Pharmacy trough type mixing machine

A trough mixer and mixing box technology, which is applied to mixers, mixers with rotating stirring devices, mixer accessories, etc., can solve problems such as easy accumulation of materials, unfavorable material pouring, and increased labor intensity of staff, and achieve Reduce the contact area and friction, improve the comprehensiveness of cleaning, and avoid the effect of incomplete cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

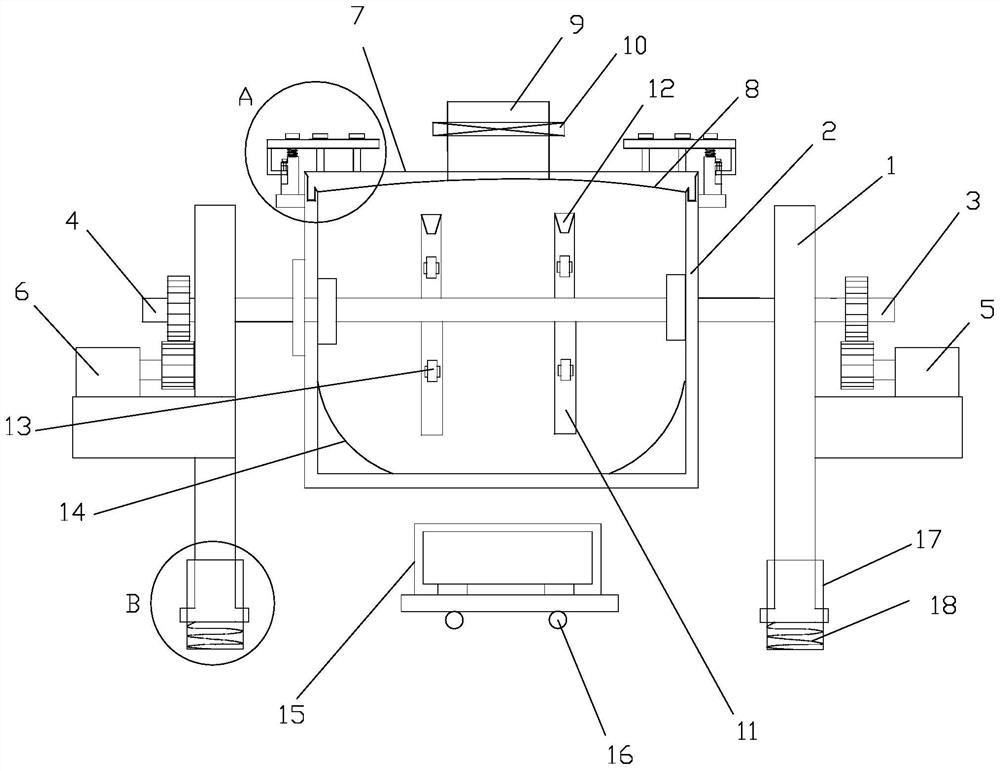

[0057] Such as Figure 1-Figure 7 As shown, a pharmaceutical trough mixer includes a mixing box 2 and a support frame 1, the mixing box 2 is rotatably arranged on the support frame 1, and the top of the mixing box 2 is connected with a detachable The box cover 7 is connected, and the box cover 7 is provided with a discharge port 9 communicating with the mixing box 2, and a first control valve 10 is provided at the discharge port 9.

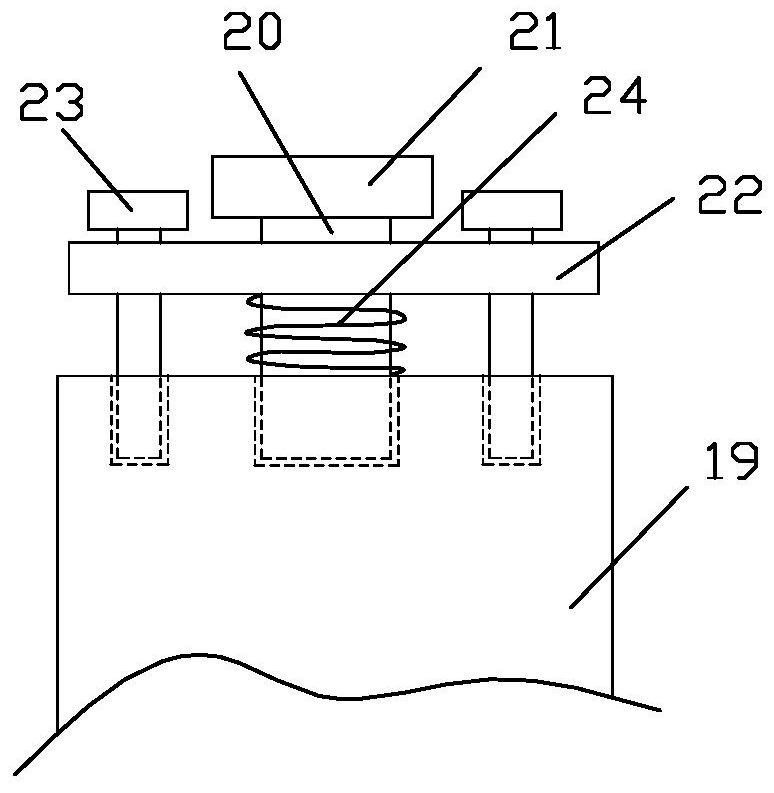

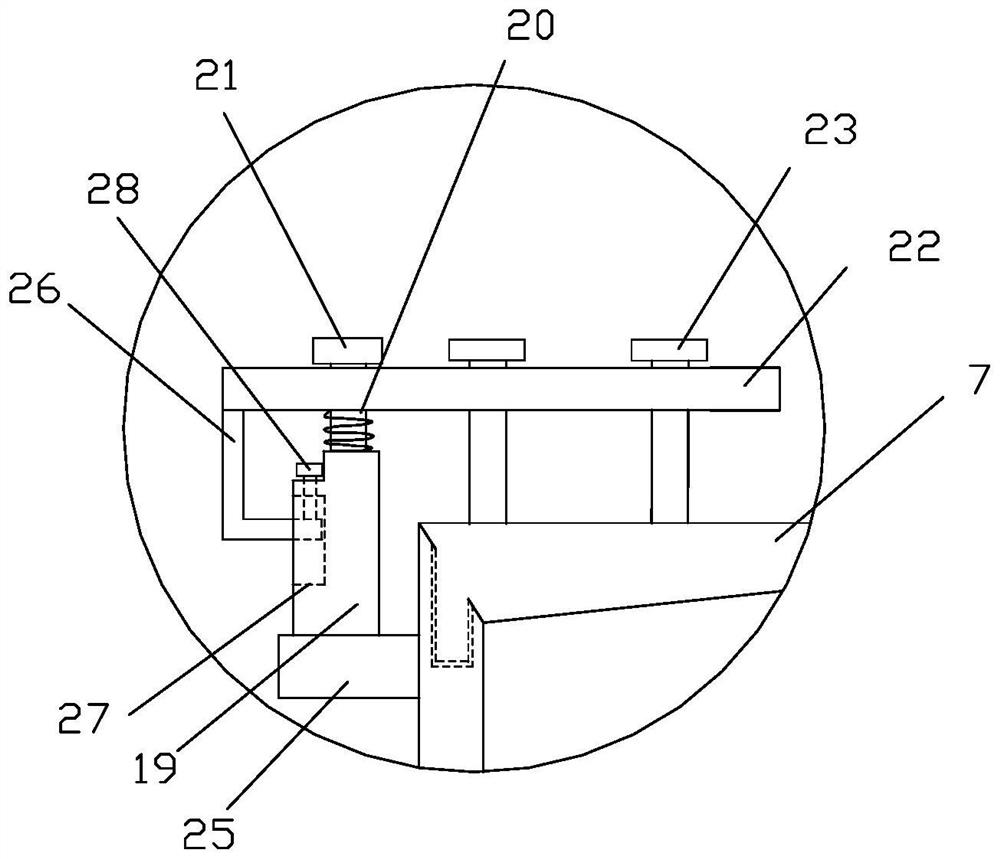

[0058] Described connection assembly comprises support column 19 and hold-down plate 22, and one end of described support column 19 is fixedly connected with the outer wall of mixing box 2 by column holder 25, and its other end is provided with the guide rod 20 that is threadedly connected with it, and described One end of the compression plate 22 is sleeved on the guide rod 20, and the other end is provided with a compression screw 23 threaded therewith, and the end of the compression screw 23 is embedded in the case cover 7 and is threaded with ...

Embodiment 2

[0064] Such as Figure 1-Figure 7 As shown, the same parts of this embodiment and Embodiment 1 will not be repeated, and the difference is:

[0065] The inside of the mixing box 2 is penetrated with a stirring shaft 3, the stirring shaft 3 is provided with a stirring fin 11, the stirring fin 11 is arranged perpendicular to the stirring shaft 3, and the end of the stirring fin 11 away from the stirring shaft 3 is provided with an arc Teeth 12 to improve the stirring effect. The stirring fins 11 are arranged around the circumference of the stirring shaft 3 to form a plurality of stirring fin groups, and a plurality of stirring fin groups are arranged along the axial direction of the stirring shaft 3 . The multiple stirring fins 11 in the same stirring fin group have different lengths to improve the stirring effect.

[0066] The support frame 1 is provided with a first drive motor 5 and a second drive motor 6, and the first drive motor 5 is connected to the stirring shaft 3 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com