Online insulation tester

An insulation tester and tester technology, applied in instruments, measuring devices, measuring electrical variables, etc., can solve the problems of inability to see the coil with the naked eye, broken coils, invisible coils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

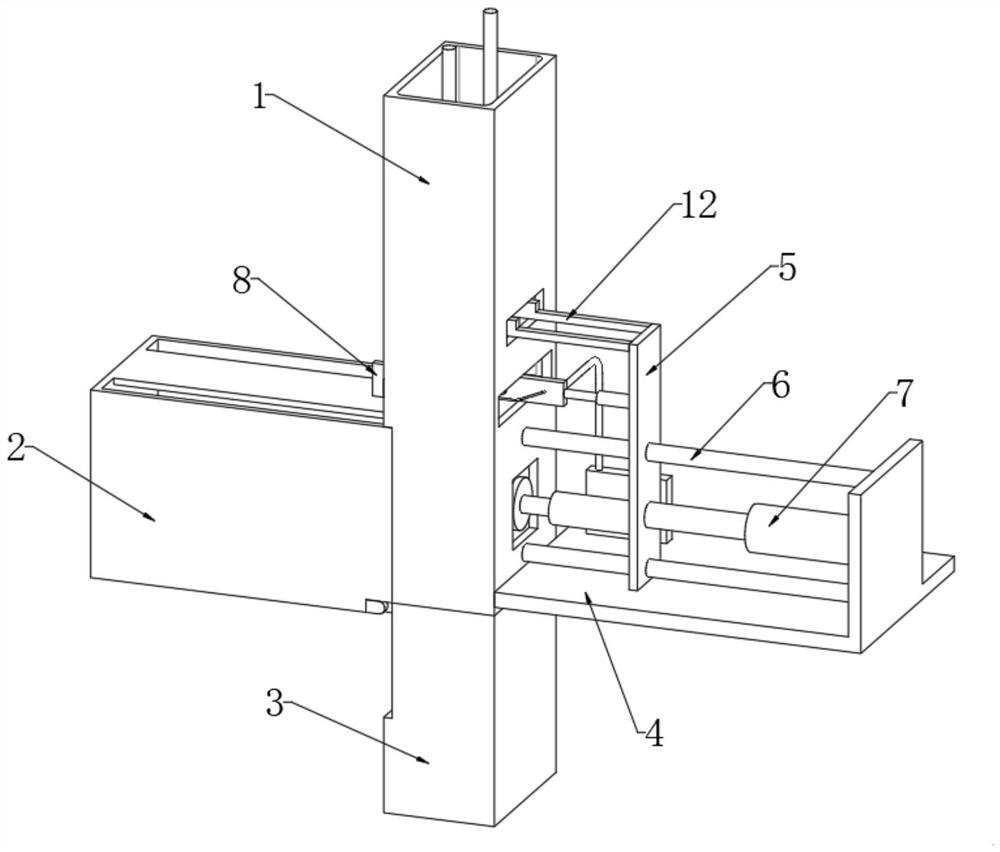

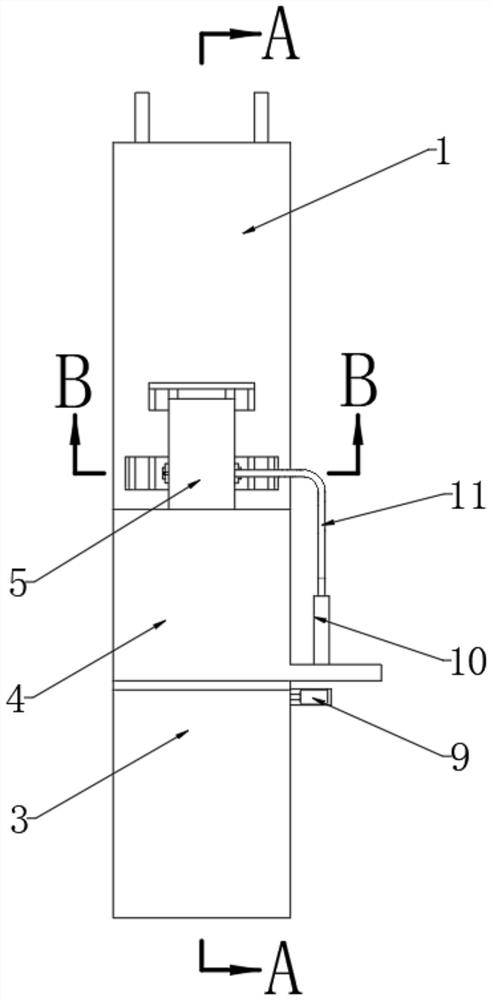

Image

Examples

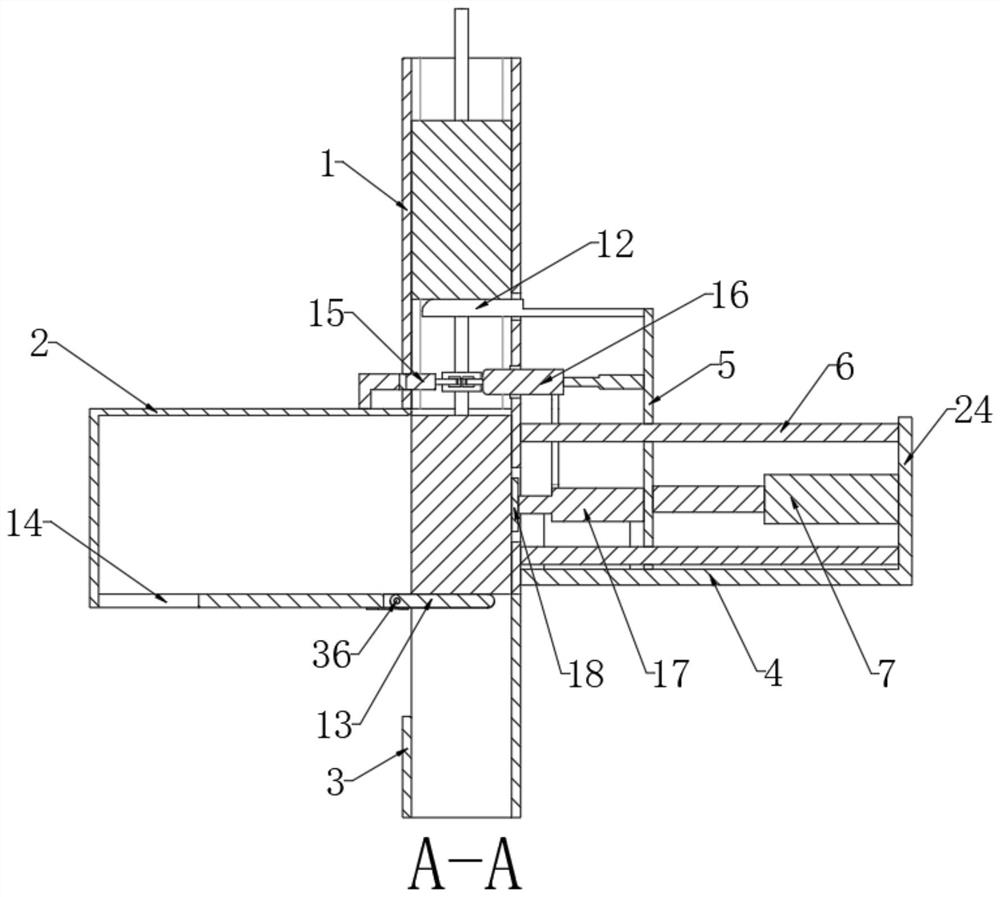

Embodiment 1

[0039] The control mechanism includes a second mounting block 16 that is slidably connected to the second mounting plate 5. The second mounting block 16 can enter the inside of the feed pipe 1. The outer wall of the second mounting block 16 is hinged with two first transmission rods 22. The ends of each first transmission rod 22 are hinged with a third mounting block 20, the outer walls of the two third mounting blocks 20 are hinged with a second transmission rod 23, and the two second transmission rods 23 are jointly hinged with a first mounting block 20. Mounting block 15, the first mounting block 15, the second mounting block 16, the third mounting block 20, the first transmission rod 22 and the second transmission rod 23 form a four-bar linkage mechanism, and the two third mounting blocks 20 face each other The outer walls of each are fixedly connected with a first transmission patch 21, and the two first transmission patches 21 are respectively electrically connected to th...

Embodiment 2

[0047] The control mechanism includes a mounting seat 25 fixedly connected to the outer wall of the second mounting plate 5, the bottom of the mounting seat 25 is provided with a first chute 34, and the inner wall of the first chute 34 is slidably connected with a first slide block 28, the first slide The bottom of the block 28 is fixedly connected with a long board 29, and the bottom of the long board 29 is fixedly connected with two second transmission patches 30, and the two second transmission patches 30 are respectively electrically connected with two transmission lines 11, and also includes driving two The second transmission patch 30 is downwardly close to the pulling mechanism at the top of the pin of the inductance to be detected, and further includes a driving mechanism for displacing the third mounting board 24 to the top of the pin of the inductance to be detected.

[0048] Such as Figures 6 to 8 As shown, when the inductance enters the inner bottom of the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com