

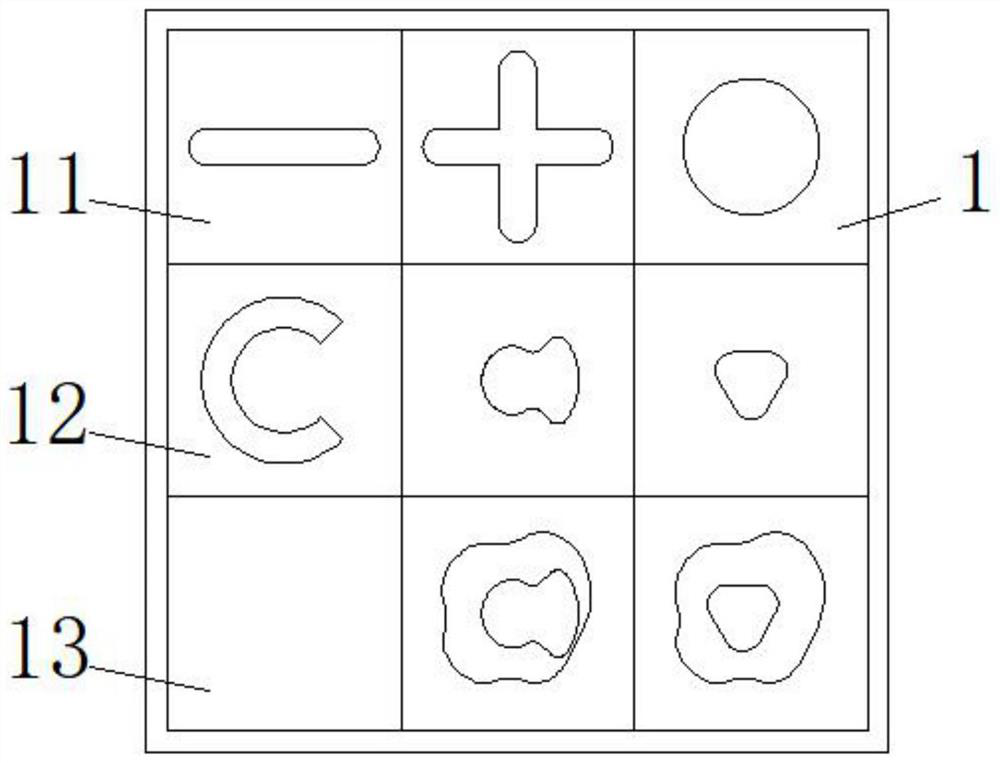

[0040] S1. First, train through the one-shaped training structure and the cross-shaped training structure on the nine-square grid structure on the model main body 1, and exercise the fine motor training of the student's hand level in one direction;

[0041] S2, through the circular training structure and the C-shaped training structure on the nine-square grid structure on the model main body 1, train the students' hand multi-directional arc fine movement training;

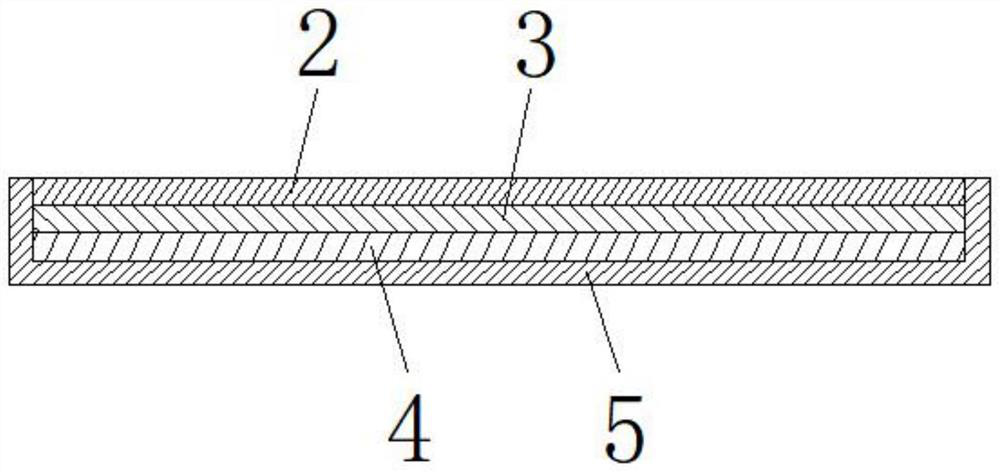

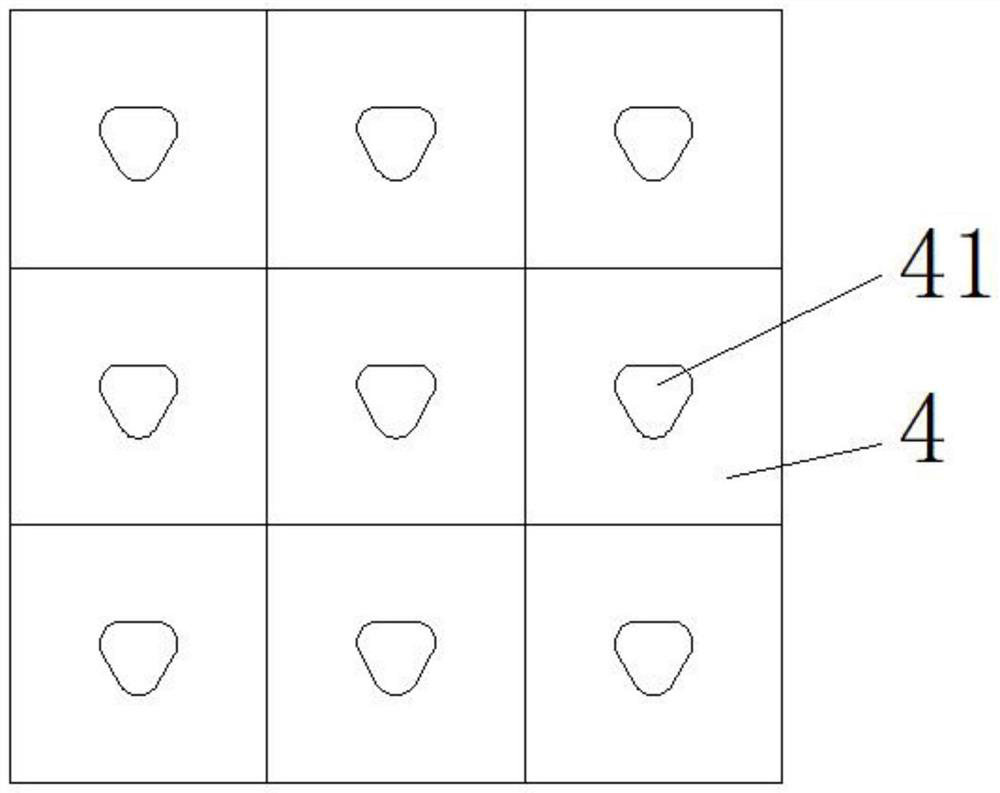

[0042] S3. Through the training structure of different depths of circular triangles on the upper pulp cavity layer 4 of the model main body 1 and the nine-square grid structure, train students' comprehensive fine motor skills in the horizontal and vertical directions;

[0043] S4. Through the two tooth surface areas on the nine-square grid structure on the model main body 1, fin...

experiment example

[0045] As an experimental example, the advanced modular model used to train the dental operation feel in Example 1 was applied to the second-year undergraduate training class for fine hand movement training. The questionnaire showed that 86.84% of the students liked it very much. A fine motor training model, 97.4% of the students think that this fine operation model is helpful for clinical operation, can exercise their fine motor, more than 98.3% of the students feel the sense of failure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com