Novel prefabricated box girder loading operation method

A box girder and girder installation technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problem of idle single-girder single-door beam handling beam machines in enterprises, inability to use new and old equipment together, and inability to span low-level beam transport vehicles. and other problems to achieve the effect of reducing the risk of hoisting operations, saving fuel consumption, and avoiding idle scrap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

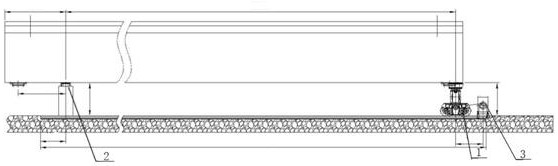

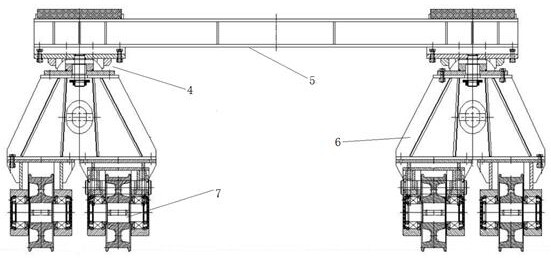

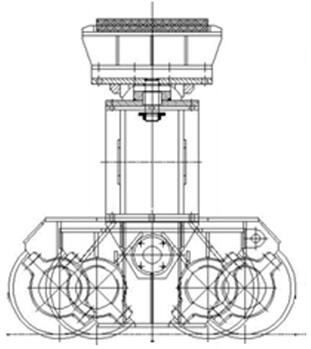

[0041] Such as figure 1 Among them, the beam loading trolley 1, the fixed beam platform 2 and the winch 3 arranged in the beam loading platform; figure 2 and image 3 They are the left view and the top view of the beam loading trolley 1, respectively. The beam loading trolley 1 is an existing product, and its structure includes a spherical joint support 4, a beam 5, a bracket 6, and a traveling steel wheel 7; Figure 4 It is a schematic diagram of the concrete buttress for the beam loading platform.

[0042] The specific embodiment of the beam loading platform operation of the present invention, in conjunction with such Figure 5 to Figure 10 To further illustrate the present invention, the devices used include a fixed beam platform 2, a beam loading trolley 1, a beam handling machine 10, a beam transport vehicle 9, a jacking device, a front camel beam trolley, a rear camel beam trolley, and a front camel beam trolley. The beam trolley and the rear camel beam trolley belon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com