Sampling device for liquid food detection

A sampling device, liquid food technology, applied in the direction of sampling devices, etc., can solve the problem of not being able to complete the sampling of multiple deep samples in sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

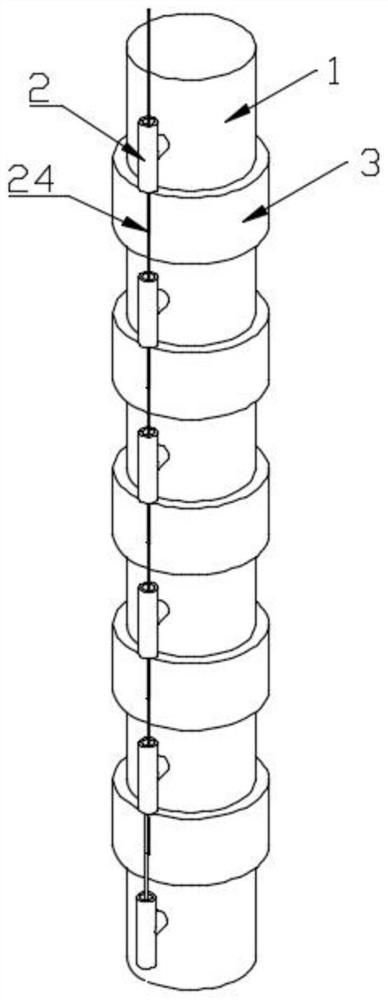

[0027] Such as figure 1 , a sampling device for liquid food detection, comprising six samplers 1 sequentially connected through the connector 3; The body 101 is threaded, and one side of the sampler 1 is provided with an opening 11, and the opening 11 is connected with a first liquid inlet pipe 12, and the first liquid inlet pipe 12 is inclined upward, and its axial direction is the same as that of the sampler 1. The included angle of the direction is 85°, and the end of the first liquid inlet pipe 12 is connected with the second liquid inlet pipe 2 whose axial direction is the same as that of the sampler 1; the second liquid inlet pipe 2 is provided with a sliding piston Assembly, the piston assembly includes an upper piston 21, a lower piston 22, and a connecting rod 23 connected between the upper piston 21 and the lower piston 22; a traction structure 24 is connected between two adjacent piston assemblies.

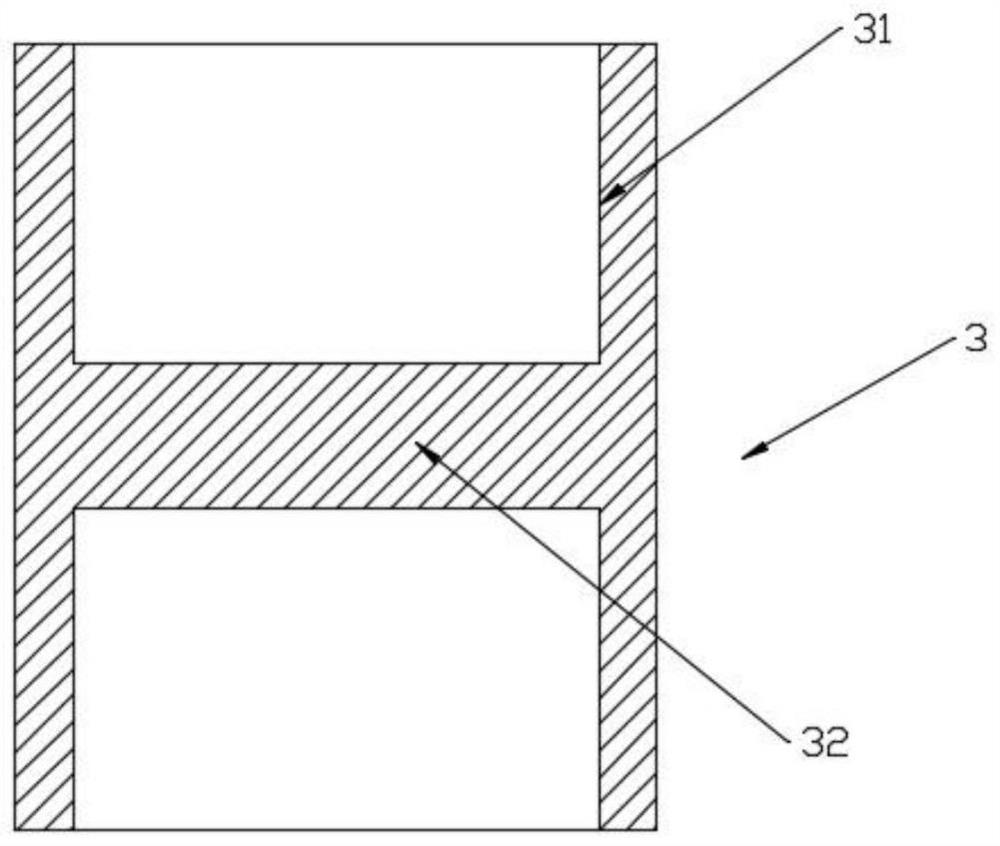

[0028] Such as figure 2 , the connector 3 includes a pipe sleev...

Embodiment 2

[0031] Implement 2, differ from embodiment 1 in that; as image 3 ;

[0032] The sampler 1 is provided with two openings 11, and the axial directions of the two openings 11 are the same; and the central axes of the two first liquid inlet pipes 12 located on the same sampler 1 are coplanar; the first liquid inlet pipes 12 are inclined upward, and The included angle with the axial direction of the sampler 1 is 85°; through two openings 11, and two liquid inlet structures composed of the first liquid inlet pipe 12 and the second liquid inlet pipe 2, it is convenient to discharge the sample while sampling Air inside device 1.

Embodiment 3

[0033] Embodiment 3, on the basis of Embodiment 1 and 2, carry out in order to facilitate the control of the overall sampling, and facilitate the manipulation of the sampling device;

[0034] Such as Figure 7 with 8 A handle 4 is connected and arranged on a sampler 1 located at the top, and the handle 4 includes a handle bar 41 of U-shaped structure. A set of fixed sleeves 43 arranged on the outer peripheral side of the sampler 1 is connected between them; the handle 4 is also provided with a lifting mechanism 5 including two elastic telescopic structures 44, a cross bar 45 and a control component 46;

[0035] The pulling mechanism 5 is provided with a movable rod 47 connected to the traction structure 24 on the top sampler 1 and controlling the piston assembly to move upward along the length direction of the second liquid inlet pipe 2; two elastic telescopic structures 44 are respectively provided On the upper surfaces of the two connecting plates 42; the cross bar 45 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com