Novel anti-seismic steel structure

An anti-seismic steel, a new type of technology, applied in the direction of anti-seismic, building types, building components, etc., can solve the problems of loose seismic steel structure, structural looseness, and large limitations of seismic structure, so as to protect its own structure and solve the effect of structural looseness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

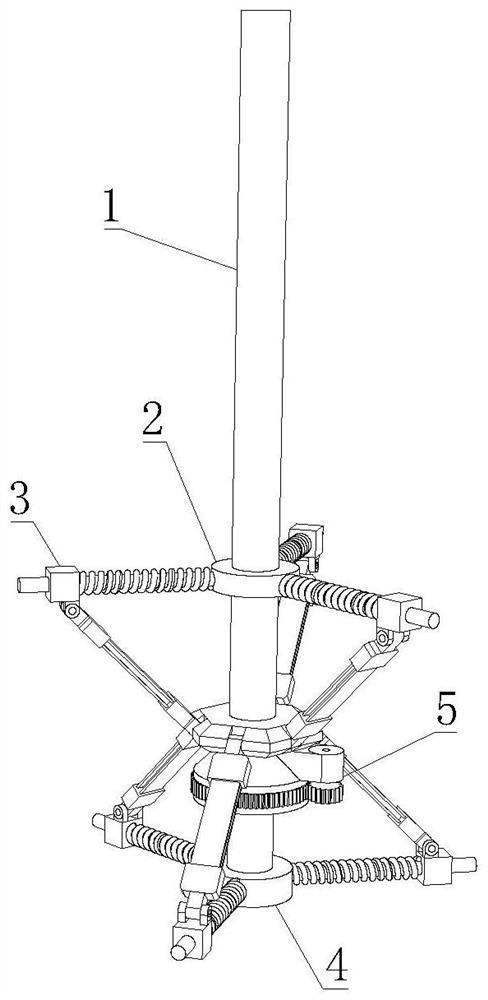

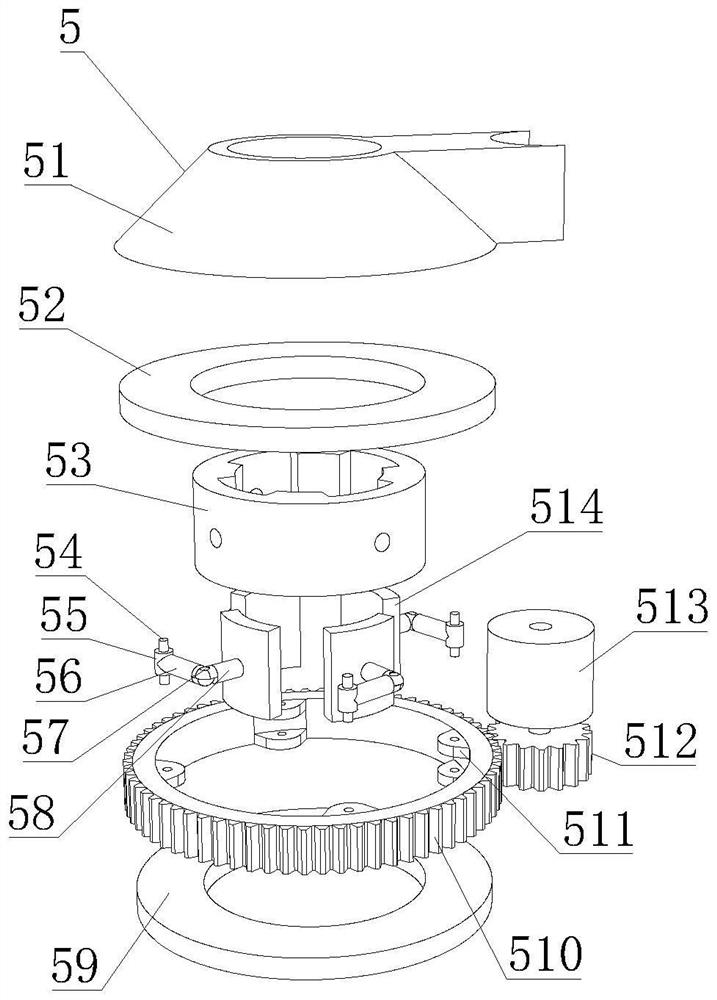

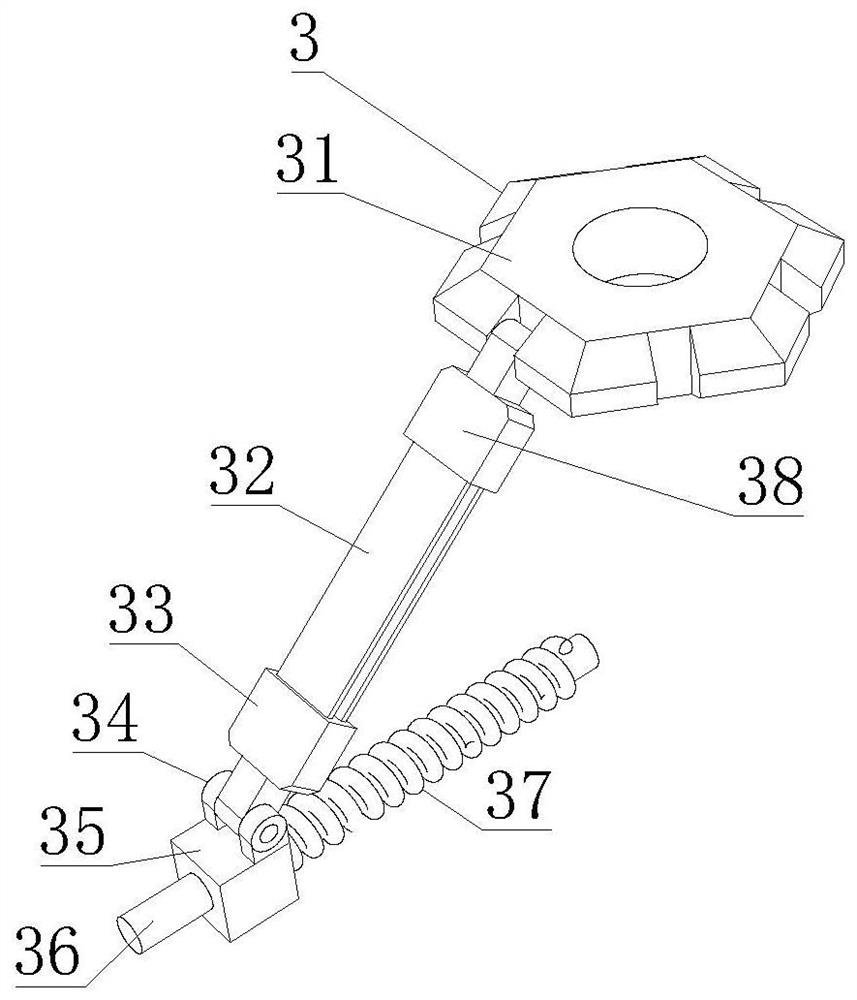

[0037] like Figure 1-7 As shown, the present invention provides a novel anti-seismic steel structure, comprising a supporting steel column 1, the lower side of the supporting steel column 1 is fixedly connected with a fixed base 4, and the outer surface of the fixed base 4 is fixedly connected with an anti-seismic mechanism 3, and the anti-seismic mechanism 3 Including an I-shaped plate mechanism 32 and a vibration-damping ring mechanism 34, the I-shaped plate mechanism 32 includes a built-in shock absorbing bar mechanism 322, and the built-in shock absorbing bar mechanism 322 includes an octagonal ring 3227, and the inner side of the octagonal ring 3227 is fixedly connected with an elliptical ring piece 3228, the outer surface of the supporting steel column 1 is movably connected with a locking mechanism 5, the locking mechanism 5 includes a gear ring 510, the inner wall of the gear ring 510 is fixedly connected with a connecting block 511, the lower side of the anti-seismic ...

Embodiment 2

[0040] like Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the inner side of the elliptical ring piece 3228 is fixedly connected with a wave elastic piece 3226, and the side of the octagonal ring 3227 is fixedly connected with a connecting rod 3223. The interior of the rod 3223 is fixedly connected with a reinforced vertical rod 3222, and the two ends of the reinforced vertical rod 3222 are fixedly connected with a reinforced long rod 3221. The side is fixedly connected with a right curved elastic sheet 3225, and the right side of the right curved elastic sheet 3225 is fixedly connected with the outer surface of the reinforced long rod 3221, and the outer side of the built-in shock absorber mechanism 322 is fixedly connected with an I-shaped board shell 321.

[0041] In this embodiment, the frame of the internal structure is composed of the reinforced long rod 3221, the reinforced vertical rod 3222 and the c...

Embodiment 3

[0043] like Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the lower end of the I-shaped plate mechanism 32 is fixedly connected with a lower end cap mechanism 33, and the inside of the lower end cap mechanism 33 is provided with an I-shaped groove 331, The right end of the lower end cap mechanism 33 is internally connected with an orbiting shaft 332. The damping ring mechanism 34 includes a fan-shaped elastic steel sheet 345. One side of the fan-shaped elastic steel sheet 345 is fixedly connected with a connecting ring 346. The inner wall of the connecting ring 346 is connected to the orbiting shaft. The outer surface of the shaft 332 is rotatably connected, the outer side of the connecting ring 346 is fixedly connected with a damping spring 344, and the other side of the damping spring 344 is fixedly connected with a damping ring shell 341, and the inner wall of the damping ring shell 341 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com